ISSPRO R18333 User Manual

ISSPRO Sensors

Form No. IS172 (Rev. G 11/21/2013)

ISSPRO, INC.

•

2515 N.E. Riverside Way

•

Post Office Box 11177

•

Portland, Oregon 97211-1899

503-528-3400

•

800-888-8065

•

Fax: 503-528-3495

www.isspro.com

© 2008 ISSPRO, Inc. All Rights Reserved.

TURBO BOOST PRESSURE GAUGE AND

SENSOR INSTALLATION INSTRUCTIONS

I C O N K E Y

CAUTION

Tools may be required

Shown in picture

1

Disconnect batteries. Do not reconnect battery power until system

is fully configured to avoid risk of shock or fire.

2

Find a location where boost pressure can be measured such as an existing

port on the intake, or cut the MAP (Manifold Absolute Pressure) line and

insert a Tee fitting (obtain from your local automotive supply store). If

there is an M8 x 1.25 intake bolt exposed to intake pressure, it can be

replaced with R7741, a hollow boost bolt for 1998.5 - 2006 Dodge models.

Alternatively, drill and tap the intake elbow for ⅛” NPTF.

3

Install the new sensor. Pressure sensor threads are ⅛” NPTF.

Many Emission Control Devices are connected to OEM sensors or switches. Be careful not to

disable these when installing a sensor.

4

If leakage occurs at the sensor, tighten one-quarter turn at a time until leakage stops. If necessary,

thread sealant such as Teflon tape may be used.

When using a torque wrench, tighten approximately 20nm/15 lb-in. or slightly more, if leakage

occurs. Do not use the body of the sensor to tighten! Use only the hex and the correct wrench.

Do not over tighten!

5

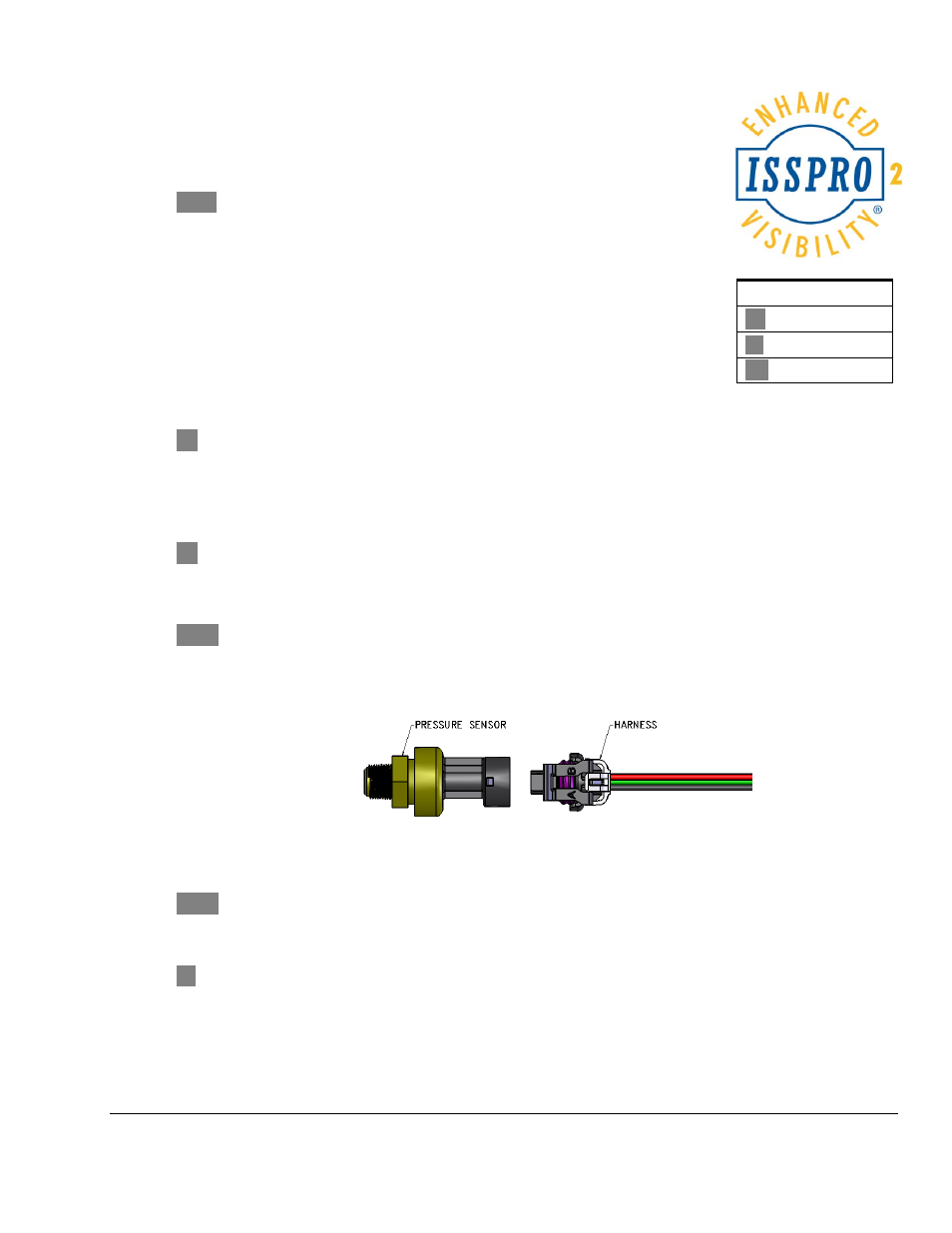

Connect the pressure sensor to the pressure sensor harness by pressing the connector into

the slot.

Figure 1: Pressure sensor and harness.

6

Route the sensor harness to the intended gauge mounting location, using grommets as appropriate

when passing through the firewall. Connect the sensor harness to the gauge connector as follows:

7

Trim wires to desired length. The red/yellow, green, and black wires are the +5V, sensor,

and ground connection, and connect to cavities 4, 5, and 6 of the orange connector respectively (see

Figure 2).

Install the three wires into the insulation displacement connector (orange connector). Carefully

lay the wires across the connector cavities, hold the connector steady with a vice or pliers and press

the wires into each cavity with a small screwdriver. Each wire must be pushed completely to the

bottom of its groove in the connector, to ensure a good electrical connection. Note that the 3

sensor harness wires run only between the gauge and the sensor, not connecting to any other power

or ground.

- R18233 R17733 R17633 R17433 R17333 R17233 R17255 R17133 R16733 R16633 R16433 R16333 R16233 R16133 R15733 R15633 R15433 R15333 R15233 R15133 R14733 R14633 R14433 R14333 R14233 R14133 R13733 R13633 R13433 R13333 R13233 R13133 R12733 R12633 R12433 R12333 R12233 R12133 R11733 R11633 R11433 R11333 R11233 R11133