Flammable vapor ignition resistant water heaters, Symptom probable cause corrective action, Service procedure – Bradford White 65T-65FB-3X User Manual

Page 4: Pilot will not light, Not enough hot water

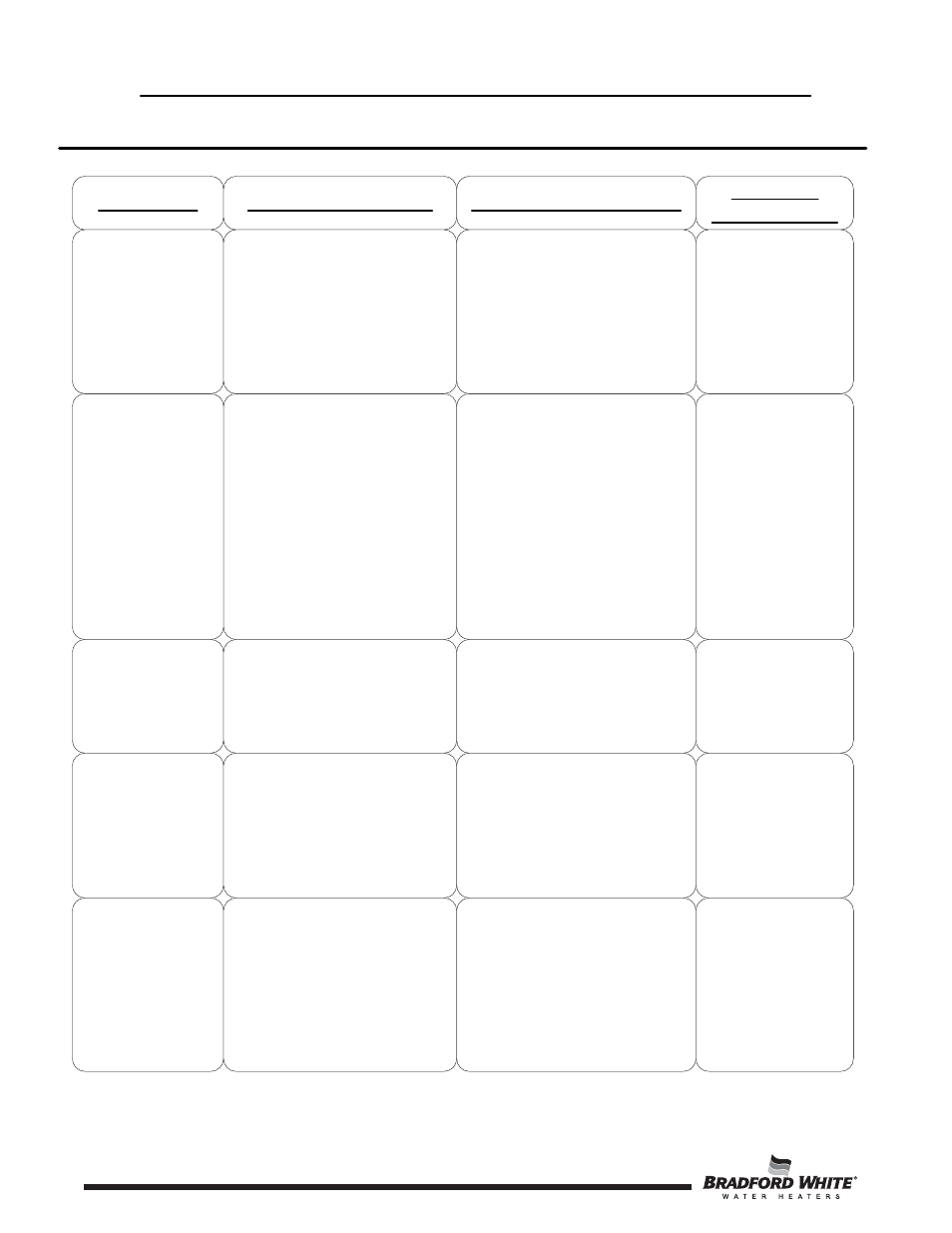

White Rodgers/Robertshaw Gas Valve Troubleshooting Chart

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Pilot Will Not Light

1. No incoming gas or too low gas

pressure.

2. Gas control knob set to wrong position.

3. Pilot light button not being fully

depressed when attempting to light pilot.

4. Pilot orifice or pilot tube is obstructed or

kinked.

5. Pilot electrode not sparking to pilot.

6. Piezo igniter not functioning.

1. Poor thermocouple connection at

combination thermostat/gas valve.

2. Thermocouple not fully engaged in pilot

assembly bracket.

3. Pilot flame is not fully enveloping the

thermocouple “hot” junction.

