Dynojet 248: Maintenance Guide User Manual

Page 9

A U T O D Y N O M A I N T E N A N C E

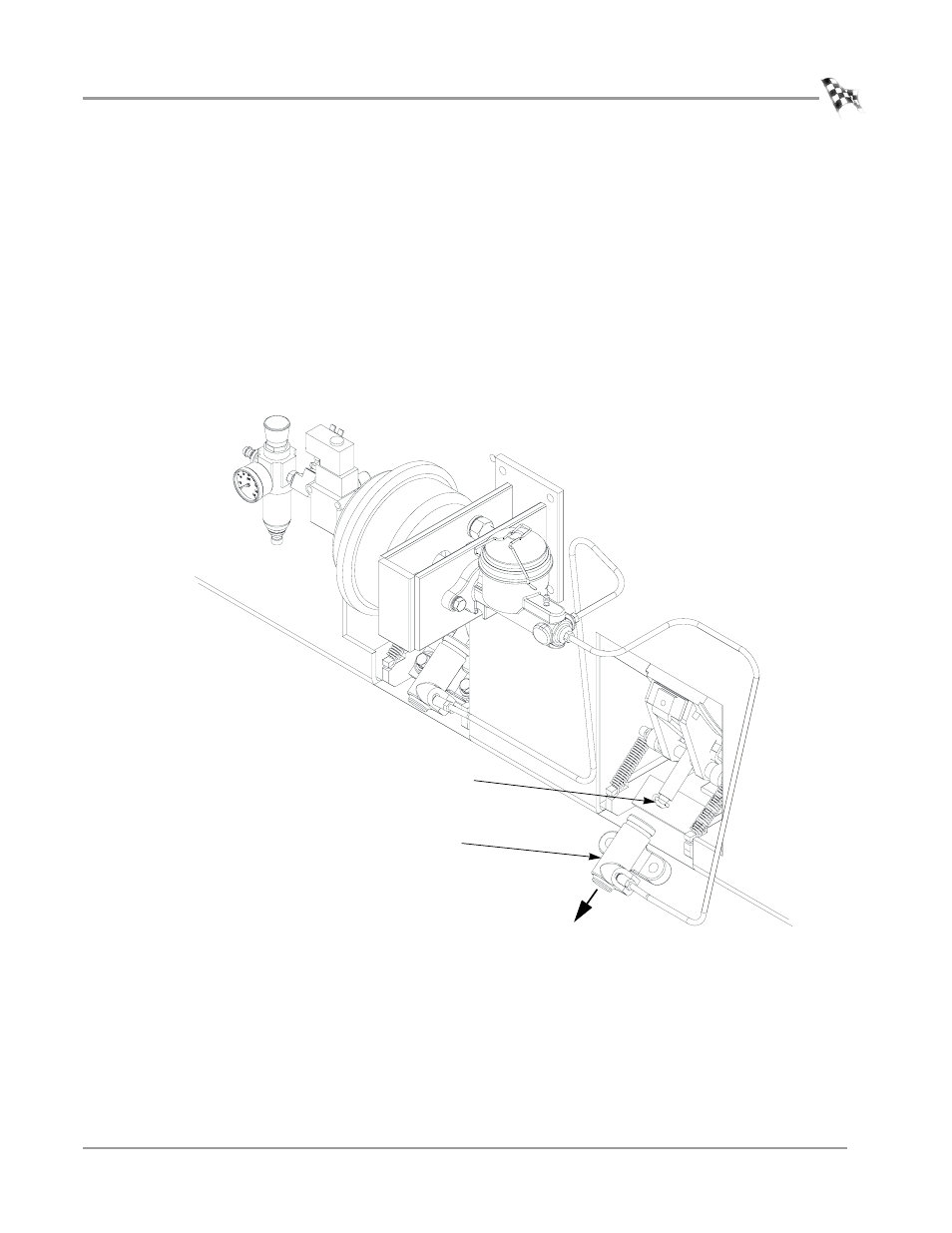

Model 224 Dynos with Air Over HyDraulic (AOH) Brake Systems

Version 3

Maintenance Guide for Automotive Dynamometers

5

4b

Pull the slave cylinder away from the dyno being careful not to kink the

brake line.

4c

Screw the brake piston rod in to increase brake shoe clearance or out to

decrease brake shoe clearance. Refer to Figure 3.

4d

Attach the slave cylinder using the bolts and washers removed earlier.

4e

Recheck the brake shoe clearance. No part of the brake shoe should touch

the drum.

Note: If you cannot adjust the brakes to specification, you will need new brake

shoes. Contact Dynojet.

5

Turn on or reconnect the air supply and verify the drum brakes operate before

replacing the covers and using the dyno.

Figure 3: 224 Dyno AOH Brake—Pull the Cylinder Away

AD205

carefully pull slave

cylinder away to expose

the brake piston rod

screw brake piston rod

in or out to adjust brake

clearance