Code 3 87, 88, 89 Series Perimeter Lights User Manual

Page 4

INTERIOR WALL OF VEHICLE OR

NEAREST OBSTACLE DIRECTLY BEHIND

LIGHT HEAD

2.000 MINIMUM

EXTERIOR WALL OF VEHICLE

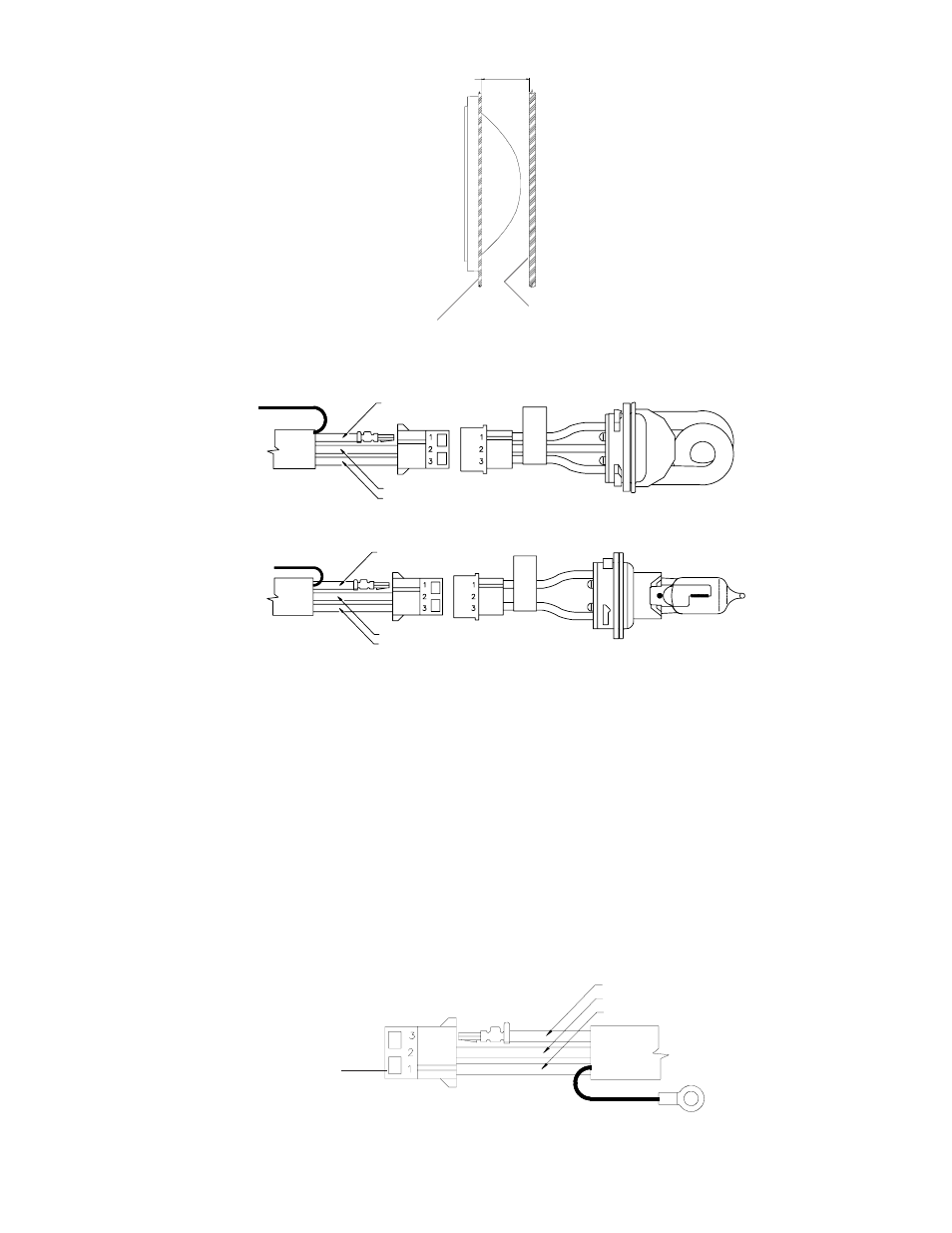

FIGURE 2

FIGURE 3

1.

Select the desired mounting location for the light head assembly.

2.

Verify 2 inches minimum free clearance behind the mounting surface, see Figure 2.

3.

Cut the opening and drill the holes, use Figure 1 template or the trim bezel if your light head is so equipped.

4.

With one end of the cable at the light head mounting location, route the three wire cable to the Power

Supply.

5.

At the light head end of the cable, insert the 3 AMP sockets into the AMP socket housing as shown in Figure

3. Cut the shield wire flush with the jacket. (Halogen Lamp Assemblies are shown. Procedure is the same

for Strobe Lamp Assembly.)

6.

Allow 3 inches minimum slack at the light head to facilitate lamp assembly replacement. Secure the cable.

7.

At the power source end of the cable determine if the cable length is acceptable. If a shorter length is

required, coil the cable and tie with an electrical tie.

8.

Insert the 3 AMP sockets into the AMP socket housing as shown in Figure 4.

9.

Crimp the #8 ring terminal to the shield wire and attach to nearest grounded structure.

RED WIRE - HIGH VOLTAGE

BLACK WIRE - GROUND (EARTH)

SHIELD WIRE

(CUT FLUSH)

FIGURE 4

BLACK WIRE - GROUND (EARTH)

THIS END TO POWER

SUPPLY

SHIELD WIRE (Not used on

Model 88.)

RED WIRE - HIGH VOLTAGE

(STROBE)

12/24 VDC (HALOGEN)

WHITE WIRE - TRIGGER

WHITE WIRE - TRIGGER

SHIELD WIRE

(CUT FLUSH)

RED WIRE - +12/24 VDC

BLACK WIRE - (NOT USED)

WHITE WIRE - GROUND(EARTH)

4