Assembly – Craftsman 113.244513 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

assembly

9.

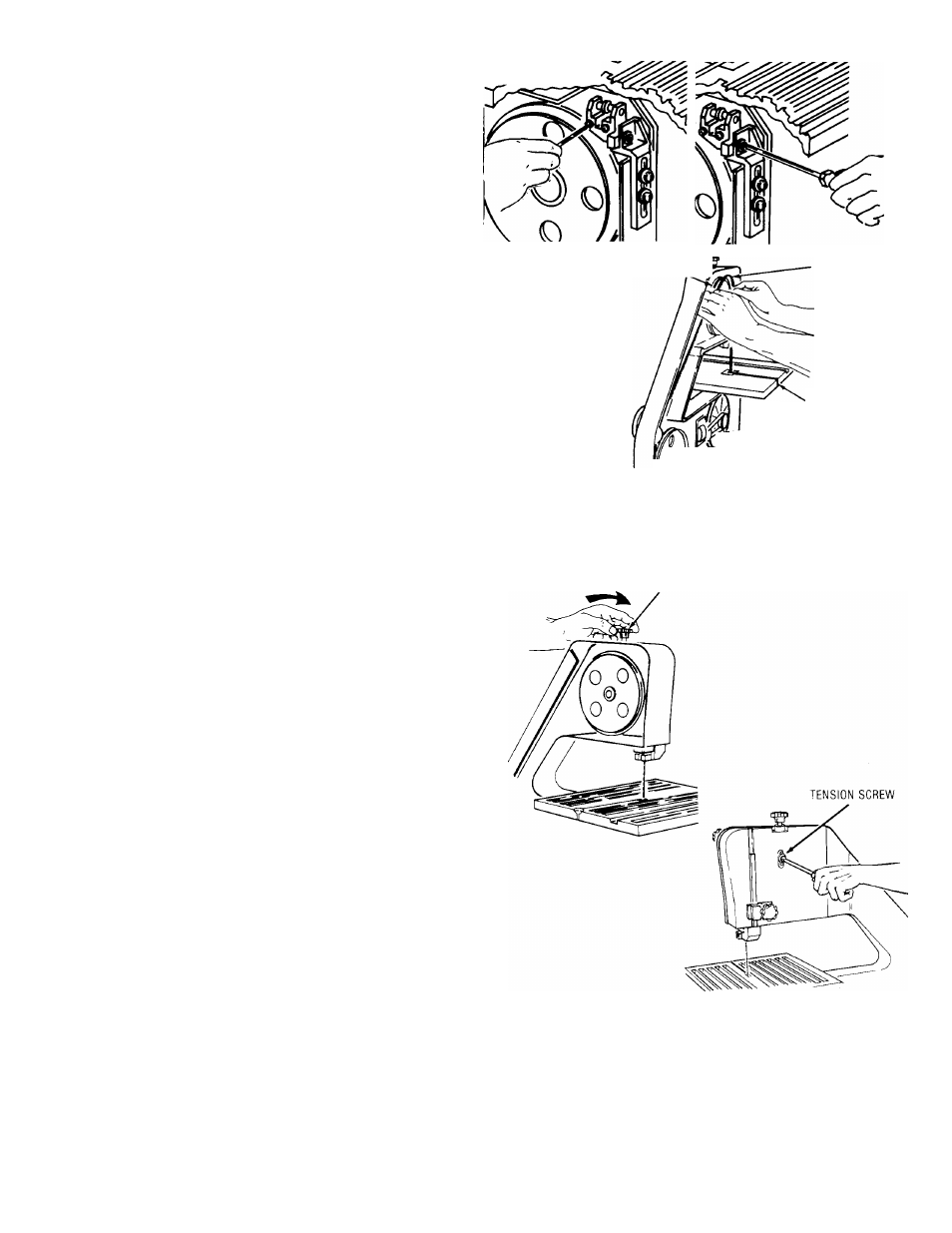

Loosen the two screws that secure the lower

blade guides and separate them about 1/8".

10.

Loosen the screw holding the lower blade

guide support and slide support all the way

toward the rear of the saw, and retighten all

screws.

WARNING:

TO

AVOID

BEING

SCRAPED

SHOULD BLADE SUDDENLY UNCOIL, WEAR

SAFETY GOGGLES AND CAREFULLY UNCOIL

THE BLADE HOLDING IT AT ARMS LENGTH.

11. Place the blade over the wheels with the

teeth pointing downward toward the table as

shown. Make sure the blade is in the center

of the rubber tires.

NOTE:

Your bandsaw can use 1/8 or 1/4 inch wide

blades, 56-7/8 inches long. A 1/4 inch blade is included

with this saw.

TENSION WHEEL

BLADE

SLOT IN TABLE

DRIVE WHEEL

IDLER WHEEL

TENSIONING THE BLADE

The bandsaw is equipped with a self-limiting

tension device. The tension is factory set and

should not need adjustment. The blade must be

installed before tension can be set.

1.

Turn tension adjustment knob until knob

contacts washer and sleeve.

2.

DO NOT turn knob after contact is made and

resistance if felt. This is the proper tension

setting for a 1/4” blade.

3.

To release tension turn knob counterclock

wise until knob is above the washer and

sleeve.

COMPENSATION FOR WEAR

Tension screw is provided to make minimal

adjustments due to wear. The tension screw

creates a drag between the wheel guide and the

frame.

1. Remove the blade before adjusting.

2.

Use a phillips screw driver to adjust the ten

sion screw. Turn clockwise to increase the

drag (tension).

3.

Check tension by lifting up on tension knob. If the

tension knob will not move the tension screw is too

tight. Adjust by turning tension screw coun

terclockwise and recheck.

TENSION

ADJUSTING

KNOB

WARNING: OVER TENSION AND FAILURE TO

PROPERLY SET BLADE GUIDES AND THRUST

BEARING WILL CAUSE PREMATURE BLADE

BREAKAGE.

FOLLOW

ADJUSTING

BLADE

GUIDE ASSEMBLIES COMPLETELY TO HELP

MAINTAIN NORMAL BLADE LIFE.

10