B&C Technologies DI-475 Industrial User Manual

Page 16

F. ELECTRICAL INFORMATION

1. Electrical Requirements

It is your responsibility to have all electrical connections made by a properly licensed and

competent electrician to assure that the electrical installation is adequate and conforms with

local and state regulations or codes. In the absence of such codes, all electrical connections,

material, and workmanship must conform to the applicable requirements of the national

electrical code ANSI/NEPA NO. 70-latest edition.

IMPORTANT:

Failure to comply with these codes or ordinances, and/or

the requirements stipulated in this manual con result in

personal injury or component failure.

NOTE:

Component failure due to improper installation will VOID

WARRANTY.

Each dryer should be connected to an independently protected branch circuit. The dryer must

be connected with copper wire only. Do not use aluminum wire, which could cause a fire

hazard. The copper conductor wire/cable must be of proper amperecity and insulation in

accordance with electric codes for making all service connections.

NOTE:

The use of aluminum wire will VOID WARRANTY.

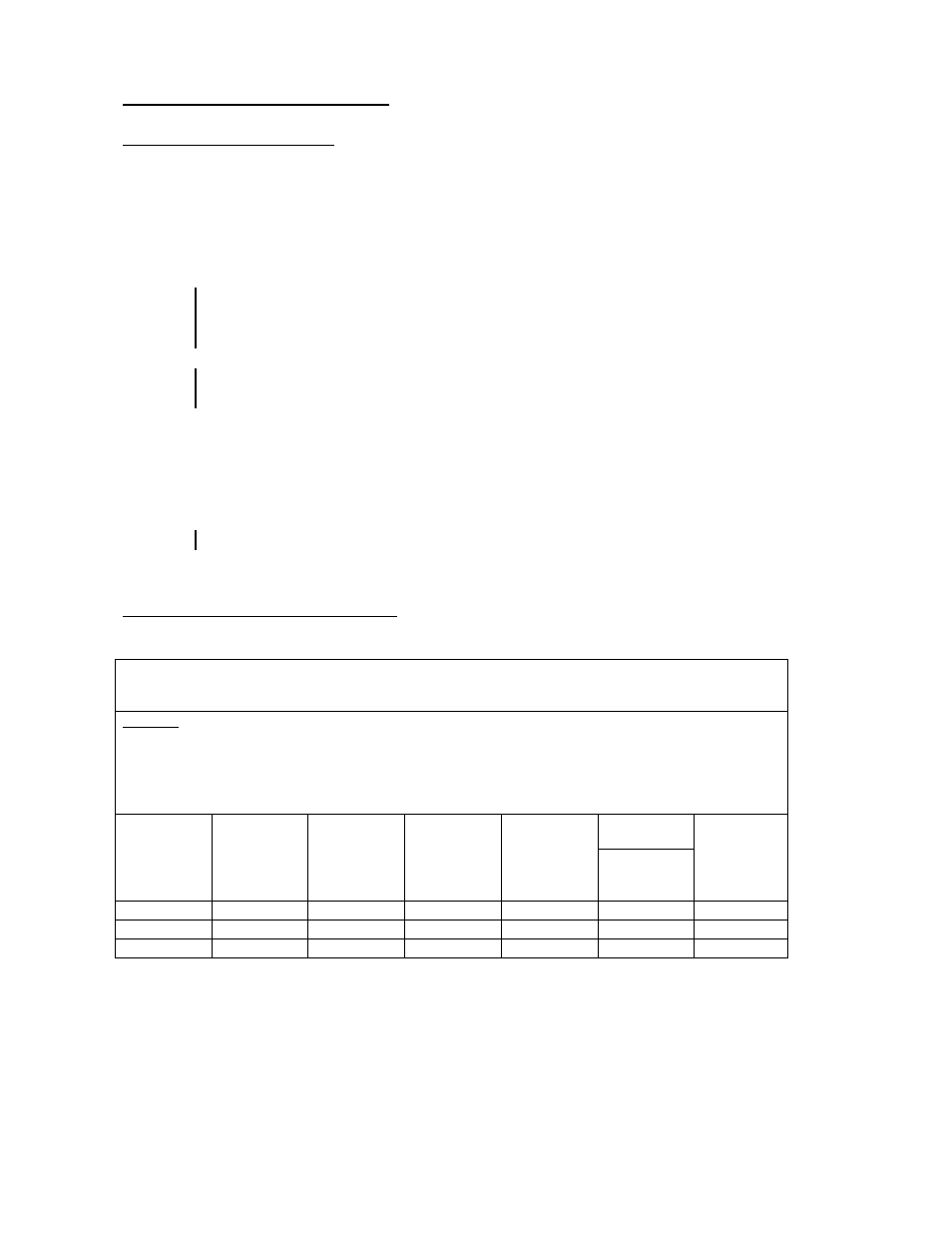

2. Electrical Service Specifications

DA-475, 20Hp Blower, Reversing, 3 Motor

Electrical Service Specifications (Per Dryer)

NOTES:

A. Fuse ratings are dual element-time delay-current limiting, class RK1 or RK5 ONLY.

B. Circuit breakers are thermal magnetic (industrial) type

ONLY

. For others, calculate /

verify correct breaker size according to appliance amp draw rating and type of breaker

used.

C. Circuit breakers for 3 dryers

must be

3-pole type.

SERVICE

PHASE

WIRE

APPROX.

MINIMUM

FUSING

CIRCUIT

VOLTAGE

SERVICE

AMP DRAW WIRE SIZE*

Dual

Element

Time Delay

BREAKER

208

3

3/4

87

8

125

125

380

3

3/4

48

6

60

90

416

3

3/4

44

6

60

90

* AWG Stranded Type Wire...for individual lengths longer than 100 feet.

The factory reserves the right to make changes in specifications at any time, without notice or

obligation.