A warning, Operation basic saw operations – Craftsman 137.224320 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

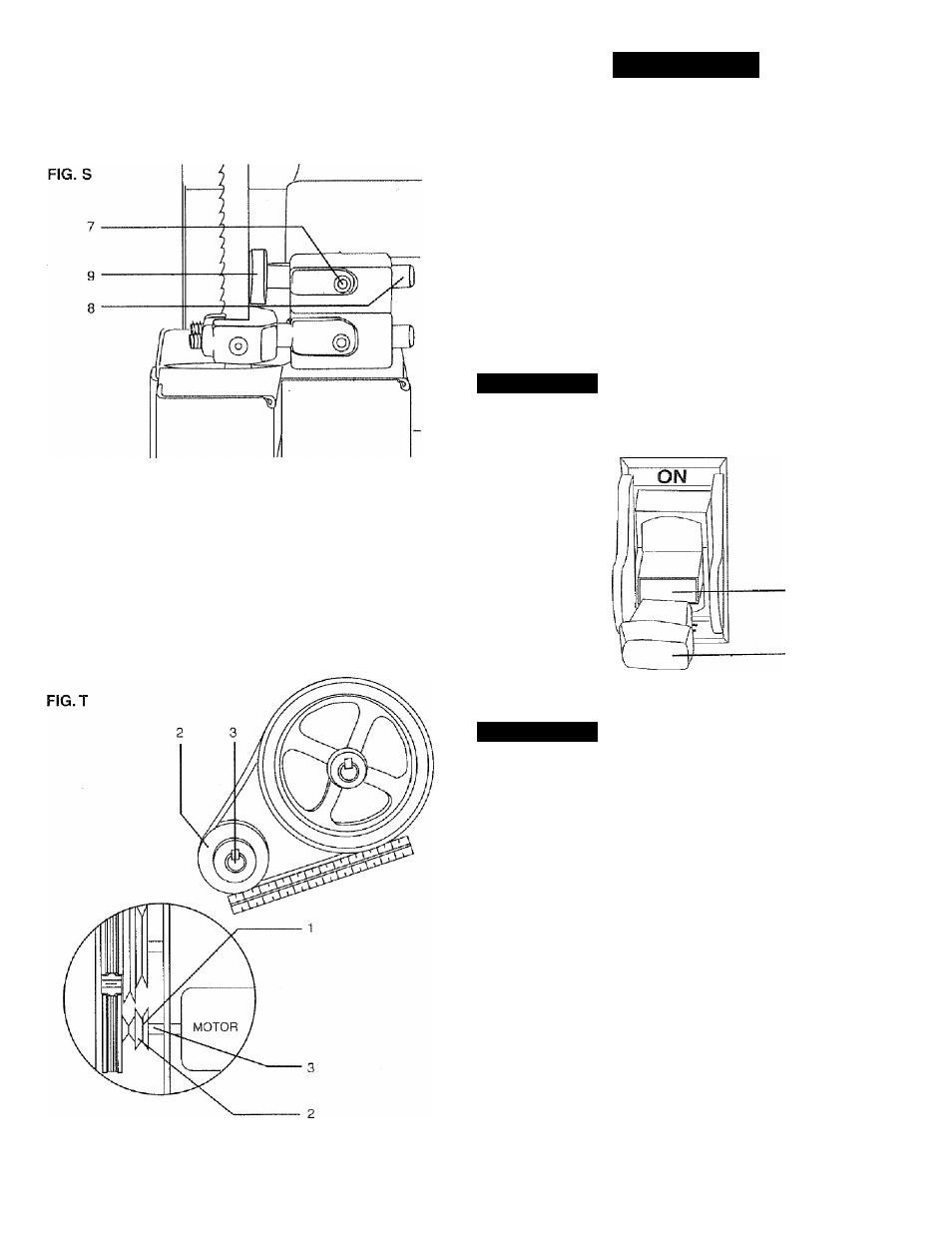

Support bearing (FIG. S)

6. Loosen the bearing hex socket screw (7) with the hex

wrench.

7. Move the blade support bearing shaft (8) in or out until

the support bearing (9) is 1/64" behind the saw blade.

8. Tighten the bearing hex socket screw.

Pulley alignment (FIG.T)

The pulley alignment is adjusted properly at the factory and

should not need readjustment.

If adjustment is needed, or the belt needs replacing:

1. Place a.straight edge in the front groove of both pulleys,

behind the blade wheel.

2. Turn the hex socket screw (1) in the side of the motor

pulley (2) to loosen the pulley on the shaft.

3. Adjust the motor pulley in or out on the motor shaft (3)

to align the edges of the two pulieys.

4. When aligned, tighten the hex socket screw on the side

of the motor pulley.

OPERATION

BASIC SAW OPERATIONS

ON / OFF SWITCH (FIG. U)

The keyed switch is intended to prevent unauthorized

use of the band saw.

1. To turn the band saw ON insert the yellow key (1) into

the key slot (2) in the center of the switch.

2. Push the key firmly into the slot, then push switch

to the ON position to start the band saw.

3. To turn the band saw OFF push the switch to the

down position.

4. Remove the yellow switch key, when the saw has come

to a complete stop, by gently pulling it outward.

A WARNING

Remove the switch key whenever the saw is not in use.

Place it in a safe piace and out of reach of children.

FIG. U

GENERAL CUTTING

A WARNING

For your safety, read and understand all GENERAL and

SPECIFIC SAFETY INSTRUCTIONS on pages 3 - 5 before

using the band saw.

Operating band saws involves a certain amount of hazard.

Before attempting regular work, use scrap lumber to check

the settings, and to get the feel of operating the band saw.

Read instructions and plan your work before cutting a

workpiece,

Do not turn the power ON until after you have made all

adjustments, checked that the guard is in place, and turned

the wheel by hand to make sure all parts work properly.

Always keep the guide assembly close to your work, 1/8"

above the workpiece.

Do not force the workpiece, against the blade. Light contact

permits easier cutting and prevents unwanted friction and

heating of the blade.

Sharp saw blades need little pressure for cutting. Steadily

move the workpiece against the blade without forcing it.

1 6 i