Smart Power Systems HR-30 User Manual

Page 40

Smart Power

®

Systems

A. C. MODULAR GENERATOR SYSTEM

Page 39 of 50

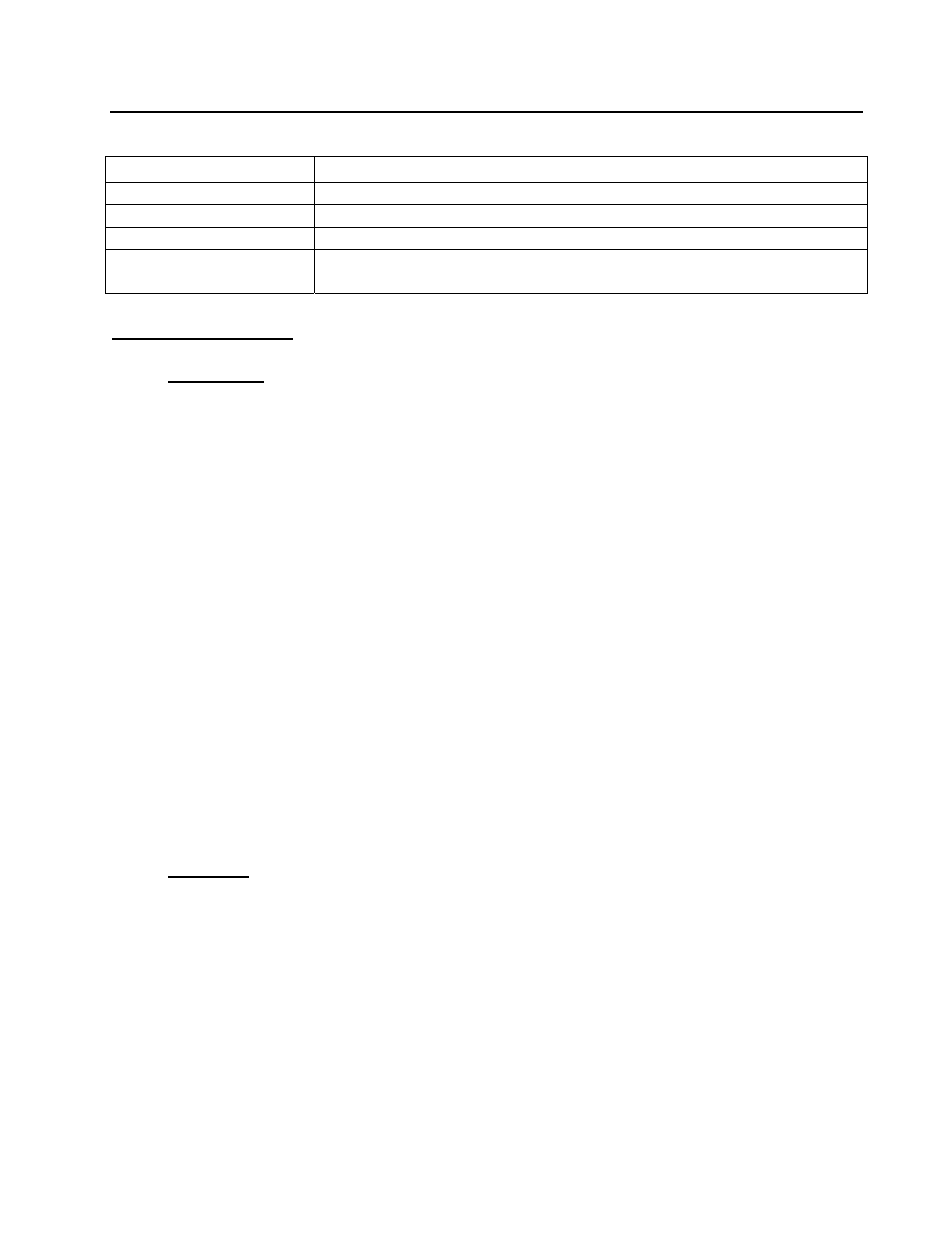

Note: The fault “Classes” are defined in the table below:

Class Meaning

Service Warning

Normal maintenance needs to take place.

Alarm

A condition requires the immediate attention of the operator.

Shutdown

A condition causes the immediate shutdown of the generator.

Override

A condition that will cause the generator to be shut down in 30

minutes unless explicitly overridden by the operator.

Table 3

Hydraulic Problems:

1.

Cavitation:

Cavitation is caused by trying to pump more fluid than is available at the

pump inlet due to system restrictions. Pump cavitation sounds like “marbles”

passing through the pump. Conditions frequently associated with cavitation are the

following:

a. Too many restrictive fittings such as elbows and reducers on the pump inlet

hose.

b. Tight bends or kinks in pump inlet hose and/or tubing.

c. Insufficient tray height above the pump, resulting in low head pressures.

d. Under sized pump inlet hose (minimum pump inlet hose size is 1”).

e. Excessively long inlet hose (may be corrected by using larger hose).

f. Cold hydraulic fluid.

Finding the cause and correcting it should stop cavitation.

Install a 0-25 psig gauge in line between inlet hose fitting and pump inlet port.

Engage PTO. Operate genset with no load for twenty minutes to purge air out of

the system. Observe the pressure reading. The pressure should always be

positive. If the pressure is not positive, system repair/rework is required.

2.

Aeration:

Aeration results from air being drawn into the system through leak paths or a

low fluid condition. Aeration makes a “growling” sound and produces visible

bubbles in the fluid stream and/or reservoir. Conditions frequently associated with

aeration are the following:

a. Air leaks in the pump inlet flow path.

b. Low fluid level allowing air to be drawn into the system.

Verify there are no air bubbles in the fluid by viewing inside the reservoir. If there

are air bubbles, check fluid level, tighten all fittings, and look for cracked fittings or

hose leaks on the pump inlet line. Replace any suspect parts and adjust fluid level.