Turntable set up – Origin Live Aurora Gold Platter Driven User Manual

Page 3

Page 3

Turntable set up

When you unpack the deck, check that you have all the items listed in the

parts list.

S E T T I N G U P T H E P L I N T H

Place the motor pod in position at the rear of the plinth. The motor pod

should be located approx 2mm away from the edge of the plinth outer ring.

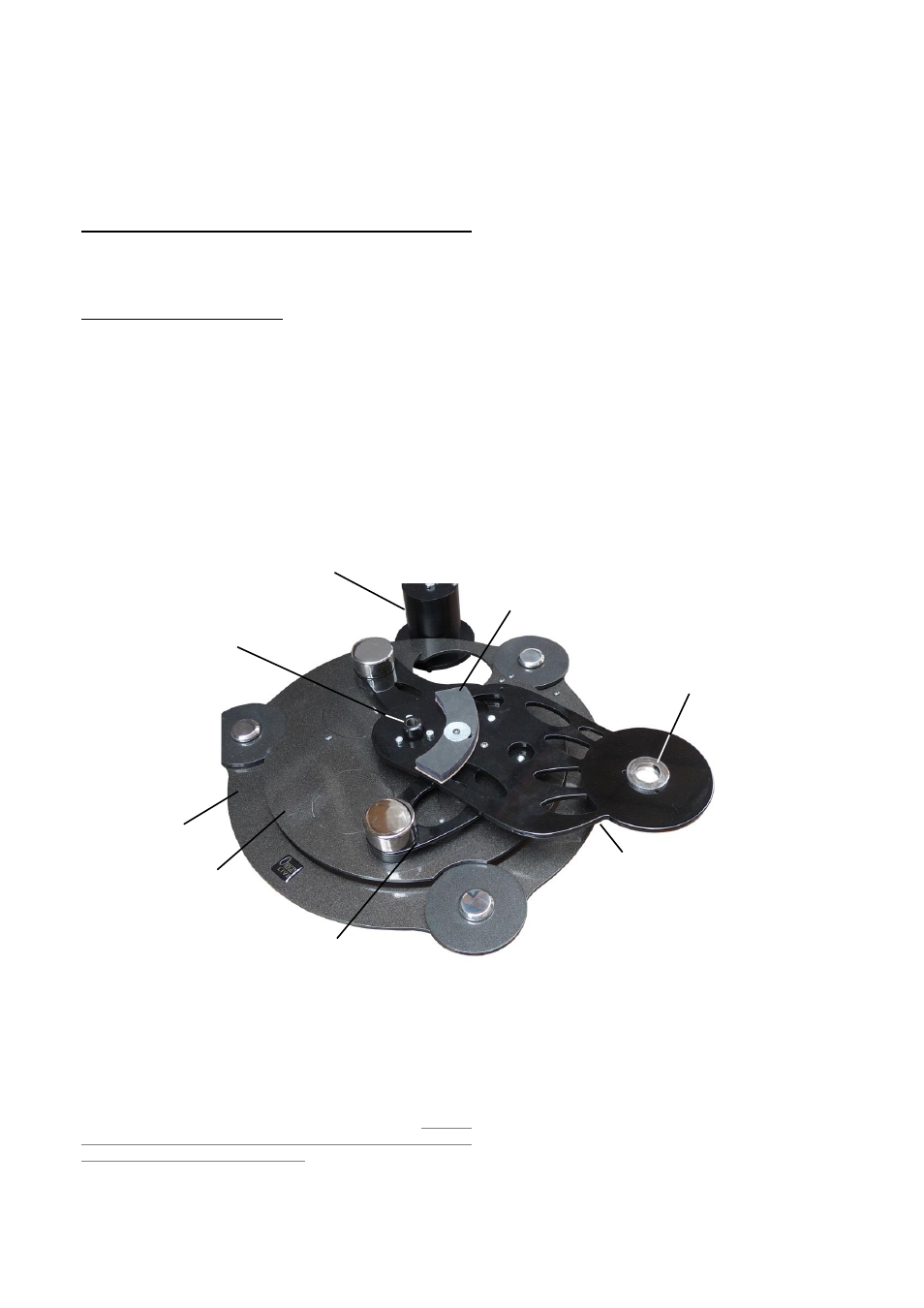

Place the sub-chassis on the plinth as shown in the photo. The small

locating pins on the underside of the two black pods locate in the small holes

on the plinth. DO NOT TIGHTEN THE BOLTS IN THE PODS - they

are set to be loose deliberately - if they are tightened sound degradation will

result.

You will find that the sub-chassis can rotate very slightly on the plinth – rotate

it so that the bearing moves towards the motor pod.

Photo showing sub-chassis & part names

VTA threaded height adjuster -

use on arms with threaded base

- turn clockwise to raise the arm

SUB-CHASSIS placed on plinth such that pod pins

locate in plinth holes

MOTOR POD placed approx so

that a gap of approx 2mm exists

between pod tube and edge of

plinth outer ring

CURVED DAMPER

SUB-CHASSIS PLATE

BOTTOM SUB-CHASSIS PLATE

BEARING HOUSE

PLINTH OUTER RING

PLINTH INNER PLATE

NOTES:

Trouble shooting notes on the sub-chassis (optional reading)

1. The sub-chassis is attached to the “bottom sub-chassis platee” by one “pivot

bolt” – the two plates should be free to swivel and are loosely restrained by an

“anti-rotate bolt” – this locating bolt on the side of the sub-chassis should be

left alone. The pivot bolt is tightened at factory and should not be tightened

or the performance will degrade significantly.

2. If this setting is lost for any reason then the correct tension is such that

the bottom sub-chassis plate can rotate minutely but freely in relation to the

subchassis plate but has minimal “rocking” motion in the vertical plane.

3. The “anti rotate” bolt is bolted tightly to the bottom sub-chassis plate but

has minimal contact with the sub-chassis.

4. If for any reason, tension is lost on any of the other bolts then they should

be just “nipped” tight by 1/8 of a turn from the point where you can just turn

the bolt & nut freely in it’s hole – any tighter than this and performance is

degraded.