A warning, Fig.r, Fig.s – Craftsman 137.218250 User Manual

Page 14: Blade tilt pointer, Blade parallel to miter gauge groove (fig.t,u), Initial adjustment (fig.t), 45° stop

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A WARNING

To avoid injury from an accidental start, make sure the

switch is in the OFF position and the plug is not

connected to the power source outlet.

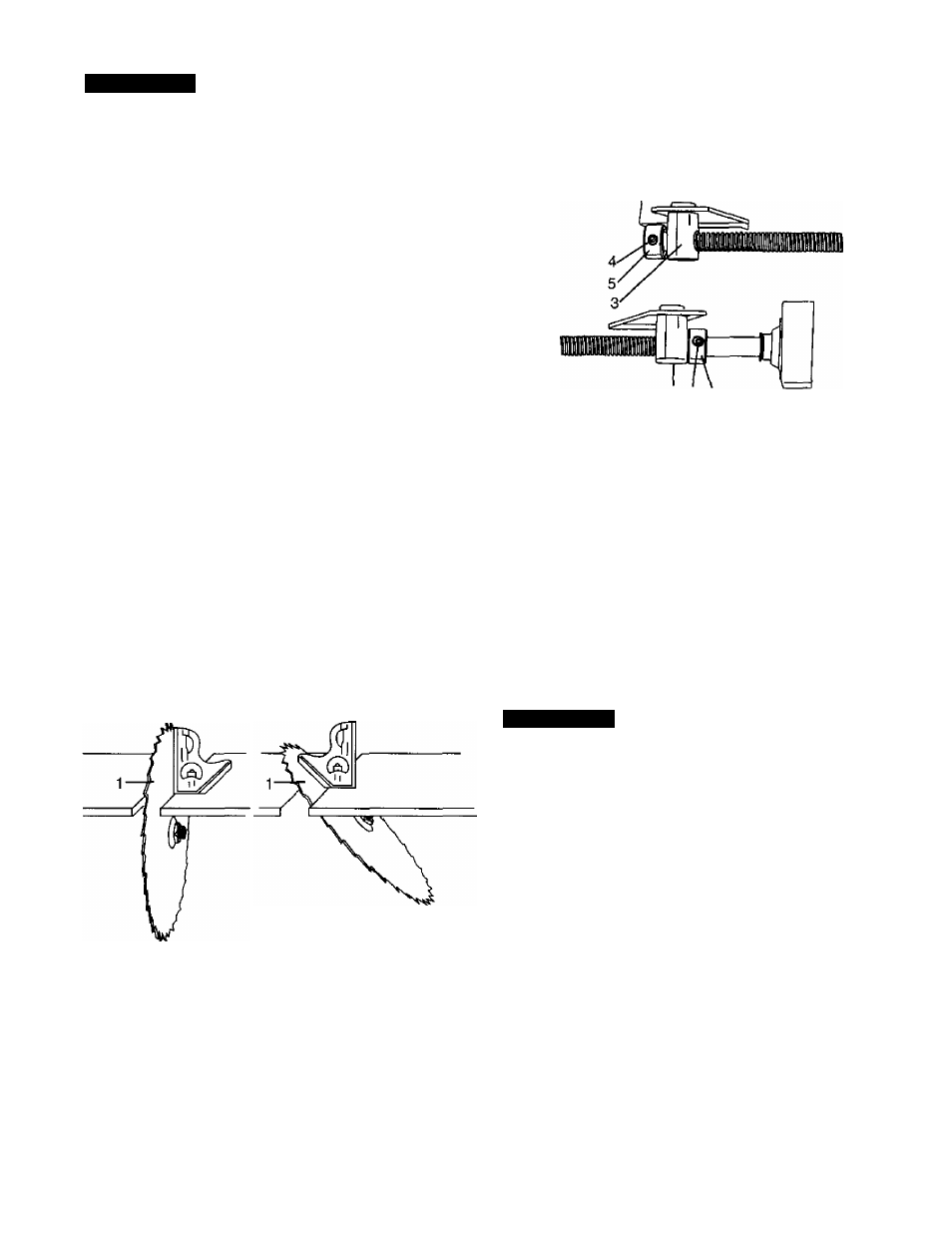

ADJUSTING THE 90° AND 45° POSITIVE STOPS

(FIG. R, S)

Your saw has positive stops that will quickly position the

saw blade at 90° or 45° to the table. These stops were

set at the factory. Make adjustments only if necessary.

90

1

.

2

.

3.

4.

6

.

7.

° Stop

Disconnect the saw from the power source.

Turn the blade elevation handwheel and raise the

blade to the maximum elevation.

Loosen the blade bevel lock knob and move the

blade to the maximum vertical position. Tighten the

lock knob.

Place a combination square on the table and

against the blade (T) to determine if the blade

is 90° to the table. (FIG. R)

If the blade is not 90° to the table, loosen the two

set screws (4), located in the bottom of the table saw,

(FIG. S) with the 3mm hex key, and back off the

collar (5).

Loosen the bevel lock knob. Turn the blade tilting

handwheel to move the blade until it is 90° to the

table.

Adjust the collar (5) so it contacts the bracket (3)

when the blade is 90° to the table. Tighten the

two set screws (4),

Fig.R

90'

45'

4.

Loosen the bevel lock knob; turn the tilting

handwheel to move the blade until it is 45° to the

table,

5. Adjust the collar (5) so it contacts the bracket (3)

when the blade is 45°, Tighten set screws (4).

Fig.S

3 4 5

BLADE TILT POINTER

1. When the blade is positioned at 90°, adjust the

blade tilt pointer to read 0° on the scale.

2.

Loosen the holding screw, position the pointer over

0° and tighten the screw.

NOTE:

Make a trial cut on scrap wood prior to making

critical cuts. Measure for exactness.

BLADE PARALLEL TO MITER GAUGE

GROOVE (FIG.T,U)

This adjustment was made at the factory, but it should

be rechecked and adjusted if necessary.

A WARNING

To prevent personal injury:

•

Always disconnect plug from the power source when

making any adjustments.

•

This adjustment must be correct or kickback could

result and accurate cuts cannot be made.

Initial adjustment (FIG.T)

45° Stop

1. With the blade in the upright 90° position, loosen the

bevel lock knob. Turn the blade tilting handwheel and

move the blade to the 45° position as far as it will go.

2. Place the combination square on the table as shown

in

(FIG. R)

to check if the blade is 45° to the table.

3. If the blade is not 45° to the table, loosen the two set

screws (4) located under the table saw (FIG. S) with

a 3 mm hex key, and back off the collar (5).

1

.

2

.

3.

4.

5.

6

.

7.

Remove the yellow switch key and unplug

the saw.

Move the blade guard out of the way.

Raise the blade to the highest position and set at

the 0° angle {90° straight up).

Select and mark, with a felt tip marker, a blade

tooth having a “right set”.

Place the combination square base (1) into the

right side miter gauge groove (2). (FIG.T)

Adjust the rule so it touches the front marked tooth

and lock the ruler so it holds its position in the

square assembly.

Rotate the blade bringing the marked tooth to the

rear and about 1/2 inch above the table.

14