Carrier 50ZHA024-060 User Manual

Page 9

LOW CHARGE COOLING

024-042 units:

1. Measure suction line pressure by attaching a gauge to the

service port.

2. Measure the suction line temperature by attaching a tempera-

ture sensing device to it.

3. Insulate the temperature sensing device so that the outdoor

ambient doesn’t affect the reading.

4. Locate the measured suction line pressure in the top row of

Table 8 and the measured outdoor ambient temperature in the

left column of the table. Based on the two values, determine

the required suction line temperature.

5. If the measured suction line temperature is greater than the

tabulated temperature, add charge in the system.

048 and 060 units:

1. Measure discharge line pressure by attaching a gauge to the

service port.

2. Measure the liquid line temperature by attaching a temperature

sensing device to it.

3. Insulate the temperature sensing device so that the outdoor

ambient doesn’t affect the reading.

4. Refer to the required subcooling in Tables 4 and 5 to find the

required subcooling based on the model size and the outdoor

ambient temperature.

5. Interpolate if the outdoor temperature lies in between the table

values. Extrapolate if the temperature lies beyond the table

range.

6. Find the pressure value corresponding to the measured pres-

sure on the compressor discharge line.

7. Read across from the pressure reading to obtain the Liquid line

temperature for a required subcooling.

8. Add charge if the measured temperature is higher than the

liquid line temperature value in the table.

9. Add charge using the service connection on the suction line of

the compressor.

HEATING MODE CHARGE

Do not attempt to adjust charge by cooling methods while in heat

pump heating mode. Recover refrigerant and weigh in according to

unit data plate refrigerant data.

Step 4—Indoor Airflow and Airflow Adjustments

NOTE: For cooling operation, the recommended airflow is 350 to

450 cfm per each 12,000 Btuh of rated cooling capacity.

Table 7 shows dry coil air delivery for horizontal discharge units.

Tables 9-11 show pressure drops.

NOTE: Be sure that all supply- and return-air grilles are open,

free from obstructions, and adjusted properly.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect electrical power to the unit and install lockout tag

before changing blower speed.

Airflow can be changed by changing the 24 volts lead connections

of the blower motor.

Unit 50ZHA blower motors are factory wired for rated airflow

operation.

FOR 208/230-V BLOWER MOTORS

The motor lead speed connections are as follows:

SIZE

RATED AIRFLOW

HIGH AIRFLOW

024

Tap 1

Tap 3

030

Tap 2

Tap 4

036

Tap 1

Tap 3

042

Tap 2

Tap 4

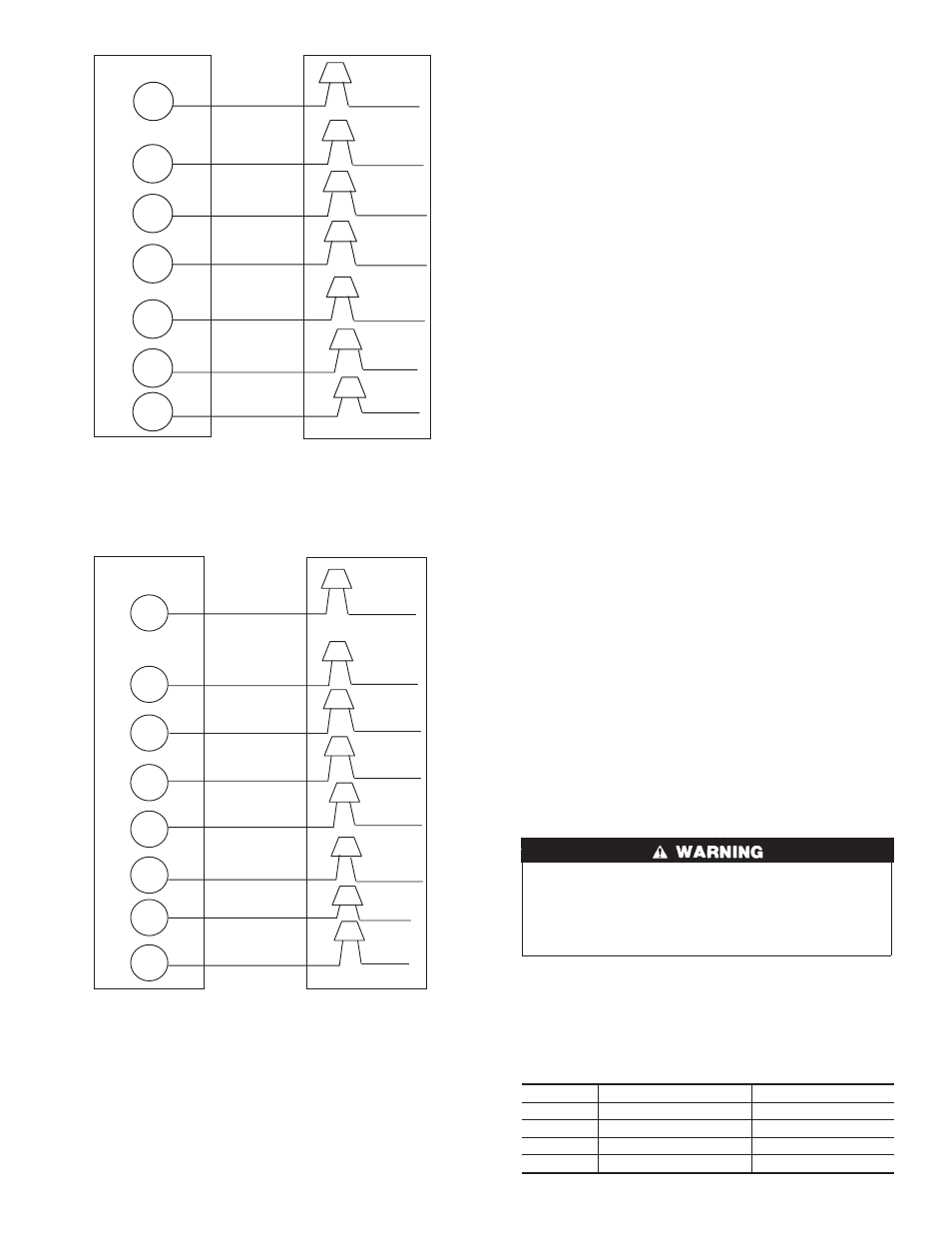

Thermostat

Unit Control

G

Y

W2

W3

R

RED

GREEN

YELLOW

O

ORANGE

C

BROWN

WHITE

VIOLET

and subbase

Power

A05207

Fig. 10A—Control Connections (Sizes 024-042)

Thermostat

Unit Control

G

Y

Y1

O

R

RED

GREEN

YELLOW

W2

PINK

W3

ORANGE

WHITE

VIOLET

C

BROWN

Power

and subbase

A05208

Fig.10B—Control Connections (Sizes 048-060)

9