Vetter Lifting bags 1 bar (14.5 psi) Test Equipment User Manual

Page 25

Page 24/28

2. Visual inspection Filling device

If heavily soiled, clean the bag and its accessories before starting the visual inspection.

S.Tec lifting bags are normally washed off with a lukewarm soap solution.

Never use a high-pressure cleaner!

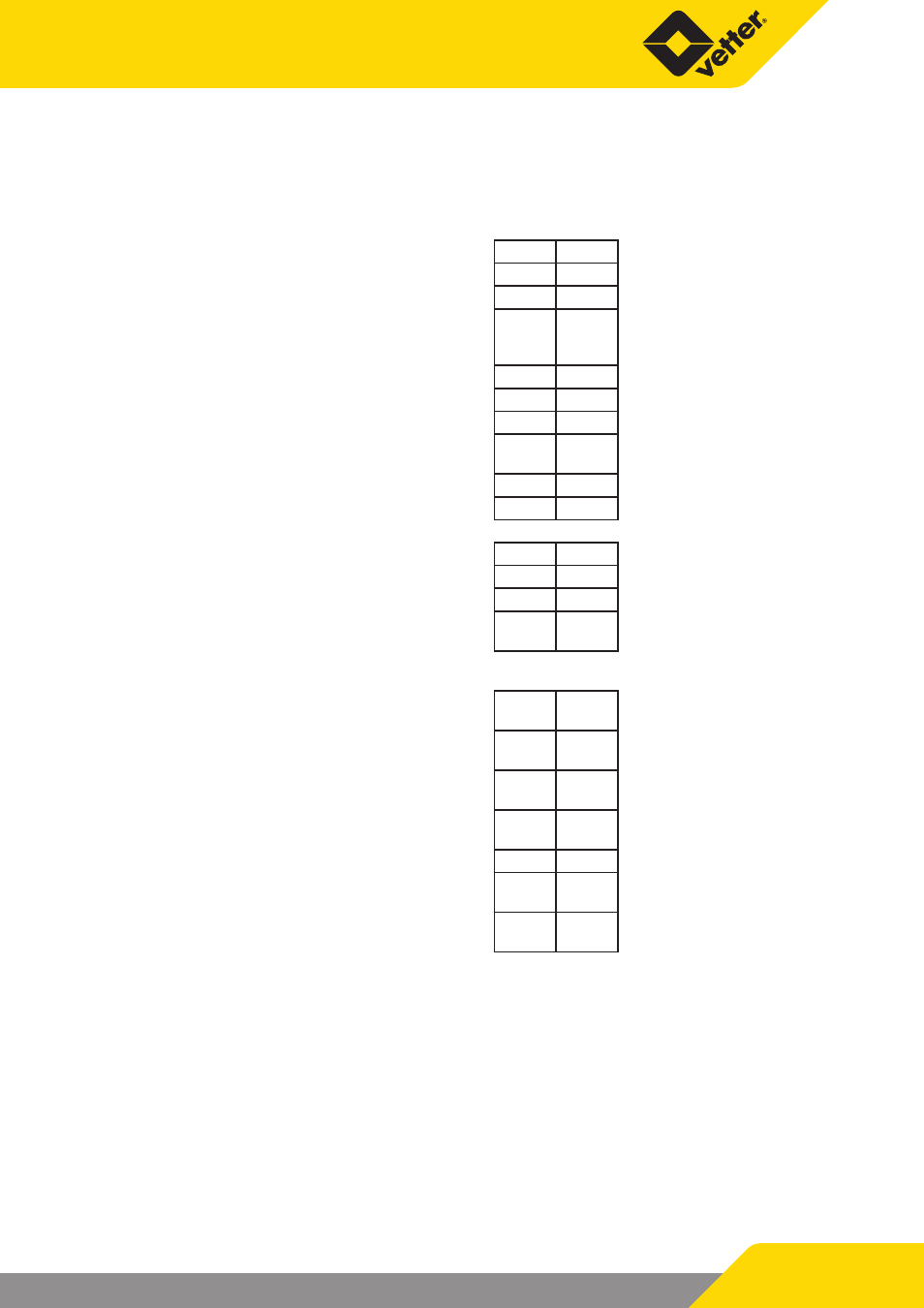

2.1

Pressure regulator

Yes

No

2.1.1 Inlet seal present

2.1.2 Bottle connection thread not damaged

2.1.3

Both manometers free of visible damage and are

marked with the marking of the max. operating over-

pressure

2.1.4 Manometer protective caps present

2.1.5 Pressure setting operates smoothly

2.1.6 Shut-off valve undamaged and operates smoothly

2.1.7 Air hose free of cracks, cuts, punctures, splinters or other

damages, e.g., hardenings, acid traces, etc.

2.1.8 Connection nipple does not have any visible damage

2.1.9 Hose assembly fixated

2.2

S.Tec Filling hose, 5/10 m, yellow/red

2.2.1 Connection nipple does not have any visible damage

2.2.2 Nipple does not have any visible damage

2.2.3 Coupling and nipple assembly fixated

2.2.4 Hose free of cracks, cuts, punctures, splinters or other

damages, e.g., hardenings, acid traces, etc.

2.3

S.Tec Controller

Dead-man switching

2.3.1 Inlet coupling (plug coupling) undamaged and functio-

nal

2.3.2 Control lever free of external damages and operate

smoothly

2.3.3 Manometer with marking at maximum operating over-

pressure (10 bar/145 psi)

2.3.4 Safety valve free of visible damage and furnished with

lead seals

2.3.5 Housing is free of visual damage

2.3.6 Labels of the controller are available and can be clearly

read

2.4.7 Output couplings free of visual damage and functionally

operational

Caution! If any kind of doubts concerning the safety arise at this time or at

any later time during the test, abort the test and send the bag including

the equipment to the manufacturer for further testing.