4. Weak or defective thermocouple.

5. Open ECO on combination thermostat/

gas valve.

6. Defective magnet in combination

thermostat/gas valve.

7 Resettable thermal switch has opened.

Pilot Will Not

stay lit

when button is

released

Pilot will light but

the main burner

will not come on

1. Combination thermostat/gas valve set too

low for desired water temperature.

2. Combination thermostat/gas valve

temperature is satisfied.

3. Insufficient gas supply or low gas

pressure.

4. Combination thermostat/gas valve has

wide differential or is out of calibration.

Pilot goes out

periodically (after

heating cycles,

once a day, once

a week etc.)

1. Insufficient combustion air supply.

2. Incorrect, clogged vent system/ vent

terminal or location.

3. Inconsistent gas supply or gas pressure.

Not enough hot

water

1. Combination thermostat/gas valve set too

low for desired water temperature.

2. Cold inlet water temperature is very cold.

3. High demand periods.

4. Incorrectly sized water heater for

application.

5. Combination thermostat/gas valve is out

of calibration/not functioning.

6. Out of spec dip tube is diluting hot water

with cold water.

1. Turn on gas supply and/or check line

pressure.

2. Review lighting instruction. Set

combination/thermostat

gas valve to correct position.

3. Review lighting instruction. Fully depress

pilot lighting button.

4. Clean, repair or replace.

5. Verify correct electrode position. Replace

pilot assembly.

6. Replace Piezo igniter.

1. Check connection at combination

thermostat/gas valve. Proper tightness

should be finger tight plus ¼ turn.

2. Inspect thermocouple to ensure that it is

fully engaged into pilot bracket.

3. Adjust tip of thermocouple to be fully

engulfed by pilot flame.

4. Check thermocouple and replace if

necessary.

5. Check ECO continuity and replace

combination thermostat/gas valve if

necessary.

6. Check magnet operation and replace

combination thermostat/gas valve if

necessary.

7. Determine cause of switch activation. To

reset, depress button on resettable thermal

switch located on inner door.

1. Adjust temperature dial on combination

thermostat/gas valve.

2. Check temperature dial setting on

combination thermostat/gas valve.

3. Check gas supply and line pressure.

4. Check combination thermostat/gas valve

for proper operation, replace if

necessary.

1. Verify adequate combustion air is available

to the unit. Check and clear Jacket slot

openings of any dirt, dust, restrictions or

other obstructions. Inspect flame arrestor

plate and clean with stiff bristled brush

and/or vacuum to remove any debris

accumulation.

2. Check venting for proper sizing and proper

operation

3. Check gas supply and line pressure.

1. Check dial on combination thermostat/gas

valve.

2.Extremely cold water going into the heater

will decrease the amount of hot water

produced. It may be necessary to temper

incoming water supply.

3. Adjust high demand usage.

4. Contact Plumbing professional.

5. Check combination thermostat/gas valve

for proper operation, replace if

necessary.

6. Inspect dip tube and replace if necessary.

SERVICE

PROCEDURE

1. See Service Procedure

RG-V, Page 12.

4. See Service Procedure

RG-III, Page 10.

5. See Service Procedure

RG-III, Page 10.

6. See Service Procedure

RG-IV, Page 11.

4. See Service Procedure

RG-II, Page 8

5. See Service Procedure

RG-V, Page 14

6. See Service Procedure

RG-V, Page 13

2. See Installation &

operation manual.

3. See Service Procedure

RG-V, Page 12

4. See Service Procedure

RG-V, Page 12

1. See Service Procedure

RG-VIII, Page 22

3. See Service Procedure

RG-V, Page 12

5. See Service Procedure

RG-V, Page 12

6. See Service Procedure

RG-IX, Page 23

Flammable Vapor Ignition Resistant Water Heaters

4

4

4

- 50T-65FB-3X 65T-65FB-3N 50T-65FB-3N M-2-XR65T6FSX M-2-XR504T6FSX M-1-XR403S6FSX M-4-60T6FSX M-4-5036FSX M-4-403S6FSX M-4-40T6FSX M-4-30T6FSX M-I-60T6FSX M-I-504S6FSX M-I-50L6FSX M-I-5036FSX M-I-404T6FSX M-I-403S6FSX M-I-40T6FSX M-I-30S6FSX M-I-303T6FSX M-I-30T6FSX M-2-XR65T6FBN M-2-XR504T6FBN M-1-XR403S6FBN M-4-60T6FBN M-4-5036FBN M-4-403S6FBN M-4-40T6FBN M-4-30T6FBN M-I-60T6FBN M-I-504S6FBN M-I-50L6FBN M-I-5036FBN M-I-404T6FBN M-I-403S6FBN