Origin Live Resolution MKI User Manual

Page 6

Page6

F I T T H E A R M C A B L E C L I P

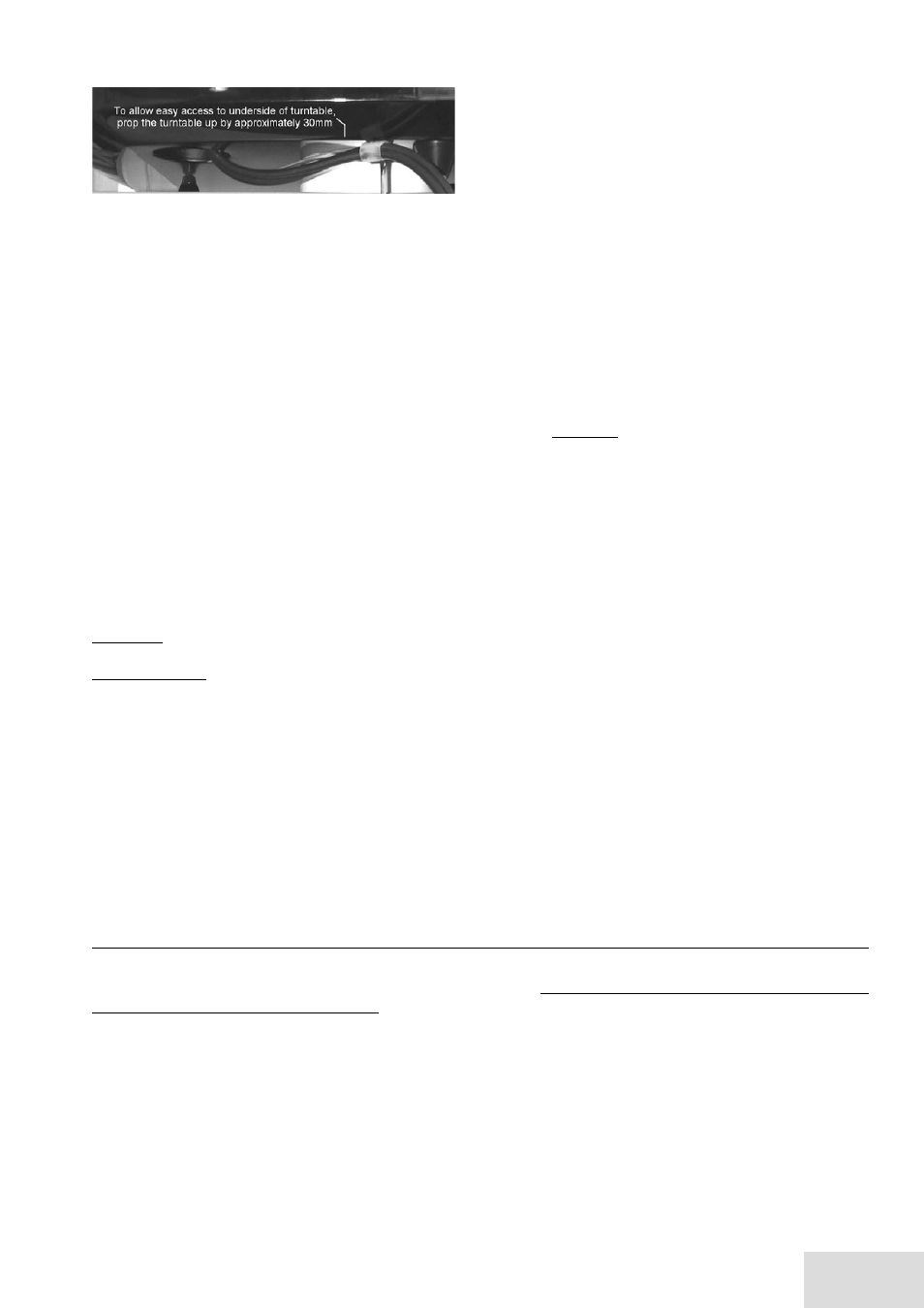

Fasten the arm cable to the underside of the plinth near the rear foot using the P-clip and screw provided. Leave a slight droop in the cable

between the arm and the cable clip so that it isn’t “tight”. The cable clip is important for best performance as it “earths” vibration in the arm.

If your arm has an earth lead then it should be connected to the earth of your pre-amplifier or amplifier. The earth lead is best separated

slightly from the arm signal leads so do not wind it around them for best performance. Avoid pulling the external arm wires as they are not

indestructible and can become detached if excessive force is used to manipulate them.

F I T T H E S U B - P L A T T E R & P L A T T E R

With the bottle supplied, run approx 5 drops of oil into the top of the bearing house.

Wipe the sub-platter spindle surface to ensure that it is absolutely clean and very gently insert the sub-platter into the bearing

house (If the oil does not overflow when the spindle touches the bottom then try 2 drops at a time till you just achieve overflow

- wipe away excess oil) and then place the platter on top.

NOTE:

The bearing needs a few minutes to “run in” and should run silent when truly vertical and full of oil - if it doesn’t do so, there has

probably been contamination with dust and you will need to clean it out with a lint free paper towel or similar wrapped around a

thin rod. If you do this, be sure to also wipe the oil off the spindle as this also may contain microscopic contamination that is not

visible.

Fit the belt over the motor pulley and sub-platter.

Set the belt tension by positioning the motor pod relative to the turntable. You will find that the sub-chassis can rotate very slightly on the

plinth – rotate it so that the bearing moves towards the motor pod. The centre of the motor pulley should be approx 122mm to 125 mm

to the centre of the bearing house but this can vary depending on belt length variations.

N O T E :

It is common for people to set the belt tension too tight, which can slightly degrade performance. The optimum setting is where there is

enough tension to turn the platter without audible wow and flutter but no more. This may take some experimentation.

It also aids performance to clean the belt and all the running surfaces with mentholated or surgical spirit.

Finally ensure that the motor pod is not touching the plinth.

F I T & L E V E L T H E P L A T T E R

Top and bottom spring adjusters are provided on some sub-chassis for versatility but the new top spring adjuster shown in photo 2 does not

need a bottom spring adjuster and so it is ommited.

Try to initially level the sub-chassis by rotating the top spring adjuster. The plastic pods play no part in the levelling process. Note: both top

and bottom spring height adjusters work by rotating them – you can use these, either in combination or one at a time to achieve level. It

doesn’t matter which you use, providing the spring support bolt does not “bottom” inside the top spring adjuster. Remember not to let the

bottom spring adjuster touch the plinth.Check that the platter is level – if it is not, then level it by levelling the table or surface that the deck

stands on. If this is not possible then use a combination of the spring height adjuster and small cork disc(s) placed under one of the feet of

the deck.

This may not seem the most elegant solution but threaded feet adjusters sacrifice sound quality significantly.