Taylor-Wharton EF-1500 User Manual

Page 20

BT-481 REV. B

20

Withdrawing Product

Internal Vaporizer

To withdraw gas from the Express Fill 1,500, connect a suitable line regulator to the gas withdrawal connection (CN-7).

Connect the outlet of the regulator to the application. Follow these steps:

1.

Open the pressure building valve (V-6). Monitor the pressure gauge (PI-1). When the pressure exceeds

the desired delivery pressure, continue.

2.

Open the gas withdrawal valve (V-11).

3.

Adjust the line regulator to desired delivery pressure.

External Vaporizer

To withdraw product from the Express Fill 1,500, connect a suitable vaporizer to the vaporizer inlet connection (CN-4).

Equip the vaporizer with a relief valve sized in accordance with the vaporizer manufacturer’s recommendations. Install a

line regulator downstream of the vaporizer. Connect the outlet of the regulator to the application. Follow these steps:

1.

Open the pressure building valve (V-6). Monitor the pressure gauge (PI-1). When the pressure exceeds

the desired delivery pressure, continue.

2.

Open the vaporizer inlet valve (V-4).

3.

Adjust the line regulator to desired delivery pressure.

Withdrawing Liquid

Attach a transfer hose from the receiver vessel to the Express Fill 1,500 liquid connection (CN-3) and open the adjacent

liquid valve (V-3). The pressure in the container will drive liquid product out through the valve as long as the container

pressure exceeds that of the receiver.

Changing Gas Service

The Express Fill 1,500 may be used for argon, oxygen, or nitrogen service. Follow these steps to properly change gas

service:

1.

Safely empty all liquid from the container.

2.

Open the pressure building inlet and outlet valves (V-6 and V-7) and the vent valve (V-2) to vaporize any

residual liquid that may remain in the bottom of the vessel. It may require an hour or longer to vaporize all

the residual liquid.

3.

To ensure purity, it is recommended that the Express Fill 1,500 be evacuated with a suitable vacuum pump.

The ultimate vacuum reading should be at least 20 inches of mercury.

4.

Replace the fittings for the liquid, top fill, and use connections with the appropriate fittings shown in the

chart below. Use Teflon tape or another suitable thread sealant when threading the fittings into the

connections.

5.

Remove any decals identifying the previous gas service. Attach new gas service identification decals.

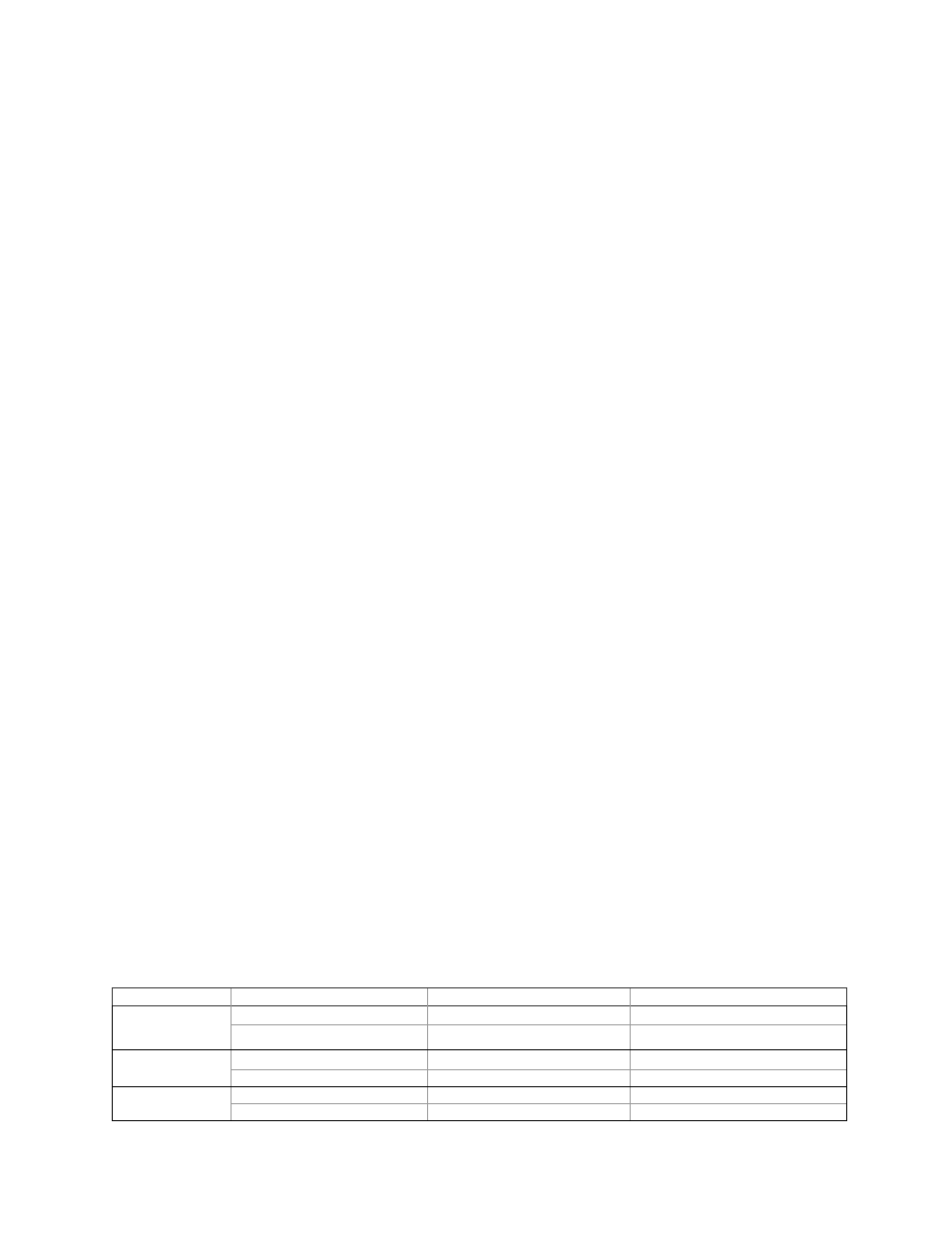

Gas Service

Valve

Description

TW Part Number

Liquid & Top Fill Fitting

CGA 440 x 1/2” NPT

6514-8990 (2 required)

Oxygen

NA

Oxygen Service Decal

GL55-9C52

Liquid & Top Fill Fitting

CGA 295 x 1/2” NPT

7355-4698 (2 required)

Nitrogen

NA

Nitrogen Service Decal

GL55-9C51

Liquid & Top Fill Fitting

CGA 295 x 1/2” NPT

7355-4698 (2 required)

Argon

NA

Argon Service Decal

GL55-9C53