ISSPRO R82511 User Manual

Page 2

Form No. IS157 (Rev. B 05/06/2008

)

ISSPRO, INC.

2515 N.E. Riverside Way

Post Office Box 11177

Portland, Oregon 97211-1899

503-288-4488

800-888-8065

Fax: 503-249-2999

www.isspro.com

© 2008 ISSPRO, Inc. All Rights Reserved.

4

Find a location where exhaust backpressure can be measured without the sensor exceeding 275° F.

This typically requires at least a 12” length of metal tubing (typically 3/16” or larger copper) connected

to a tapped hole in the exhaust manifold, with the sensor installed in the other end of the tubing. If a

factory Exhaust Backpressure sensor is used, you may be able to install a Tee fitting (obtain from your

local automotive supply store) to accommodate this sensor in the same location.

5

Install the new sensor. Pressure sensor threads are ⅛” NPTF.

Many Emission Control Devices are connected to temperature sensors or switches. Be careful not

to disable these when installing a sensor.

6

If leakage occurs at the sensor, tighten one-quarter turn at a time until leakage stops. If necessary,

thread sealant such as Teflon tape may be used.

When using a torque wrench, tighten approximately 20nm/15 lb-in. or slightly more, if leakage

occurs. Do not use the body of the sensor to tighten! Use only the hex and the correct wrench. Do

not over tighten!

7

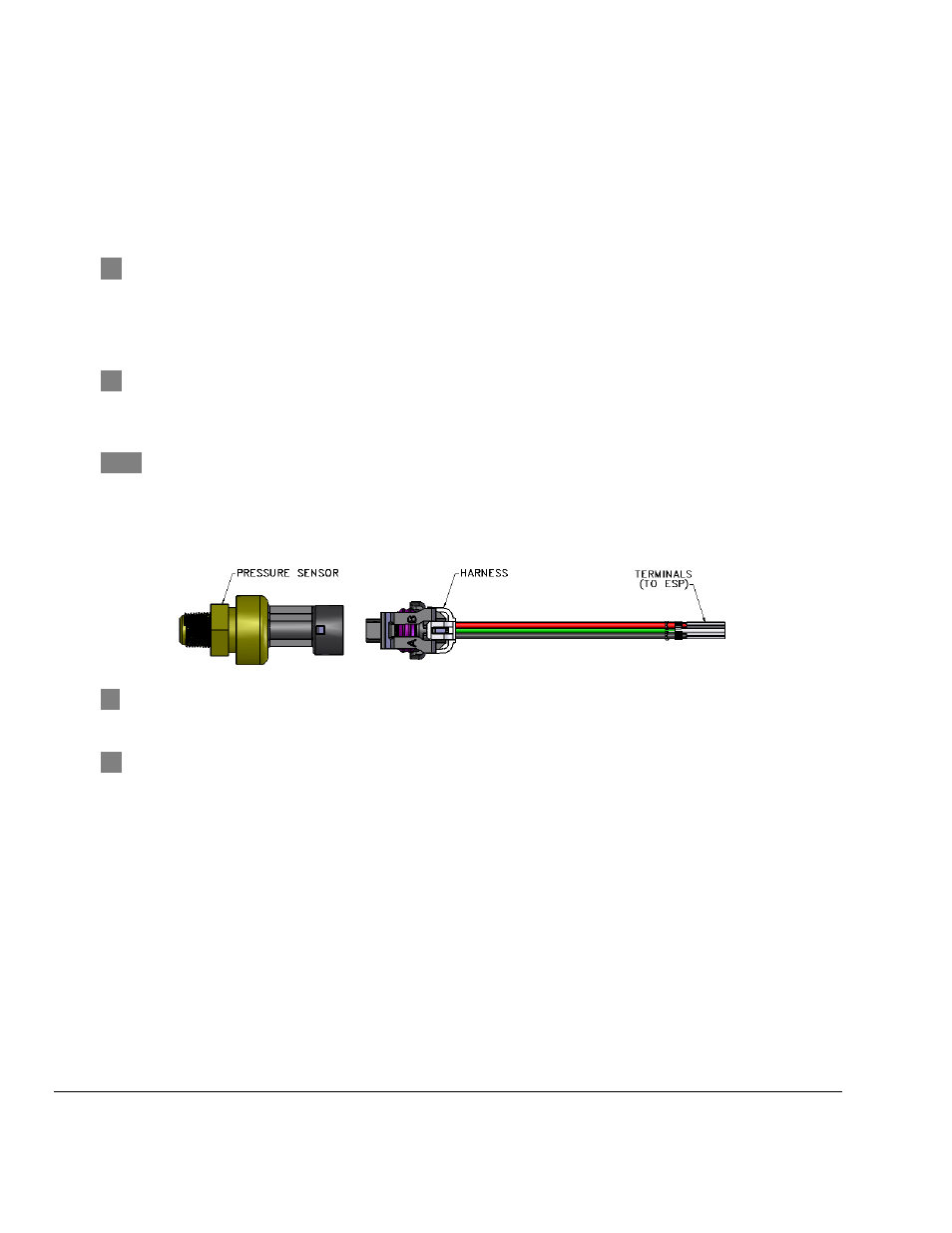

Connect the pressure sensor to the pressure sensor harness by pressing the connector into the

slot.

Figure

3: Pressure sensor and harness.

8

Connect pressure gauge to the ESP. (See ESP instructions for more details on how to do this).

Note: If drilling a mounting hole in a panel to mount this gauge, the hole size should be 2.040”.

9

Secure all wiring so that it does not interfere with moving parts or chafe on sharp edges. This may

be accomplished by routing the wiring within the factory wire harness sheath, using wire ties and

sheathing, and using appropriate grommets when passing through the firewall.