Mounting origin live arms, For other makes of tonearm – Origin Live Aurora Gold Platter Driven User Manual

Page 4

Page 4

F I T T H E T O N E A R M

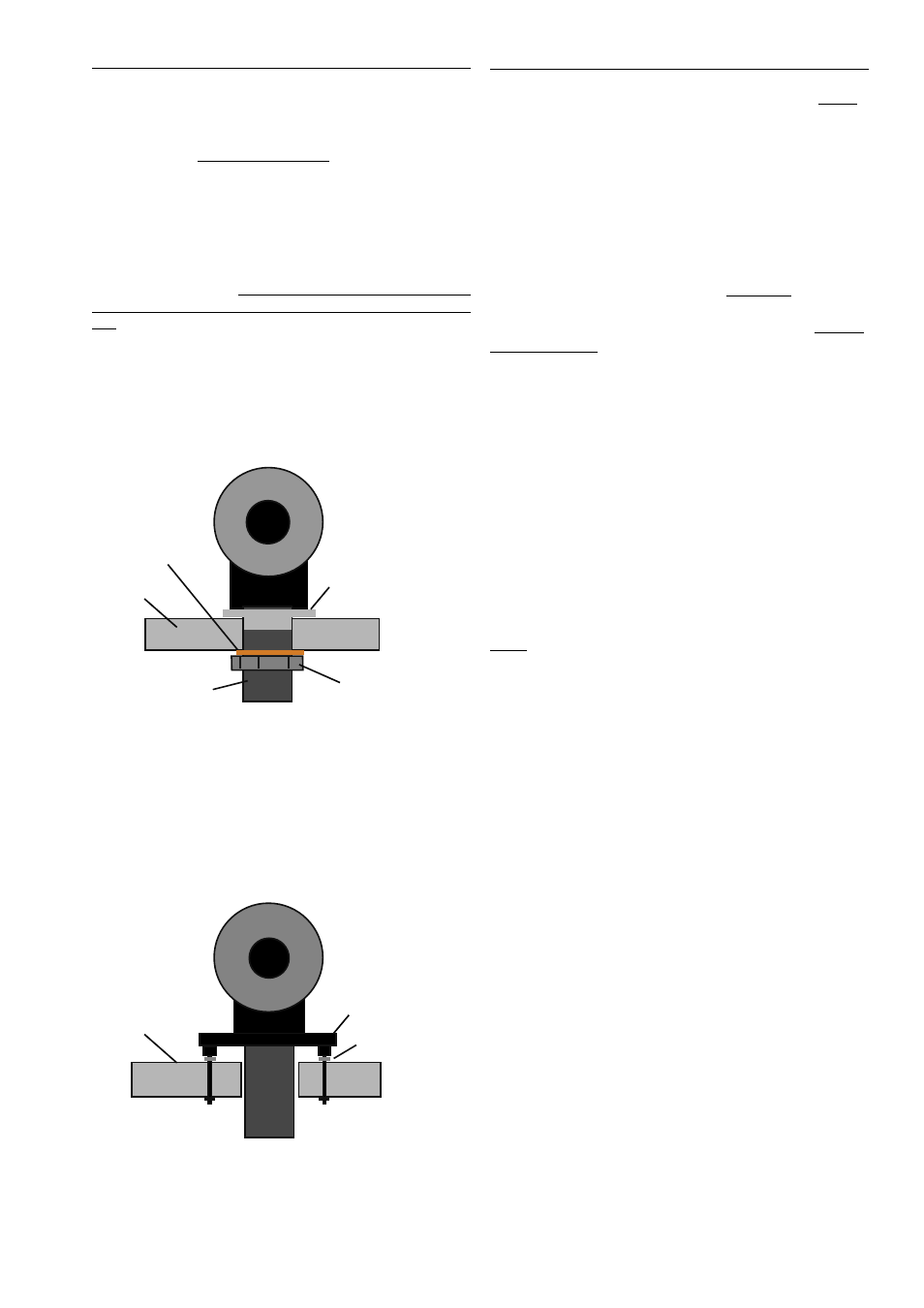

Mounting Origin Live arms

Thread the threaded vta adjuster onto your arm if it is an Origin Live

Encounter or above. If your deck is a Sovereign and you have an Encounter

arm or above - do not fit the threaded vta adjuster ( the exception to this

rule is when the Sovereign uses the heavyweight platter which should use

the threaded vta adjuster). The adjuster must be oriented such that the

largest diameter is uppermost. Insert your tonearm into the armboard hole

such that the vta adjuster locates centrally. Next fit the cork washer as shown

in the diagram below before threading on the large clamping nut. You can

set the arm to the correct height later but for now just clamp the arm in

position using the large nut. To adjust the height of the arm, screw the vta

adjuster up or down and reclamp the arm using the large base clamping

nut.

NOTE - For Origin Live arms with integral vta adjuster i.e Encounter

and above you should raise the arm height to just below the right level

using the threaded vta adjuster and then use the arm vta wheel for fine

adjustment.

A R M

REAR VIEW OF ARM ON ORIGIN LIVE DECK WITH

THREADED VTA AND CORK WASHER

ARM MOUNT

SURFACE

CORK WASHER

LARGE CLAMPING NUT

THREADED ARM BASE

THREADED

VTA ADJUSTER

If you have the OL1 or Rega arm with 3 hole

mounting

The arm is bolted or screwed to the deck using the 3 mounting holes in the

base of the arm. To raise the arm for VTA adjustment you will need to fit

3 or more spacing washers under the arm base holes. One peice spacers are

available from Rega if you want a neater looking solution.

3 POINT ARM MOUNTING

Sub-chassis or

armboard

3 off bolts or

wood screws

Spacers

For other makes of tonearm

Origin Live can provide the correct cut out in the sub-chassis or armboard

for other makes of arm and after this refer to your arm installation

instructions.

F I T T H E P L A T T E R

NOTE - On newer decks (April 2009 onwards) the platter is a “loose” fit

over a metal bush on the spindle. This means the platter can be removed

from the spindle. TIP - Once the platter is fitted over the bush it pays to

spin it slowly by hand while holding the top of the spindle stationary with

your other hand - this helps the platter to “bed down” onto the bush and

become more level.

