Warning – Code 3 OsciLaser Flushmount User Manual

Page 3

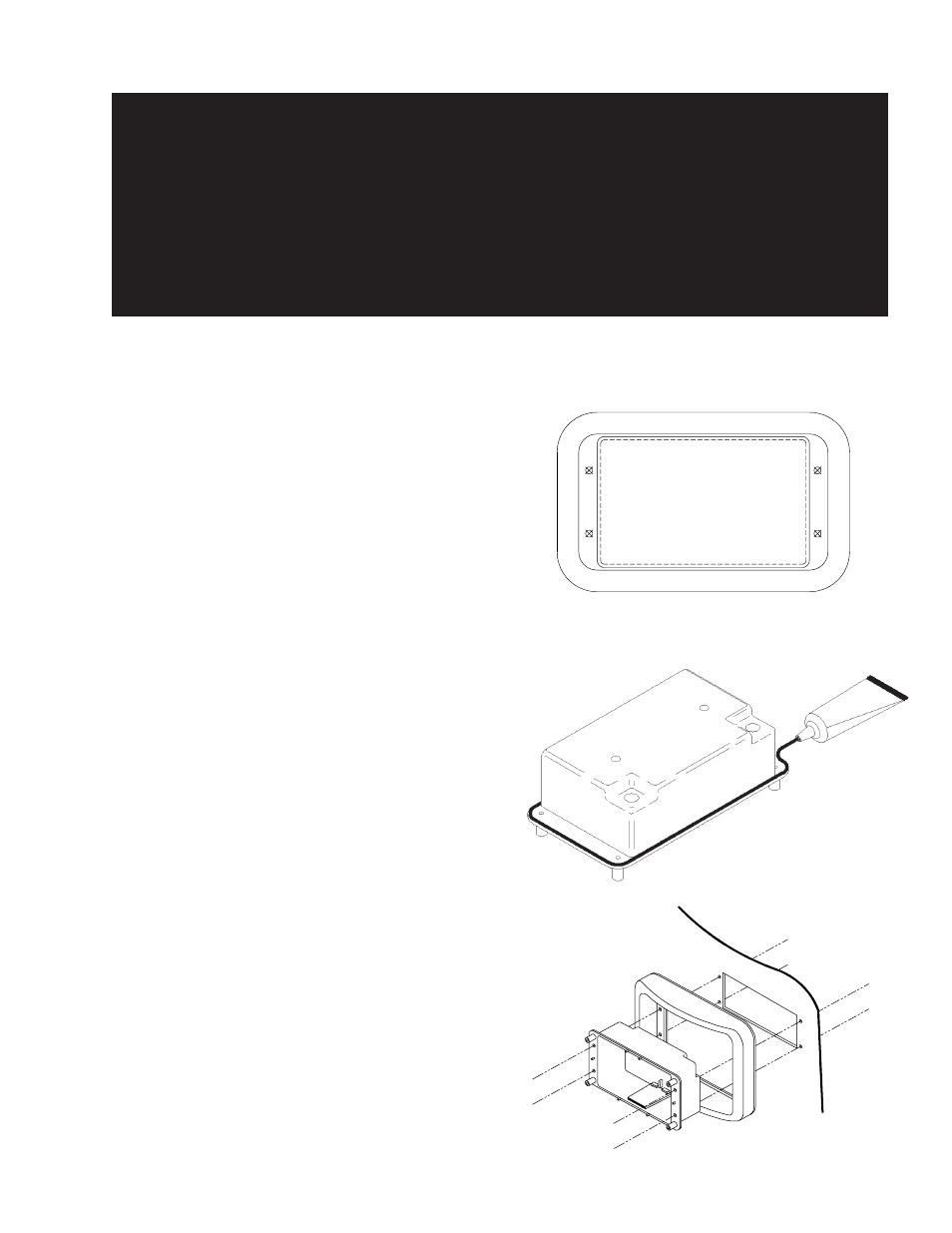

FIGURE 1

FIGURE 2

NOTE: All of the information listed in this booklet must be

given to the end user by the installer.

1) Using the trim bezel as a template, inscribe the position

for mounting the OsciLaser

TM

as shown in Figure 1. To

access and mark mounting holes, the gasket must be

pierced with an ice pick or a sharp pointed object. Be

sure to mark positions for the four mounting holes when

completing this task.

2) At these inscribed positions, first drill the holes for the

mounting screws using 3/16" drill bit. If it is not possible

to access the product from behind the surface being

mounted, a 1/8" drill bit should be used for the sheet

metal screws also included in the mounting kit. Once

this is accomplished, cut the rectangular hole for the

housing.

3) Using

GE Silicone II or a sealant with equal properties,

lay a small bead around the housing as shown in Figure

2. This bead must be placed on the outer edge of the

housing to ensure a proper and effective seal.

4) Slide the housing into the trim bezel and through to the

hole on the vehicle as illustrated in Figure 3. Make sure

the housing is oriented properly with the drain hole on the

bottom and the two wiring holes at the top.

5) Once the housing and bezel are positioned in the hole,

use the four #8 x 1-1/2" stainless steel machine screws,

nuts, washers and lockwashers to secure the assembly

to the vehicle (Figure 4). At this point, make sure that any

excess sealant is wiped clean from the assembly. As

noted in step 2, if accesss to the back of the mounting

surface is not possible, it will then be necessary to use

the four #8 x 1-1/4" stainless steel, sheet metal screws

provided. In this situation, steps 6 through 8 must be

competed before the bezel/housing assembly is affixed

to the vehicle.

FIGURE 3

Particular attention should be paid to the location and method of making electrical

connections and splices to protect these points from corrosion and loss of conductivity.

Ground terminations should only be made to substantial chassis components, preferably

directly to the vehicle battery. The user should install a fuse sized to approximately 125% of the

maximum Amp capacity in the supply line to protect against short circuits. For example, a 30

Amp fuse should carry a maximum of 24 Amps. DO NOT USE 1/4" DIAMETER GLASS

FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES ABOVE 15

AMPS. Circuit breakers are very sensitive to high temperatures and will "false trip" when

mounted in hot environments or operated close to their capacity.

WARNING!

3