Taylor-Wharton XL-65HP (with dual regulators) User Manual

Page 8

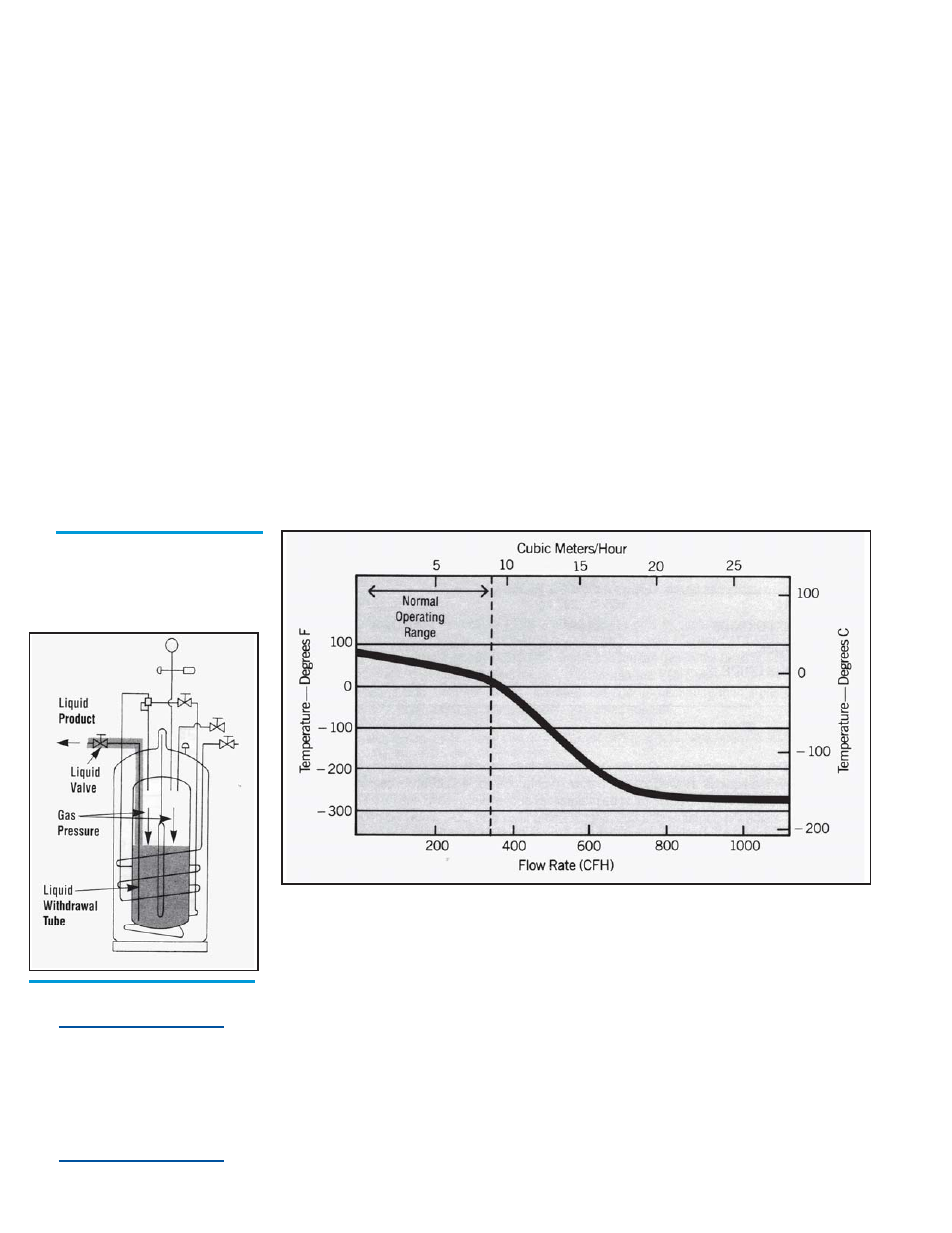

WITHDRAWING GAS FROM THE CONTAINER

To withdraw gas from the XL-65/65HP connect a suitable pressure regulator to the USE

connection, and the output of the regulator to your external equipment. Then open the

USE and the PRESSURE BUILDING valves. When the container pressure reaches 125

psig (8.6 bar/862 kPa) for the XL-65, —or 300 psig (20.7 bar/2069 kPa) for the XL-65HP –

set the pressure regulator for the desired delivery pressure.

Increasing Gas Supply Capacity – Two or more liquid containers may be manifolded

together. Accessory manifolds are available for use in creating a higher capacity gas

supply system. The XL-65/65HP can supply gas flow rates up to 350 cfh @NTP (9.2

cu.m/h @ STP) using only its internal vaporizer. At low rates, the gas supplied will be at

near ambient temperatures. As the flow demand is increased, the gas will become propor-

tionately colder. If greater vaporizing capacity is required, an accessory external vaporizer

is available. When an external vaporizer is used, it must be connected to the USE valve

and the regulator moved to the output of the external vaporizer.

WITHDRAWING LIQUID FROM THE CONTAINER

Attach a transfer hose to the LIQUID connection and open the adjacent LIQUID valve. The

pressure in the container will drive liquid product out through the valve as long as the

container pressure exceeds that of the receiver.

The rate of liquid withdrawal from these containers is variable depending on the gas phase

pressure and the saturation temperature of the liquid.

Vaporizer

Performance Graph

Liquid Withdrawal

CAUTION:

To avoid

contamination, close

the LIQUID valve on

an empty container

before disconnecting

the transfer line.