Taylor-Wharton EF-1500 User Manual

Page 24

BT-481 REV. B

24

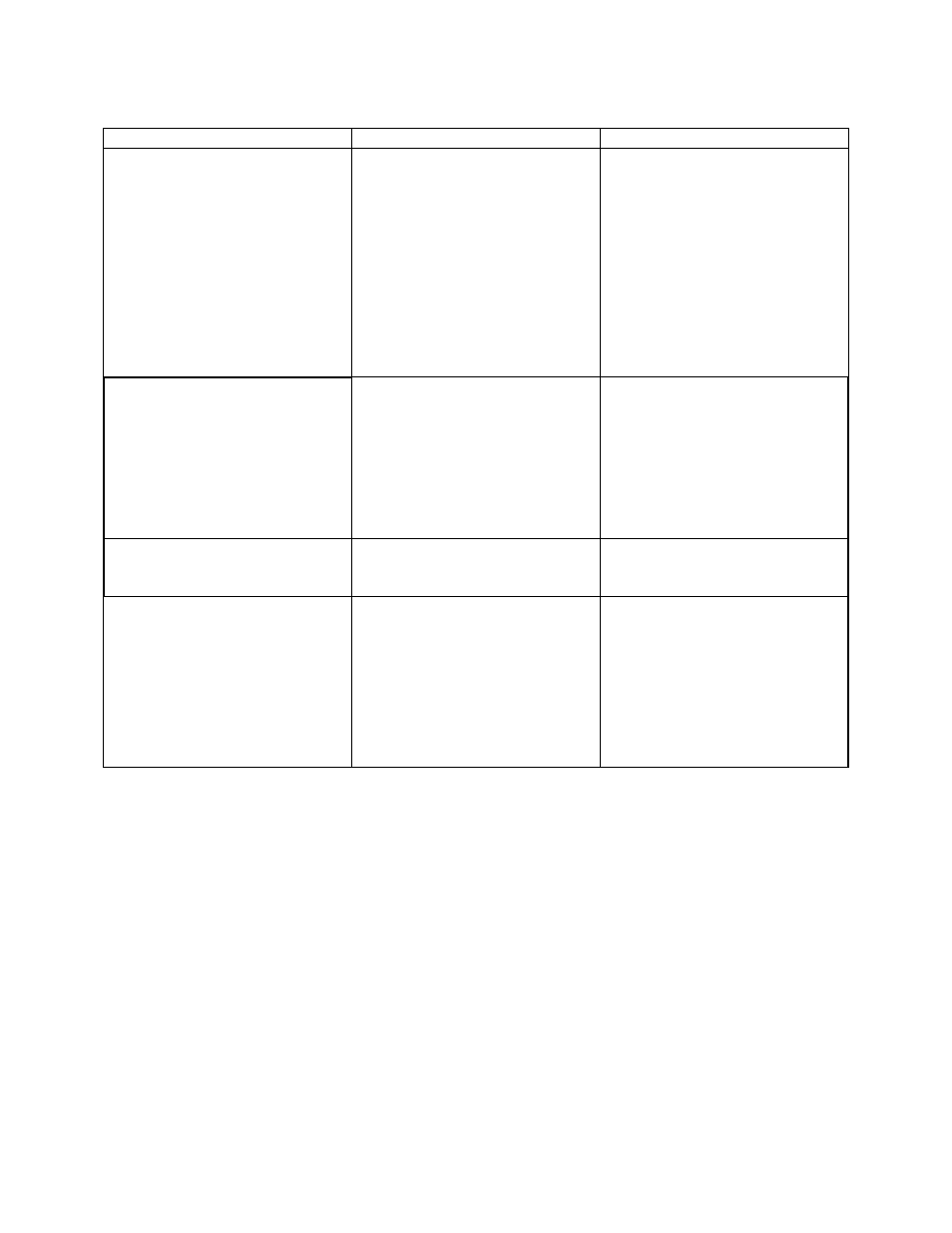

Trouble-Remedy Guide

Trouble Possible

Cause

Remedy

a. Safety valve leaking or frozen

open.

a. Thaw out valve or replace if

necessary.

b. Safety disc ruptured.

b. Replace disc.

c. Piping leaks to atmosphere.

c. Leak test and repair piping.

d. Pressure building / economizer

regulator malfunction.

d. Adjust regulators. Replace if

necessary.

e. Excessive product withdrawal.

e. Check for leaks downstream.

Reduce product use.

f.

Pressure building valve closed.

f. Open pressure building valve.

g. Malfunctioning pressure gauge.

g. Replace pressure gauge.

1. Low operating pressure.

h. Excessive frost on pressure

building coils.

h. Thaw pressure building coils.

a. Extensive shutdown time.

a. No remedy.

b. Low withdrawal rate.

b. No remedy.

c. Malfunction of pressure

building circuit.

c. Adjust pressure building

regulators. Replace if necessary.

d. Malfunction of pressure gauge.

d. Replace gauge.

2. Excessive system pressure.

e. Bad vessel vacuum.

e. Perform NER test. Have vessel

repaired and re-evacuated if

necessary.

a.

Dirt or ice in valve.

a. Thaw out valve. Replace if

necessary.

3. Leaking relief valve.

b.

Damaged valve seat.

b. Replace valve.

a.

Excessive vessel pressure.

a. Refer to Step 2, this section.

Replace rupture disc.

b.

Defective rupture disc.

b. Replace rupture disc.

c.

Atmosphere corrosion and/or

disc fatigue.

c. Replace rupture disc.

d.

Interior disc corrosion.

d. Blow out safety device line.

Replace rupture disc.

4. Ruptured pressure vessel rupture

disc.

e. Relief device failed.

e. Replace relief device and rupture

disc.