A warning – Craftsman 137.224320 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

To avoid twisting the blade, do not turn sharp corners, saw

around corners.

A band saw Is basically a "curve-cutting" saw. It is not

capable of doing intricate inside cutting as can be done with

a scroll saw.

It is also used for straight line operations such as

crosscutting, ripping, mitering, beveling, compound cutting,

and resawing.

A WARNING

To avoid blade breakage, fire or other damage or injury,

NEVER use this band saw to cut ferrous metals.

CUTTING CURVES

When cutting curves, carefully turn the workpiece so the

blade follows without twisting. If the curve is so sharp that

you repeatedly back up and cut new kerf, use a narrower

blade, or a blade with more set {teeth further apart). When a

blade has more set, the workpiece turns easier but the cut is

rougher.

When changing a cut, do not withdraw the workpiece from

the blade, The blade may get drawn off the wheels. To

change a cut, turn the workpiece and saw out through the

scrap material area.

When cutting long curves, make relief cuts as you go along.

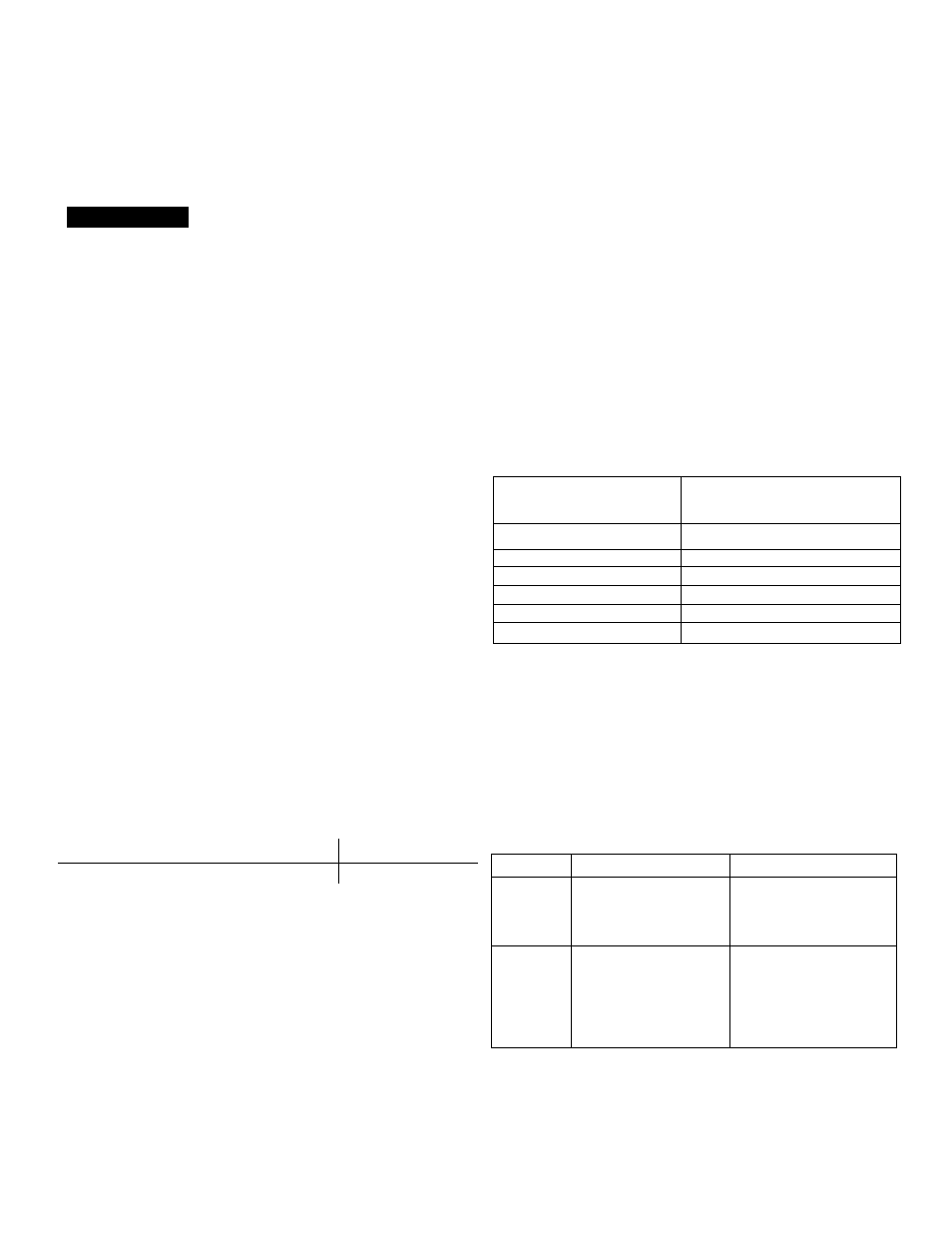

CIRCLE CUTTING (FIG.V)

1. Adjust the guide assembly to 1/8" above the workpiece.

2. Use both hands while feeding the work into the blade.

Hold the workpiece firmly against the table. Use gentle

pressure. Do not force the work, ALLOW the blade to cut

3. The smallest diameter circle that can be cut is

determined by the width of the blade. For example,

a 1/4" wide blade will cut a minimum diameter of

approximately 1-1/2".

FIG.V

BLADE SELECTION (FIG. W)

CAUTION:

Blade teeth are sharp. Use care when handling a

saw blade.

For longest wear and best cutting results, use the correct

blade thickness, width, and temper for the type of material

you will cut.

When sawing small curves and delicate work, use narrow

blades. Otherwise, use the widest blade possible,

For cutting wood and similar materials with this bandsaw,

purchase blades in widths up to 1/2", and a length of 80".

Do not cut ferrous metals with this band saw.

Common causes of blade breakage:

® Poor guide alignment and adjustment,

® Forcing or twisting a wide blade around a short radius.

® Feeding too fast.

»

Dull teeth or not enough set.

® Too much blade tension,

® Setting top guide assembly too high above the workpiece.

“ Lumpy or improperly finished braze or weld on the blade.

« Continuous running of blade when not cutting.

FIG. W

Operation

Recommended Blade Width

(Inches)

Cross Cutting

1/4, 3/8, 1/2

Mitering

1/4, 3/8, 1/2

Beveling

1/4, 3/8, 1/2

Compound Cutting

1/4, 3/8, 1/2

Circle Cutting

See Fig. V

Curve Cutting

1/8, 1/4

BLADE SPEED SELECTION {FIG. X)

This band saw has two speed settings;

1,2600 F.P.M. for normal operation,

2,1410 F.P.M. for operation requiring more control.

RECOMMENDED SPEEDS

f \

1/2"

d

\

ro

I 2"D

2-1/2" D

Minimum

Circle Diameter

k / /

3ÌS'

i 1/4"

I 3B "

1/2'

Blade Width

FIG. X

SPEED

APPLICATION

BLADETYPE

2600 FP.M,

1. Basic wood cutting

2. Resawing

I.Skip tooth type

2. Hook tooth type

3. Regular tooth blades

1410 F.P.M.

1. Intricate wood cutting

2. Veneers, tiles,

plastics

3. Nonferrous metals;

brass, copper,

aluminum

15 teeth per inch blades

■fl 7 :