Set-up and installation for all 1” valves, Set-up and installation for 11/2” valves, Ews, inc. / environmental water systems – Environmental Water Systems TT 1054 TWIN TANK User Manual

Page 4

EWS, Inc. / Environmental Water Systems

www.EWSWATER.com

4.3-4

PLUMB INLET

(supply)

AND OUTLET

(filtered)

INTO UNIT AND PLUMB BYPASS VALVE BETWEEN.

•

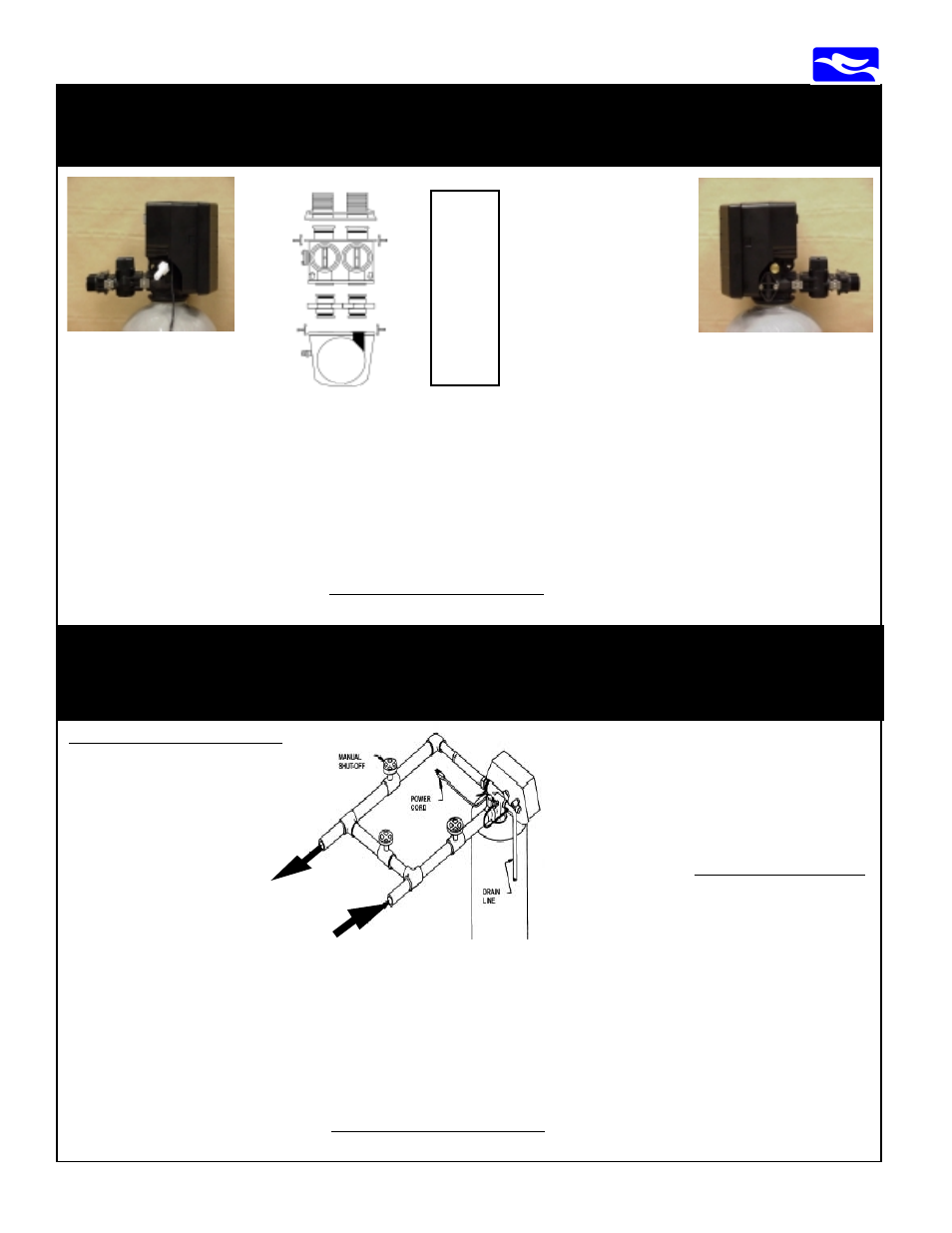

Follow the directional arrows molded onto the valve body. See picture below for correct set-up.

•

Use unions (a quick disconnect feature) at the inlet and outlet pipe, as pictured, to allow future servicing of

system without cutting and replumbing

•

Use Ball Valves (preferred - easy to turn on/off) at inlet/outlet pipes and bypass, as pictured for proper installa-

tion.

•

NO Heat, No Torch; Leave at least 12” between the valve body and any solder joints. Solder joints prior to

connecting to valve body. Failure to do this could cause interior damage. Teflon tape is the only sealant to used

on any of our fittings.

WARNING:

ONCE PLUMBED, DO NOT TURN ON WATER, UNTIL YOU BEGIN START-UP

PROCEDURES.

Inlet (supply) Side

Outlet (filtered)

Side

Bypass

Valve

Drain

Electric

11/2” 2850 Valve

Valve Cover: Black

NEMA 1 Rated

for resistence to

dust and moisture.

Hinged: left

Opens: from right

Controls: inside

DO NOT TURN ON WATER,

OPEN ANY VALVES OR

PLUG IN THE ELECTRICAL

UNTIL YOU GO TO THE

START-UP PROCEDURES

Back Side:

Front Side:

Drain:

1” MNPT

Connected (included) to:

Brass Flow Control

Housing with 10 GPM

Flow Restrictor

1” FNPT x 3/4” FNPT

Materials Needed for Drain:

3/4” copper x male adapter

3/4” union

3/4” (min) drain line

length to be determined

Materials Needed for Installation:

11/2” pipe length to be

determined

3 - 11/2” Ball Valves

2 - 11/2” Unions

See Drain Requirements

Union

Union

inlet

side:

supply

from

main

right

top view:

outlet

side:

to the

home

filtered

left

front:

Inlet (supply) Side:

right side view of valve and

brine line with included

bypass and male yoke

USING THE CONNECTED BYPASS VALVE AND 1” MALE NPT YOKE.

PLUMB INLET (supply) AND OUTLET (filtered) INTO THE UNIT.

•

Follow the directional arrows molded onto the valve body and bypass. See pictures below for; top/front/back

and left/right views to prevent plumbing the unit backwards. Teflon tape is the only sealant to used on any of our

fittings. WARNING: No pipe dope.

•

NO Heat, No Torch; Leave at least 12” between the male yoke and any solder joints. Failure to do this could

cause interior damage. Consider flexible stainless (1”FNPT x 1”FNPT (3/4” if your application) and at least 18”

in length) connected to copper male adapters, or some other applicable connection - no heat, saves time, neat

install, if applicable/code to your application.

WARNING:

ONCE PLUMBED, DO NOT TURN ON WATER, UNTIL YOU BEGIN START-UP

PROCEDURES.

Outlet (filtered) Side:

left side view of valve and drain

port with included drain adaptor,

bypass and male yoke

Must use dual-port, full

flow, noryl bypass with

1” MNPT yoke.

•

Shuts off water to/from

the unit

•

No additional plumbing

for media replacement or

maintenance

•

Less costly plumbing

installation, easier start-

ups, non-corrosive

Yoke

1” MNPT

Dual

Port

Bypass

O-Ring

Connect

Valve

Head

back:

Set-Up and Installation for All 1” Valves:

RT 935, RT 1035, TT 1054

Set-Up and Installation for 11/2” Valves:

TT 1354-11/2