Vermont Casting 2490 User Manual

Page 27

27

Resolute Acclaim Woodburning Stove

2000893

Gaskets on Resolute Acclaim

Stationary Parts

5/16”

Between the flue collar and flue

collar extension and the stove’s top

and back:

5/16”

The seal between the upper fireback

corners and the lower fireback:

5/16”

The seal between the underside of the

top plate and the upper edge of the

upper fireback

5/16”

The damper plate to the reverse side of

upper fireback

5/16”

The seal between the sealing plates

and the vertical ribs of the

stove back

NOTE: When replacing this last gasket after removing

the upper fireback, place two (2) cap screws into the

upper fireback mounting holes before you cement the

channels and replace the gasket. The new gasket will

run inside the cap screws. Remove the screws after the

gasket cement dries.

Replacing the Door Gaskets

•

Lift off the door as described previously. Lay it face

down on a padded surface.

•

Follow steps 1-4 on gasket replacement as de-

scribed previously.

Replacing the Griddle Gasket

•

To replace either the damper or the griddle gasket,

follow Steps 1-4 on replacing gaskets described

previously.

Replace Broken Firebricks

If a firebrick breaks, replace only with Vermont Cast-

ings’ custom firebricks, available from your local dealer.

CFM Corporation custom firebricks contain metal rein-

forcements that maintain the brick’s integrity if it cracks.

A brick that is cracked but still intact does not need to

be replaced.

A Clean Chimney System ss Safer

and Works Better

Learn to Recognize Creosote and Soot

When you first begin using the stove, check daily for

creosote — a substance that can look like either thick

tar or black, crisp flakes. Experience will show how

often you need to clean to be safe. The frequency

may even vary during the year. In the colder months

when the hottest fires producing the least creosote are

burned, you may need to clean less frequently. Dur-

ing the warmer months when creosote is more likely to

result from cooler-burning fires and weaker draft, more

frequent cleaning may be necessary.

At the very least, inspect the chimney and chimney

connector twice monthly. Clean if necessary. Let the

stove cool to check if a buildup of creosote or soot has

occurred. If a significant layer of creosote has accu-

mulated—1/8” (3mm) or more—it should be removed

to reduce the risk of a chimney fire. Failure to keep the

chimney and connector system clean can result in a

serious chimney fire.

The conditions for a chimney fire develop like this:

When wood is burned slowly, it produces tar and other

organic vapors, which combine with expelled moisture

to form creosote. The creosote vapors condense in the

relatively cool chimney flue of a slow-burning fire. As a

result, creosote residue accumulates on the flue lining.

ST626

Res Acclaim

door gasket

10/1/02 djt

Stove front to door:

1/2” gasket

Grate to stove

front: 1/2” gasket

Glass to door frame:

3/16” gasket

ST626

Fig. 39 Two different gasekt sizes are used to seal the front

door.

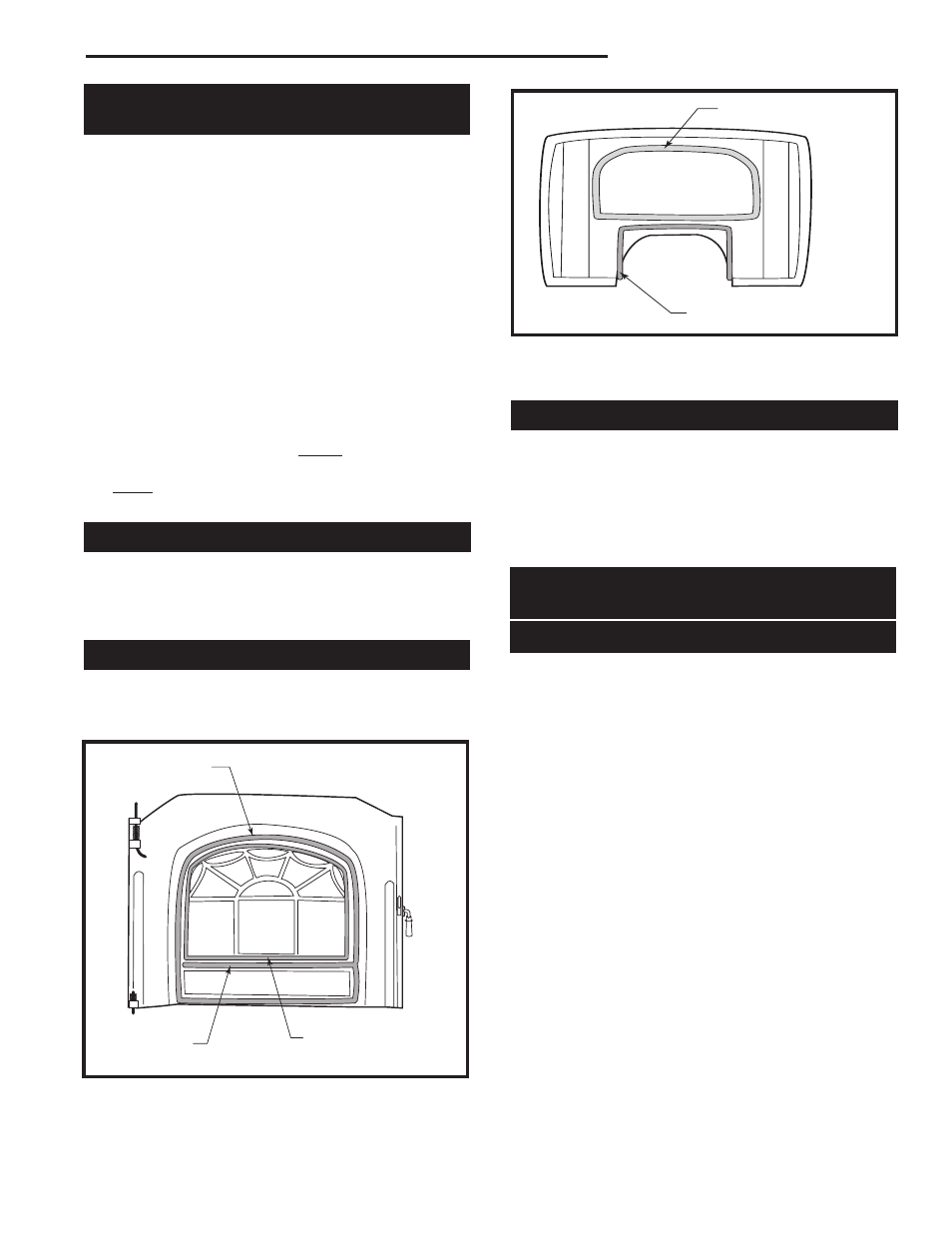

ST627

griddle gasket

2/6/01

5/16” Wire Mesh Gasket

5/16” Fiberglass Gasket

ST627

Fig. 40

A 5/16” wire mesh gasket seals the griddle to the

stove top. The flue collar is sealed with a 5/16” fiberglass

gasket.