Tjernlund DJ-3, D-3, HD, I, IL, XL Draft Inducer 8504003 Rev A 07/00 User Manual

Page 3

INSTALLATION RESTRICTIONS

Failure to install, maintain and/or operate the Draft Inducer in accordance with manufacturer's instructions may result in conditions

which can produce bodily injury and property damage.

The Draft Inducer must be installed by a qualified installer in accordance with these instructions and all local codes or in their absence

in accordance with the latest editions of The National Fuel Gas Code (NFPA #54), Installation of Fuel Burning Equipment (NFPA 31),

Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances (NFPA 211), The National Electrical Code (NFPA#70) and the

Occupational Safety and Health Act (OSHA) when applicable. Improper installation can create a hazardous condition such as an

explosion, fire, electrical shock or carbon monoxide poisoning resulting in property damage, personal injury or death.

1. The Draft Inducer shall not be used on condensing heating equipment.

2. Oil burning installations and gas-fired units without a draft hood / diverter should include a barometric draft regulator.

3. The Draft Inducer motor shaft must be mounted horizontally to prevent motor bearing wear.

4. The Draft Inducer shall not be installed where flue gas temperatures exceed 575

O

F at the Draft Inducer Inlet. Ambient room

temperatures must not exceed 104 degrees F.

Flue gas temperature verification:

A) Consult appliance manufacturer for temperature of gases at the appliance outlet after dilution by draft hood, draft diverter or

barometric draft control.

AND

B) Measure temperature of flue gases at the Draft Inducer inlet at time of installation. Temperature should be measured after

appliance and Draft Inducer have operated for at least 10 minutes, allowing flue gas temperature to stabilize.

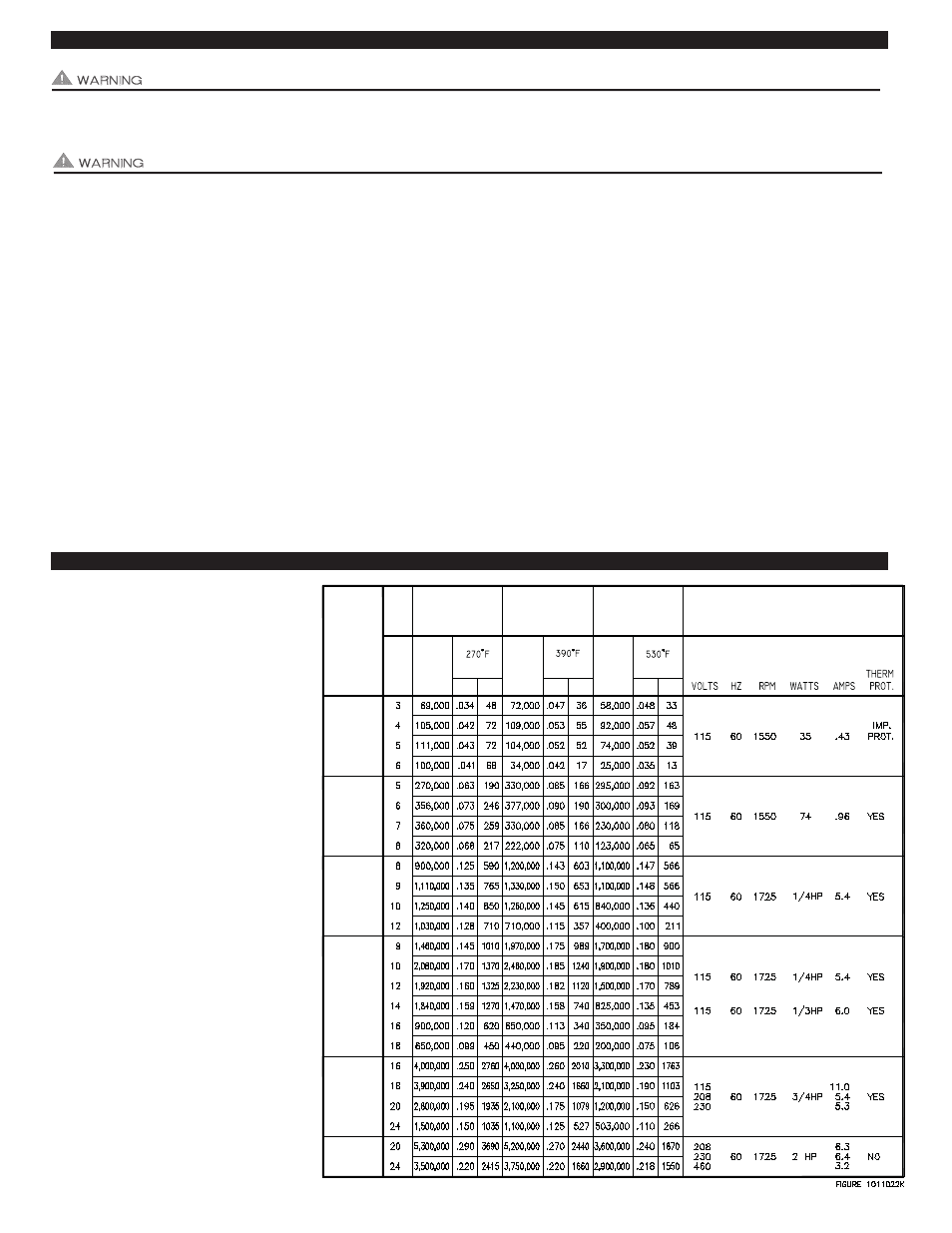

DRAFT INDUCER SELECTION TABLE

2

1. Inputs shown are believed to be

maximum capacities for inducers when

mounted on pipe sizes shown for

ordinary jobs where a moderate amount

of mechanical induced draft is required.

2. Consideration is given to typically

higher static pressure requirements for

larger installations, for the type of fuel

burned and for the type of draft control

installed.

3. Where pressure requirements are

unknown or believed to be unusually

severe, ask for complete performance

curves or consult factory.

4. All ratings have been developed in our

testing and research department and

have been approved by a nationally

known independent testing laboratory.

Certification is available upon request.

5. Heating capacities shown are for 1000

BTU per cubic foot natural gas and for

139,000 BTU per gallon No. 2 fuel oil.

Consult factory for capacities with other

fuels. Heating capacities are based on

typical combustion efficiencies and

allow for approximately 5 percent

ambient air drawn into inducer to

cool motor and drives.

6. Draft Inducers should be installed

in single wall vent pipe in order

to insure proper performance.

DJ-3

D-3

I

IL

XL

HD

GAS FIRING

WITH

DRAFT HOOD

MODEL

GAS FIRING

WITH

BAR. DRAFT

CONTROL

OIL FIRING

WITH

BAR. DRAFT

CONTROL

HEATER

BTU

INPUT

HEATER

BTU

INPUT

HEATER

BTU

INPUT

S.P. CFM

CFM

S.P.

CFM

S.P.

FLUE GAS

FLUE GAS

FLUE GAS

ELECTRICAL

DATA

IN.

SIZE

PIPE