Orbital motion, Maintenance, General maintenance – Craftsman 315.279840 User Manual

Page 12: Lubrication, Operation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

Do not force. The weight of the unit supplies adequate

pressure. Let the sandpaper and sander do the work. Ap

plying additional pressure sfows the motor, rapidly wears

sandpaper and greatly reduces sander speed. Excessive

pressure will overload the motor causing possible damage

from motor overheating and can result in inferior work.

Any finish or resin on wood may soften from the frictional

heat. Do not allow sanding on one spot too long, as the

Sander's rapid action may remove too much material,

making the surface uneven.

The front edge of the sander allows flush sanding in

corners. Always remove sander from workpiece before

turning the sander.

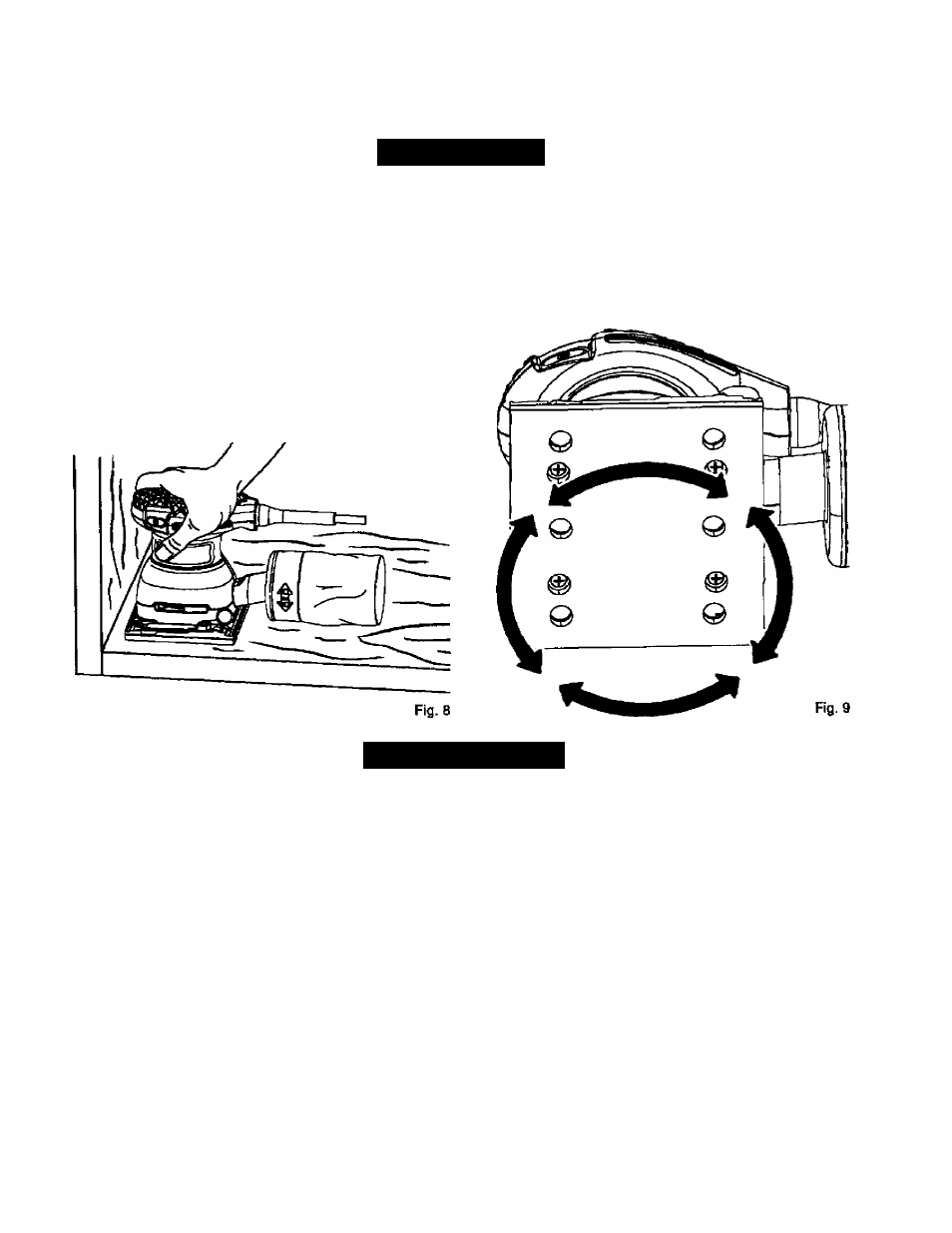

ORBITAL MOTION

See Figure 9.

Orbital motion is ideal for fast cutting action when remov

ing old finishes, smoothing rough wood, cutting stock

down to required dimensions, or for finishing surfaces to

be painted. The sandpaper moves in tiny circles at a very

high speed, allowing the sander to move easily.

MAINTENANCE

▲

WARNING:

When servicing, use only identicat

Craftsman replacement parts. Use of any other parts

may create a hazard or cause product damage.

WARNING:

Aturays wear safety gaggles or safety

' glasses with side shields during power tool operation

or when blowing dust, if operation is dusty, also wear

a dust mask.

GENERAL MAINTENANCE

Avoid using sofvenCs when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, oil, grease, etc.

A

WARNING:

Do

not at any time let brake fluids,

gasoiine, petroleum-based products, penetrating

oils, etc., come in contact with plastic parts. Chemi

cals can damage, weaken or destroy plastic which

may result In serious personal injury.

Electric tools used on fiberglass material, wallboard,

spackllng compounds, or plaster are subject to accel

erated wear and possible premature failure because the

fiberglass chips and grindings are highly abrasive to bear

ings, brushes, commutators, etc. Consequently, we do not

recommended usii^ this tool for extended work on these

types of materials. However, if you do work with any of

these materials, it is extremely important to clean the tool

using compressed air.

LUBRICATION

All of the bearings in this tool are lubricated with a suffi

cient amount of high grade lubricant for the life of the unit

under normal operating conditions. Therefore, no further

lubrication is required.

Only the parts shown on the parts list are intended to be

repaired or replaced by the customer. All other parts

should be replaced at a Sears Service Center.

12