Unpacking & pre-installation, Installation & mounting, Warning – Code 3 Code 360 User Manual

Page 4: Hook-on mounting

4

Unpacking & Pre-installation

Carefully remove the light bar and place it on a flat surface, taking care not to scratch the lenses or damage the cable coming out of the

bottom. Examine the unit for transit damage, broken lamps, etc. Report any damage to the carrier and keep the shipping carton.

Standard light bars are built to operate on 12 volt D.C. negative ground (earth) vehicles. If you have an electrical system other than 12

volt D.C. negative ground (earth), and have not ordered a specially wired light bar, contact the factory for instructions.

Test the unit before installation. To test, touch the black wire to a negative ground (earth) and the other wires to +12 volts D.C., in

accordance with the instructions attached to the cable (an automotive battery is preferable for this test). A battery charger may be used, but

please note that some electronic options (flashers, stingrays, etc.) may not operate normally when powered by a battery charger. If

problems occur at this point, contact the factory.

Installation & Mounting

MOUNTING HARDWARE - All mounting hardware is packed in a small box inside the main carton. Four standard kits are available: (1)

Hook-On Type, (1) Tow and Recovery and (2) Permanent Types. These are discussed in detail later. Note: Hook-on mounting for

"gutterless" type vehicles will require a special hook for mounting. Several special application hooks are available. Contact the factory for

details.

Utilizing non-factory supplied screws and/or mounting brackets and/or the improper number of

screws may result in loss of warranty coverage on the equipment.

WARNING!

!

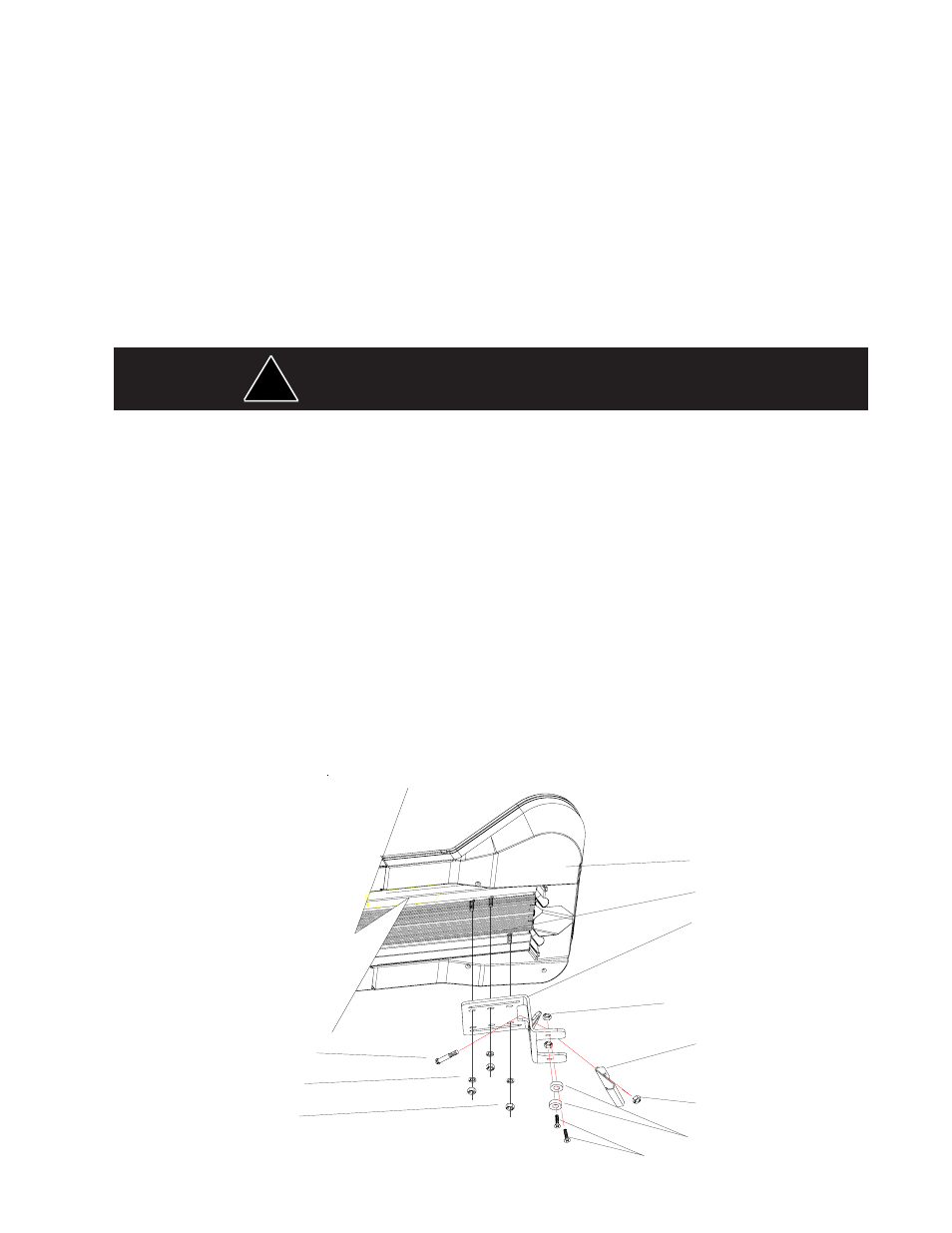

Mounting Bracket

Bottom of Lightbar

5/16" Split Lockwasher

Rubber Feet

5/16" Nut

FIGURE 1

Hook-on Mounting

Begin the installation by attaching the rubber feet to the mounting brackets with 3/8" long Flat Head Screw and Nylock nuts. See

Figure1. Place the light bar upside down on a table or other work surface, being careful not to scratch the lenses. Slide the 5/16"

carriage bolts into the frame. Secure the mounting brackets finger tight so they support the weight of the light bar, but still are

positionable. Now would be a good time to insert the 3 1/2" long carriage bolt through the mounting brackets. If desired, you can also

unbundle the lightbar cable and feed it through the drivers' side mounting bracket. Locate the vehicle on a level surface. Place the

lightbar on the roof of the vehicle. Place a soft pad in the center of the roof to protect the paint. The mounting brackets must be placed

so that the rubber feet are resting on the curved section of the roof, see Figure 2. This is the strongest part of the roof. If necessary

bend the mounting bracket feet to match the contour of roof. Once the light bar is centered, tighten the mounting bracket to the light bar.

Using a tape measure and a level, center the light bar from side to side and locate a position on the roof where the light bar is level.

Black nylon spacers are provided to level lightbar. Place spacer between rubber foot and mounting bracket and use longer flat head

screws provided to secure foot to bracket.

Gutter Hook

5/16" x 3 1/2"lg Carriage Bolt

5/16-18 Carriage Bolt

5/16" Nylock Nut

Nylock Nut

Flat Head Screw