Vetter test equipment for lifting bags – Vetter Lifting bags 1 bar (14.5 psi) Test Equipment User Manual

Page 16

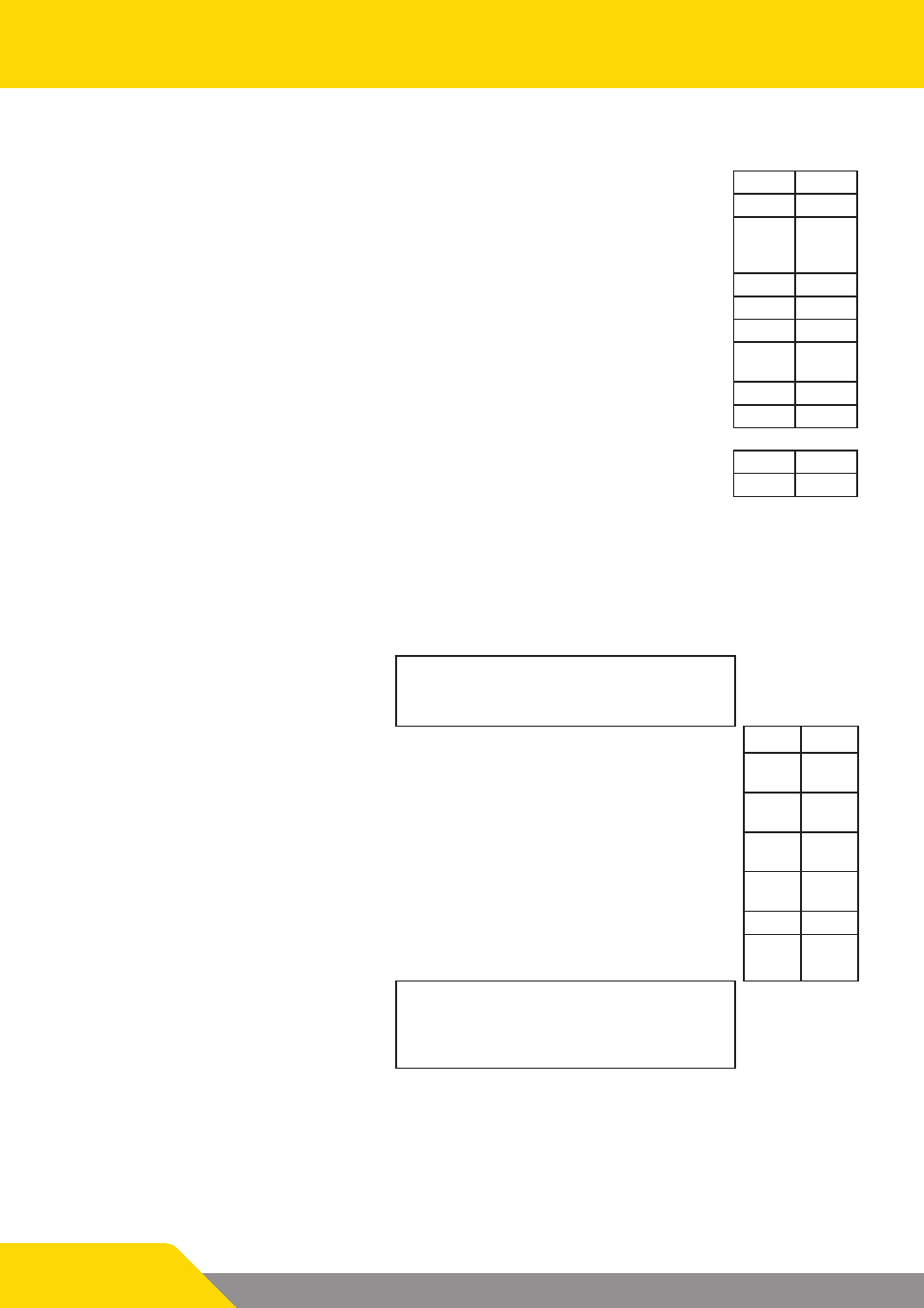

Vetter Test Equipment for Lifting Bags

Page 15/28

2.5

Pressure regulator

2.5.1 Inlet seal present

2.5.2 Bottle connection thread not damaged

2.5.3

Both manometers free of visible damage and are

marked with the marking of the max. operating over-

pressure

2.5.4 Manometer protective caps present

2.5.5 Pressure setting operates smoothly

2.5.6 Shut-off valve undamaged and operates smoothly

2.5.7 Air hose free of cracks, cuts, punctures, splinters or other

damages, e.g., hardenings, acid traces, etc.

2.5.8 Connection nipple does not have any visible damage

2.5.9 Hose assembly fixated

2.6

Set repair material

2.6.1 Adhesive, patches and roughening paper available

2.6.2 Adhesive useable, not dried out

Caution! If any kind of doubts concerning the safety arise at this time or at

any later time during the test, abort the test and send the bag including

the equipment to the manufacturer for further testing.

3. Function test

Caution! Perform only if the visual inspection in Point 2 and the test of the equipment

did not result in any complaints.

3.1

Connect pressure regulator to the compressed-air bottle.

Close the Shut-off valve on the pressure reducer.

Open the compressed-air bottle valve.

Yes

No

3.1.1

Primary pressure manometer indicates (pressure in the

compressed-air bottle)

3.1.2

Back pressure manometer indicates (possibly increase

pressure on the control knob)

3.1.3

Pressure can be regulated across the entire adjustment

range

3.1.4

Safety valve remains leakproof at the set maximum

pressure.

3.1.5

Shut-off valve on the pressure-reducer outlet seals tight

3.1.6

At a set pressure of approx. 5 bar, the pressure does not

increase significantly within 5 min.

Connect the pressure reducer to the controller with an air

hose

Open the pressure reducer shut-off valve. Set the pressure

to approx. 2 bar.