Static pressure requirement chart – Craftsman 152.213361 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

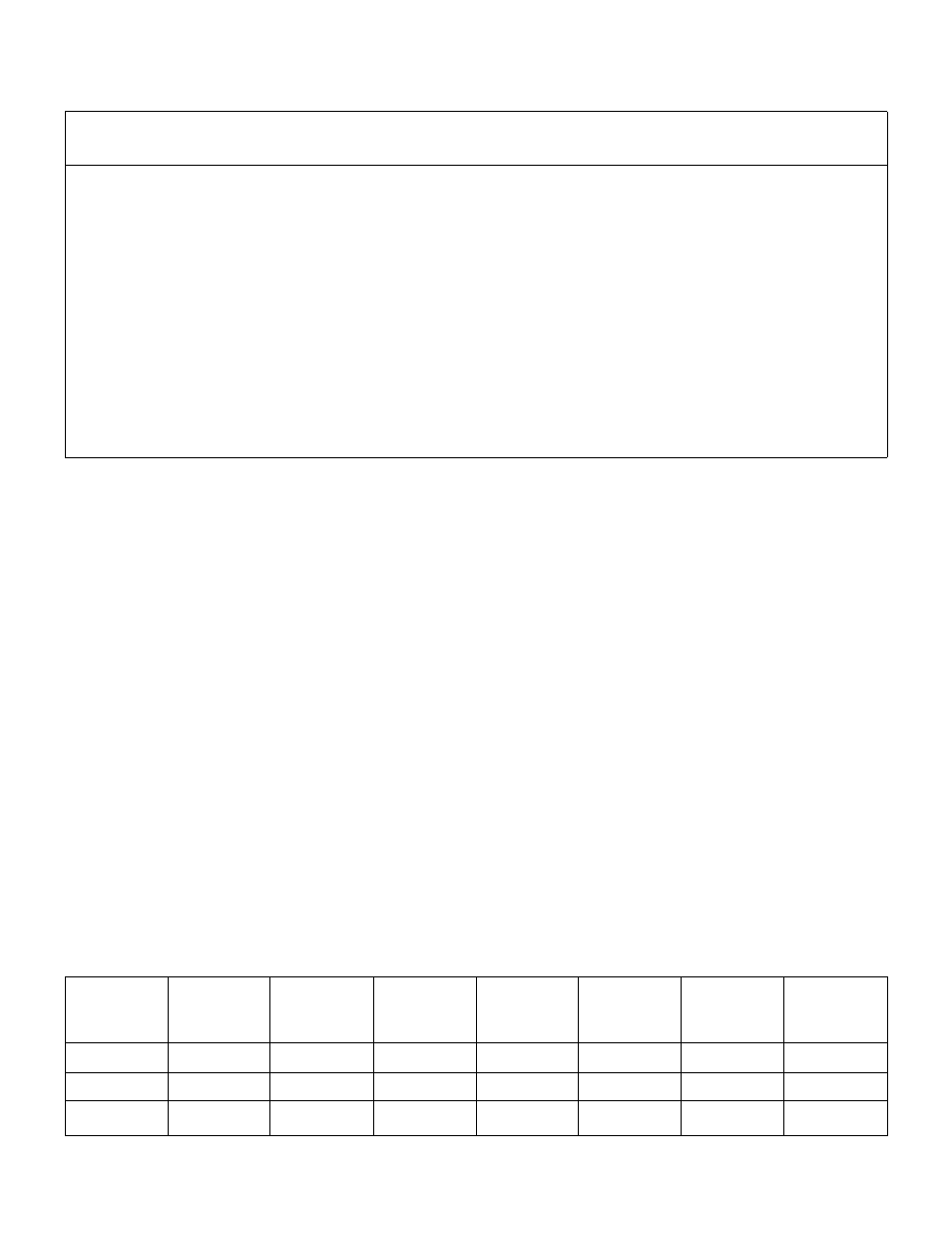

C.F.M. REQUIREMENTS FOR TOOLS

Machine

Minimum C.F.M. Required

Minimum Duct Diameter

Band Saw (12 to 16-inch)

350 C.F.M.

4-inch

Belt/Disc Sander

450 C.F.M.

5-inch

Drill Press

350-400 C.F.M.

4-inch

Drum Sander (12 to 24-inch)

550-700 C.F.M.

5-inch

Floor Sweep

350-400 C.F.M.

4 to 5-inch

Jointer (up to 8-inch)

350-400 C.F.M.

4 to 5-inch

Jointer (over 8-inch)

450-550 C.F.M.

5-inch

Radial Arm Saw

450-600 C.F.M.

5-inch

Miter Saw

450-600 C.F.M.

5-inch

Router Table

200 C.F.M.

3-inch

Scroll Saw

200 C.F.M.

3-inch

Spindle Sander

400 C.F.M.

4-inch

Table Saw (10-inch)

350 C.F.M.

4-inch

Thickness Planer (10 to 15-inch)

400 C.F.M.

4-inch

Thickness Planer (16 to 20-inch)

600-800 C.F.M.

5 to 6-inch

STATIC PRESSURE REQUIREMENTS FOR A DUST COLLECTION SYSTEM

Using STEPS 1 thru 4 and the “Static Pressure Requirement Chart” you can determine the static pressure required

for your Dust Collector.

Step #1: Multiply the number of feet of Hose/Pipe times the appropriate inches rating.

Example: AQ feet of 4-inch diameter ribbed tubing x .11 =4.4 Total

Step #2: Multiply the fittings times the ratings and add them together.

Example:Jvio 90-degree Elbows (using 4-inch diameter Hose) = .84 PLUS two 90-degree T-fittings = .98

Total = 1.82

Step #3: Add 2.5 for the Machine Hook-up and “Dirty Bag" factors (1.5 for Hook-ups + 1.0 for Dirty Bag).

Step #4: Total the above three calculations. This total should not exceed the maximum static

pressure for your Dust Collector.

Example: AA (Total Step #1) x 1.82 (Total Step #2) + 2.5 (Total Step #3) = 8.72

For this example a Dust Collector with a Static Pressure rating of over 8.72 or higher is required.

See Product Specifications on page 2 for your dust collector maximum static pressure.

NOTE: To determine if you have met the Static Pressure Requirement when using a Dust Collection System, identify

the branch of the system with the highest static pressure requirement first. If you run your Dust Collection System with

more than one blast gate open, add the static pressure from all branches that are open to determine the total static

pressure requirements.

Static Pressure Requirement Chart

Size of Hose

Hose/Pipe

Rigid Pipe

(per foot)

Ribbed Tubing

(per foot)

90-degree

Elbow

90-degree

Elbow

45-degree

T-fitting

Machine

Hook-Up

“Dirty Bag”

Adjustment

3

.10

.15

.50

.60

.25

1.50

1.0

4

.07

.11

.42

.49

.21

1.50

1.0

5

.055

.08

.49

.55

.25

1.50

1.0

15