Assembly – Craftsman 113.244513 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

assembly

NOTE:

The upper and lower blade guides support

the blade and keep it from twisting during opera

tion. An adjustment is necessary when blades

are changed, replaced or installed for the first

time.

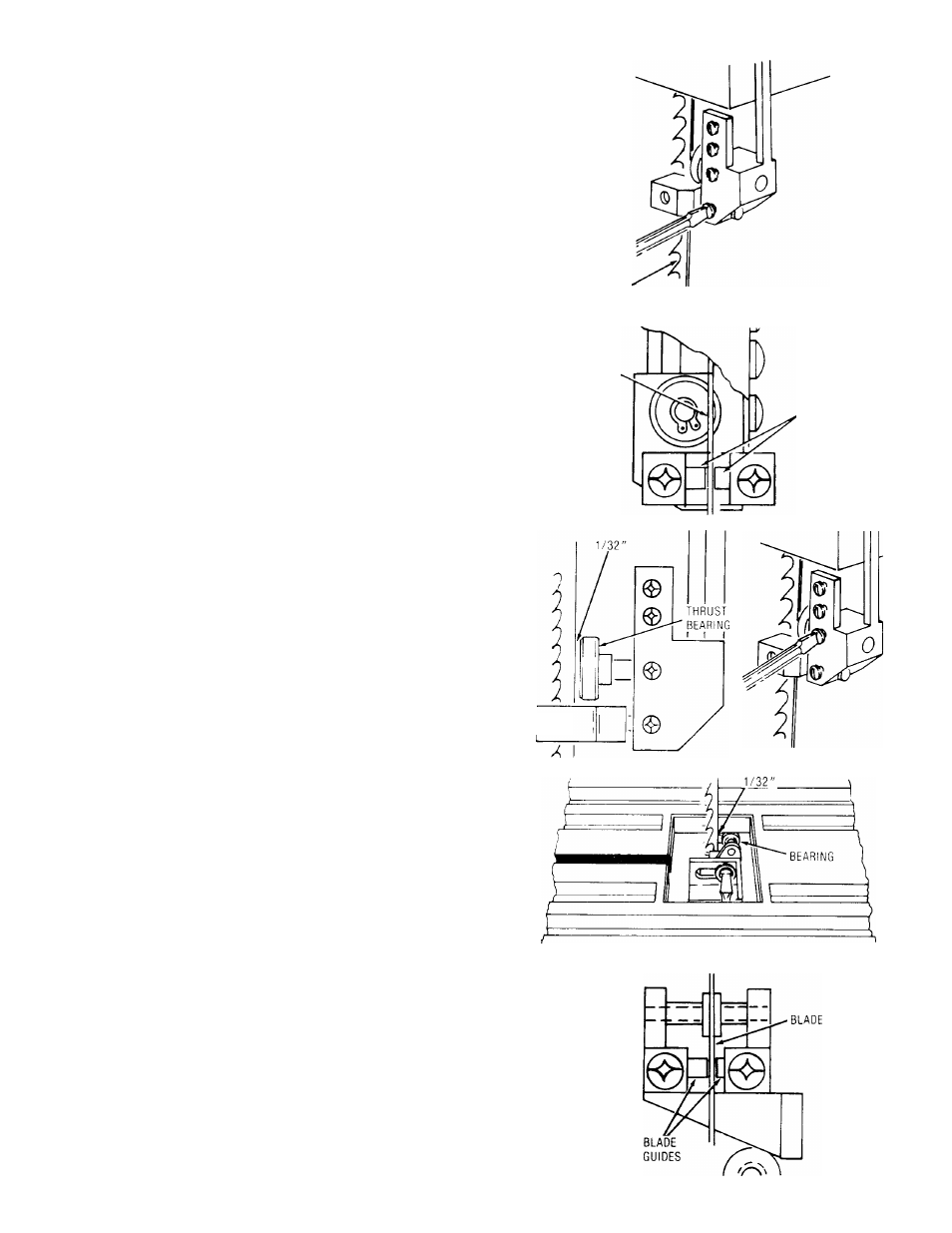

ADJUSTING UPPER BLADE GUIDE ASSEMBLY

1.

Loosen lower screw on side of upper blade

guide assembly and slide assembly forward

until the front edge of the blade guides are

approximately 1/32" from the GULLET of the

saw blade. Tighten screw.

GULLET

ADJUSTING UPPER BLADE GUIDES

1.

Loosen the two screws that lock the upper

blade guides and press the two guides evenly

against the sides of the blade but do not

pinch the blade. Release the guides and ro

tate the upper wheel slightly clockwise mov

ing the blade downward. Make sure one

guide is not further away from the blade than

the other. Tighten both screws.

SAW

BLADE

SLADE

GUIDES

ADJUSTING UPPER THRUST BEARING

NOTE:

The thrust bearing supports the

blade

from the rear and will rotate when the blade

is

pushed against it while you are cutting.

As soon

as you stop cutting, the bearing should

stop

rotating.

1.

To adjust, loosen the upper screw on

the side

of the upper blade guide assembly and

slide

the bearing forward until it is approximately

1/32" from the back of the blade.

Tighten

screw. Rotate upper wheel slightly clockwise

to check clearance. Readjust if necessary.

® o

ADJUSTING LOWER BLADE GUIDE ASSEMBLY

1.

Loosen the screw (as shown) on the side of

the lower blade guide assembly and slide

assembly forward until bearing is approxi

mately 1/32" from the back of the blade.

Blade guides will align with this adjustment.

Tighten screw.

ADJUSTING LOWER BLADE GUIDES

1.

Loosen the two screws that lock the lower

blade guides and press the two guides evenly

against the sides of the blade but do not

pinch the blade. Release the guides and ro

tate the upper wheel slightly clockwise mov

ing the blade downward. Make sure one

guide is not further away from the biade than

the other. Tighten both screws.

NOTE:

After all adjustments have been made,

turn the upper wheel by hand (clockwise) a few

turns to check blade travel and clearance.

12