Understanding dual pivot – Origin Live MK3C arms dual pivot User Manual

Page 2

Page2

Understanding dual Pivot

Your Origin Live arm has innovative bearings. Th

is is best

explained before going any further.

Dual pivot bearing design – why?

One of the many reasons that the Origin Live arms are

performance leaders is due to the dual pivot bearing,

on the horizontal axle (which governs the arms vertical

movement). Th

e design is similar in many respects to

uni-pivot – low friction and high decoupling which give

excellent defi nition and transparency. However uni-

pivots can be fi ddly to set up and because of their relative

instability exhibit a mediocre bass performance. Dual

pivots have all the advantages of uni-pivots but none of

the drawbacks. Vertical movement of the arm is handled

by the dual pivot and horizontal movement by our usual

highly specifi ed conventional bearings.

Floating bearings for horizontal rotation

Th

ere is a certain amount of “rocking movement” on

the yoke vertical axis. Some people mistake this for poor

bearing fi t but this is far from the case. Whilst most

arms use “rigid” bearing fi ts, Origin Live is unique in

employing a “fl oating” bearing design - this is actauly

much harder to engineer and does not cause alignment

errors as the bearings are self centering and factory

settings of the headshell take account of this.

Handles like a conventional gimballed

arm

You should handle the arm in exactly the same way as a

conventional gimballed arm. In other words you do not

need to worry about setting up azimuth. Th

e azimuth has

already been set, such that the headshell is parallel to the

arm mounting surface. We strongly recommend that you

never adjust the factory setting without our permission, as

this will invalidate the warranty. Correct azimuth setting

is tricky at the best of times and unless an extremely

careful record is kept on the original factory settings the

arm will probably end up not working correctly.

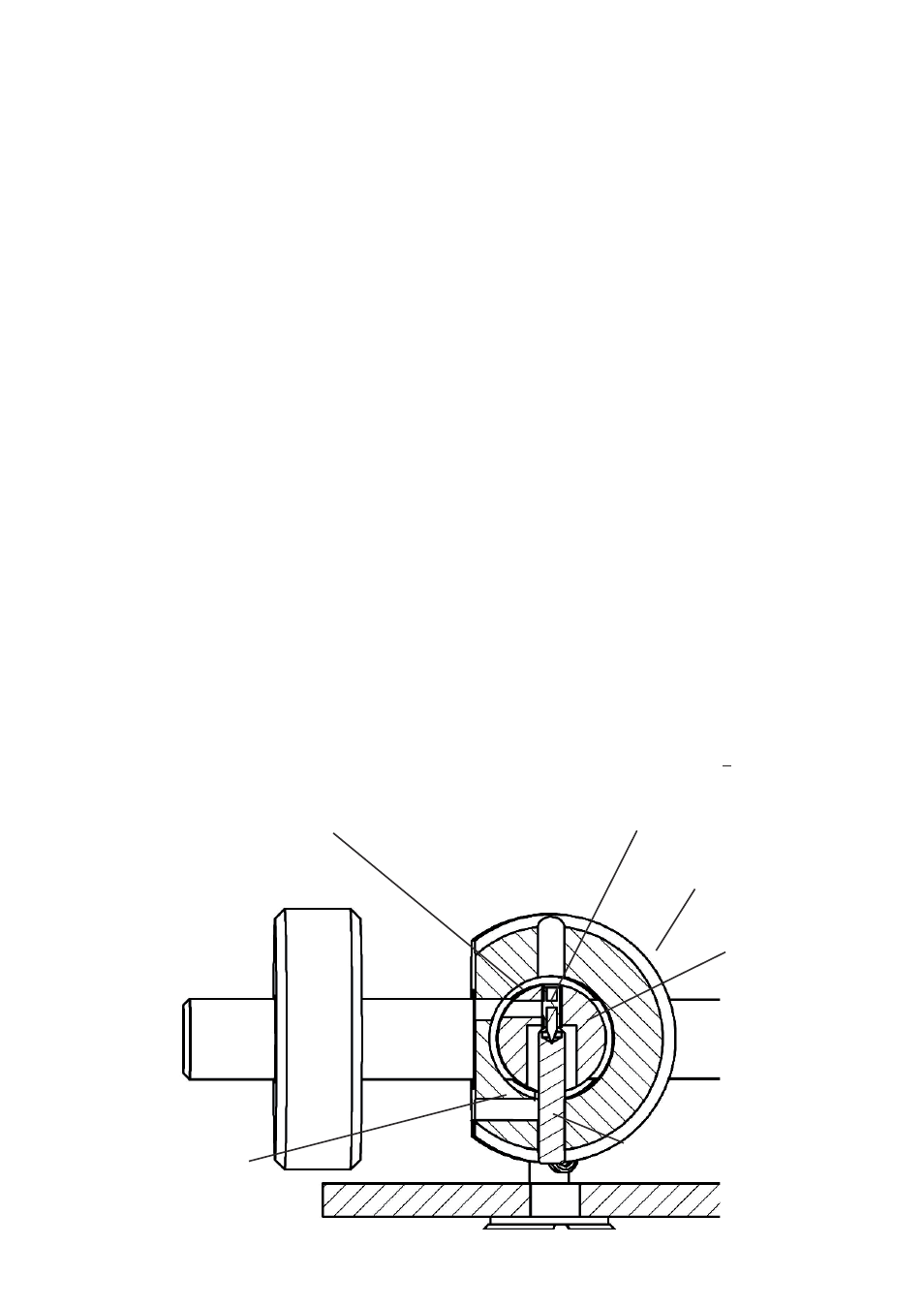

How dual pivot works

Th

e below illustration of the dual pivot bearing shows

how the horizontal axle is free to move a little in all

directions except downwards. Th

is may be a little

disconcerting until you become confi dent of the inherent

performance virtues delivered by this approach. It is also

reassuring to know that the arm cannot be knocked off it’s

bearings or come loose in any way. You can turn the arm

upside down and nothing will fall off as it would in the

case of a uni-pivot!

Th

e pivot bearings are designed to reduce friction to an

absolute minimum. In doing this there is a fi ne balance to

achieve both a robust design whilst maintaining extremely

low friction. In practice, the arm must have a slight degree

of movement due to a sharp tungsten point in a shallow

radiused bearing cup. Th

e alternative to this is a very

sharp point in a deep v shaped cup – this would certainly

restrain the movement of the point but would also

increase friction and potential fracture of the tips.

Th

e pivot points will “self centre” by sliding into the

bottom of the bearing cup. However the fi nal resting

place of the point may vary by 0.01mm or so. Th

is would

not be noticed without the use of a very accurate digital

stylus force gauge.

As the pivot position shifts fractionally it can cause the

tracking force to vary slightly, by around +0.06 grams

THREADED SPIKE

PILLAR CUP BEARING

PILLAR

CLAMPING

SCREW

Do not

touch

SPIKE CLAMPING SCREW

Do not touch

YOKE BARREL

END CAP