Oil the bearing - with the small oil bottle supplied, run approx 10 drops of

oil into the top of the bearing house.

Insert the spindle - Wipe the platter spindle surface first

to ensure that it is absolutely clean and very gently insert it

into the bearing house (If the oil does not overflow when the

spindle touches the bottom then try 2 drops at a time till you

achieve overflow - wipe away excess oil without withdrawing

the spindle. Ideally you should spin the spindle slowly as it

settles into the bearing to ensure distribution of oil.

When you oil the bearing you can get a false impression of

overflow if the spindle has oil on it - the oil simply scrapes off

as the bearing goes in and ends up on the top of the bearing

house. You can “feel” overflow when inserting the spindle, it

meets resistance at the bottom which is not a “thud” of the

spindle hitting the bottom but rather a build up of pressure

of the bearing landing on a bed of oil. By further pressing,

you can then see the oil being squeezed out at the top. Lastly,

if applicable, carefully lower the platter over the spindle till it

rests on the lower flange of the platter bush (ensure mating

surfaces are clean).

gently insert the platter spindle into the bearing house (If the

oil does not overflow when the spindle touches the bottom

then try 2 drops at a time till you just achieve overflow - wipe

away

N O T E :

The bearing needs a few minutes to “run in” and should run

silent when truly vertical and full of oil

- if it doesn’t do so,

there has probably been contamination with dust and you

will need to clean it out with a lint free paper towel or similar

wrapped around a thin rod. If you do this, be sure to also wipe

the oil off the spindle as this also may contain microscopic

contamination that is not visible.

Fit the belt over the motor pulley and platter.

Set the belt tension by positioning the motor housing relative to the

turntable. Ideally the centre of the pulley should be approximately 225mm

from the centre of the bearing house.

Note: It is very common for people to set the belt tension too

tight, which can slightly degrade performance. The optimum

setting is where there is enough tension to turn the platter

without audible wow and flutter but no more. This may take

some experimentation.

It also aids performance to clean all the running surfaces with

mentholated or surgical spirit.

Ensure that the motor pod is not touching any other plates on

the deck.