Tire care, To remove wheel, To replace ground drive belt – Craftsman 917.293320 User Manual

Page 16: Ground drive belt adjustment

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TIRE CARE

.

A

c

AUTION;

When mourtting tires, un

less beads are seated, overinflation can

cause an explosion. .

• Maintain 20 pounds of air pressure. If

tire pressures are not equal, tiller will

pull to one side.

• Keep tires free of gasoline or oil which

can damage rubber.

■

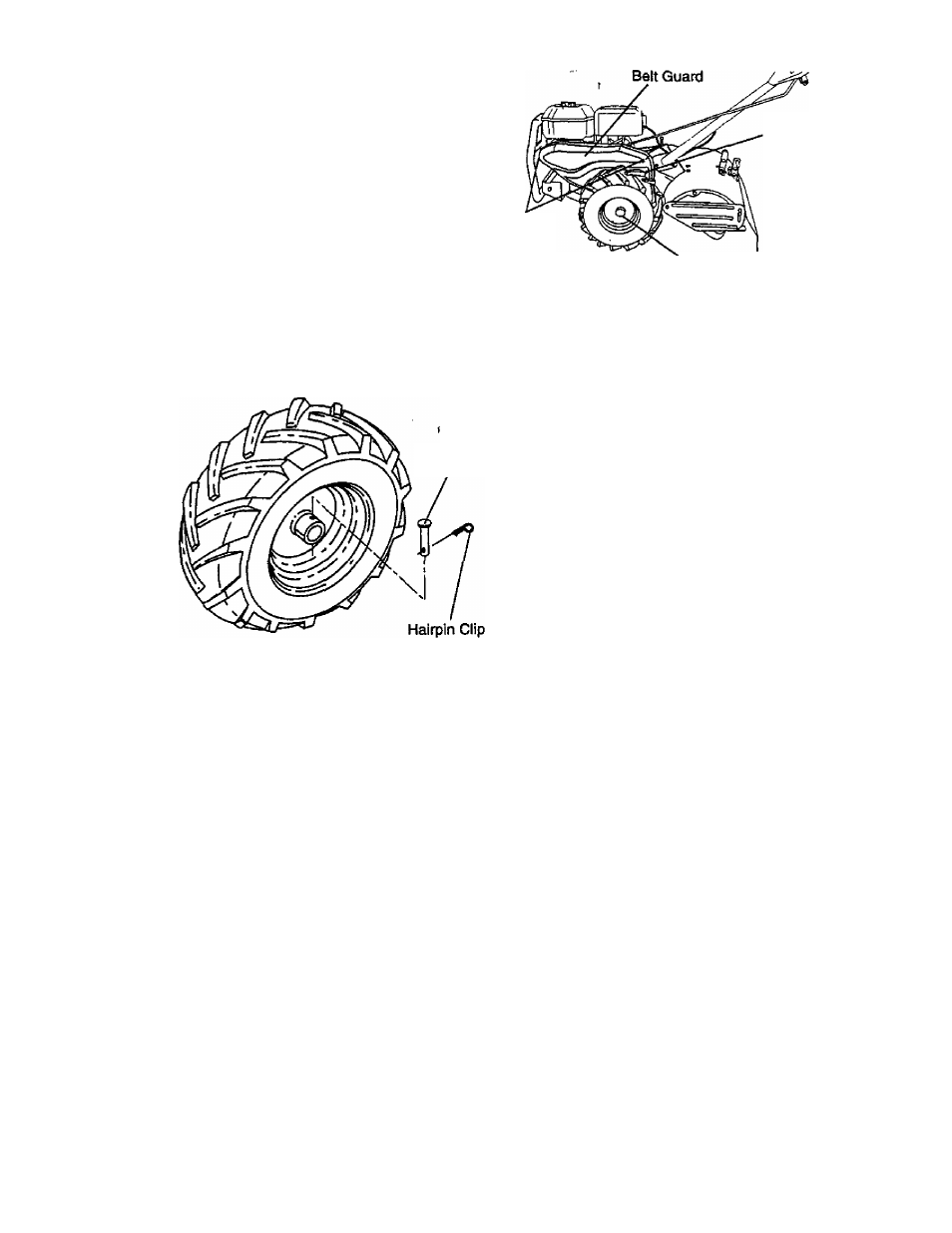

TO REMOVE WHEEL

• Place blocks under transmission to keep

tiller from tipping.

• Remove haiipin clip and clevis pin from

wheel.

• Remove wheel and tire.

• Repair tire and reassemble. ■

Clevis Pin

Screws

TO REMOVE BELT GUARD

NOTE:

For ease of removal, remove hair

pin clip and clevis pin from left wheel. Pull

wheel out from tiller about 1 inch.

• Remcve two {2) screws, one (1) nut and

washer from side of belt guard.

• Pull belt guard out and away from unit.

• Replace belt guard by reversing above

procedure.

Hex Nut

and

Washer

(Located

Behind

Tire)

Hairpin Clip and Clevis Pin

TO REPLACE GROUND DRIVE

BELT

• Remove belt guard as described in TO

REMOVE BELT GUARD”.

• Remove old belt by slipping off engine

pulley first then remove from transmis

sion pulley.

• Place new belt in groove of transmis

sion pulley and into engine pulley. BELT

MUST BE IN GROOVE ON TOP OF

IDLER PULLEY. NOTE POSITION OF

BELT TO GUIDES.

• Check belt adjustment as described

below.

• Replace belt guard.

• Reposition wheel and replace clevis pin

and hairpin clip.

GROUND DRIVE BELT ADJUST

MENT

For proper belt tension, the extension

spring should have about 5/8 inch stretch

when drive control bar is in “ENGAGED”

position. This tension can be attained as

follows;

• Loosen cable clip screw securing the

drive control cable.

• Slide cable fon/vard for less tension and

rearward for more tension until about 5/8

inch stretch is obtained while the drive

control bar Is engaged.

• Tighten cable clip screw securely.

16