Taylor-Wharton EF-1500 User Manual

Page 8

BT-481 REV. B

8

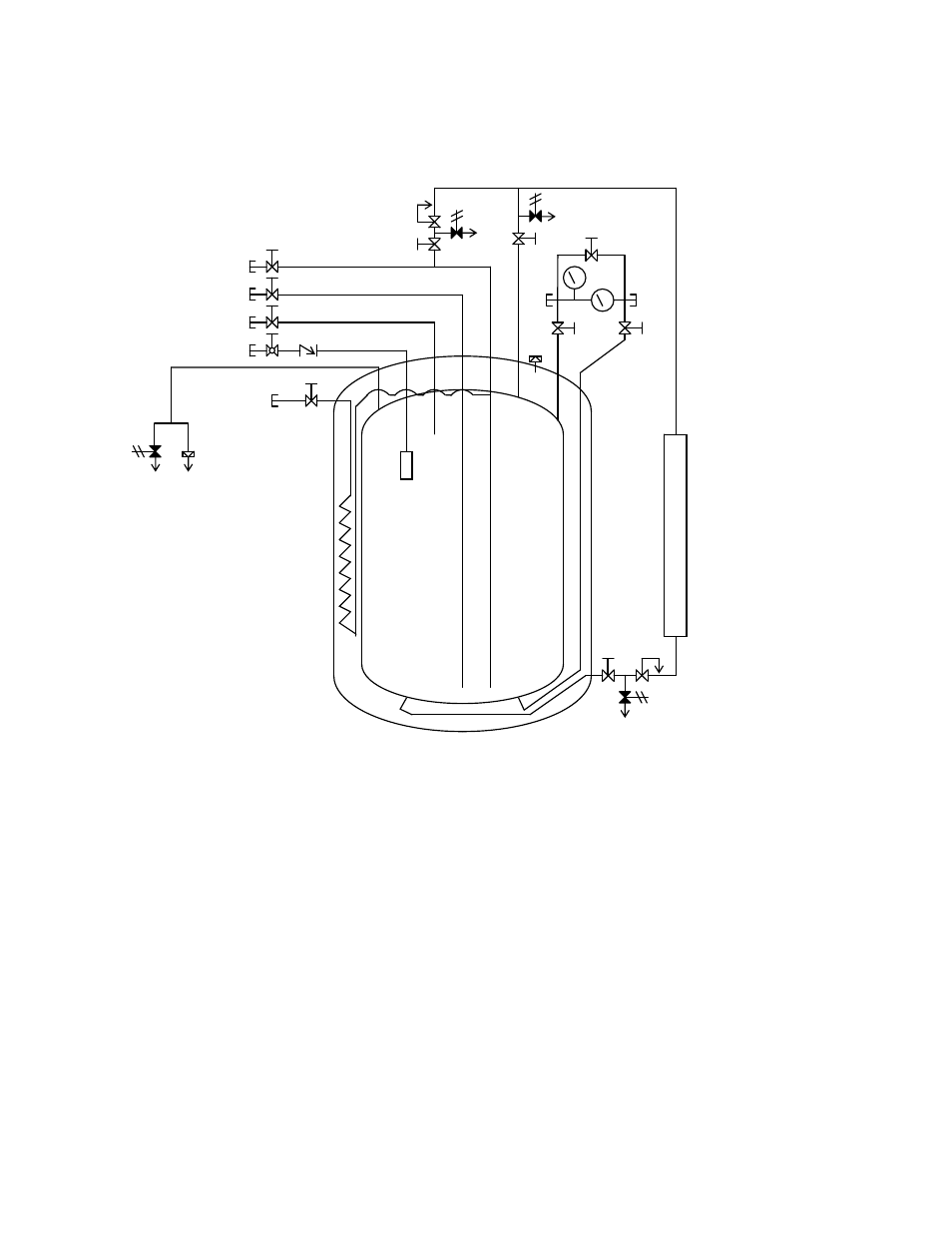

PIPING CIRCUITS

The following paragraphs describe the operation of the piping circuits of the system. The descriptions refer to the main

components of each circuit and are grouped by function. Reference the piping schematic below and in the general

arrangement drawing for the component designations. These component and circuit descriptions should be understood

before attempting operation.

Legend

CN-1

Connection, Pump / Top Fill

V-10

Valve, Liquid Phase Isolation

CN-2

Connection, Full Trycock & Vent

V-11

Valve, Gas Use

CN-3

Connection, Liquid Fill / Withdrawal

CV-1

Check Valve, Pump / Top Fill

CN-4

Connection, Vaporizer Inlet (External)

LI-1

Liquid Level Gauge

CN-5

Instrument Connection, Liquid Phase

PI-1

Pressure Gauge

CN-6

Instrument Connection, Vapor Phase

PBC-1

Pressure Building Coil

CN-7

Connection, Vaporizer Outlet (Internal)

PCV-1

Pressure Building Regulator

V-1

Valve, Pump / Top Fill

PCV-2

Economizer Regulator

V-2

Valve, Full Trycock / Vent

SV-1**

Safety Valve

V-3

Valve, Liquid Fill / Withdrawal

SV-2

Relief Valve

V-4

Valve, Vaporizer Inlet

SV-3

Relief Valve

V-5

Valve, Economizer Isolation

SV-4

Relief Valve

V-6

Valve, Pressure Building Outlet

R-1**

Inner Container Safety Disc

V-7

Valve, Pressure Building Inlet

R-2

Outer Casing Safety Disc

V-8

Valve, Vapor Phase Isolation

FSV-1*

Fill Stop Valve

V-9 Valve,

Equalization

*

Functions with delivery vehicle equipped with automatic filling system, i.e. Taylor-Wharton Express Cryogenic Delivery System.

**

Option for Dual Safeties/Rupture Disc with Diverter Valve.

Figure 1: System Piping Schematic

CN-2

CN-3

CN-4

CN-1

PCV-1

SV-1 R-1

LI-1

V-1

V-2

V-3

V-4

CV-1

FSV-1*

PCV-2

SV-4

V-5

PI-1

V-8 V-10

V-6

V-9

V-7

SV-3

SV-2

CN-6

CN-5

R-2

PBC-1

V-11

CN-7