Notice, Warning, Operation – Campbell Hausfeld HVLP User Manual

Page 4: Maintenance, Preparation (continued)

4

Operating Instructions and Parts Manual

6. Attach the air hose quick-connect

fitting to the gun.

The quick-connect

NOTICE

fitting outer sleeve is

spring load ed and must be pulled back to

attach or remove it from the gun (See

Figure 10).

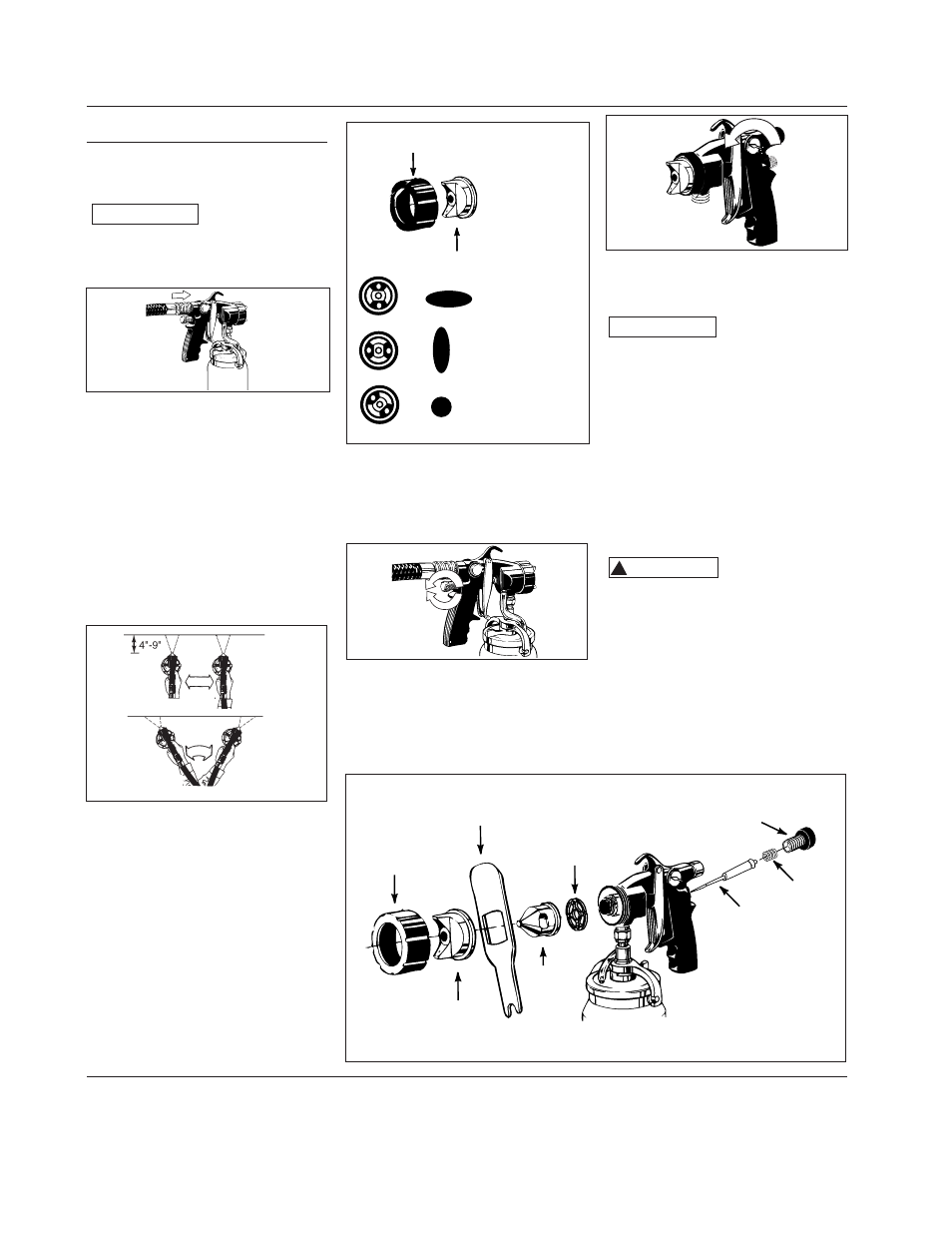

Figure 10 - Attaching The Air Hose

Operation

Always practice first. Make the gun

adjustments on a test surface such as

cardboard before spraying the project.

1. Keep the gun 4" - 9" from, and

parallel to the surface of the object

being sprayed. (See Figure 11). If

the material delivery is adjusted

for a small narrow pat tern, it may

be necessary to move as close as 2"

from the work surface.

Figure 11 - Painting Strokes

2. Move the gun in a smooth even

stroke. Begin the stroke before

pulling the trigger and continue the

stroke after releasing the trigger.

3. For best results overlap each stroke

by 25 to 50%.

4. To adjust the spray pattern “type”,

turn the air cap to the desired

pattern position (See Figure 12).

Figure 12 - Adjusting The Spray

Patterns “Type”

5. To adjust the material flow, turn the

material control knob clockwise to

decrease and coun ter clock wise to

in crease. (See Figure 13).

Figure 13 - Adjusting The Material Flow

6. For fine pattern adjustment, turn

the air flow control knob clock wise

to de crease and counterclockwise to

in crease air flow (See Figure 14).

IN

CREASE

D

EC

R E AS

E

Figure 14 - Fine Pattern Adjustment

Reducing the air flow also reduces

overspray.

The turbine air

NOTICE

hose can be used to

blow-dry those areas that are too heavily

coated, or slow in drying.

The air from the turbine is warm as a

result of normal operation. This can

affect the finish quality on hot dry

days due to premature drying of some

coatings such as lacquer. Retarding

agents can be added to the material

to resolve this condition. Consult the

material supplier for the proper re tard-

ing agent, and mixing procedures.

Maintenance

CLEANING

Make sure the room

!

WARNING

is well ventilated

when using solvents. Dispose of all

materials properly, in ac cor dance with all

local reg u la tions.

1. Remove the material control knob,

spring, and nee dle. (Pull the trigger

to help remove the needle). NOTICE:

Removing the needle prior to

removing the nozzle will prevent

needle damage.

2. Using the sup

plied wrench, un screw

and re move the re tain er ring, nozzle,

and airflow ring (See Figure 15).

IN

CREASE

Right

Wrong

=

=

=

Retaining

Ring

Spring

Horizontal Pattern

Use up and down

strokes

Vertical Pattern

Use right to left or

left to right strokes

Round Pattern

Stroke in any

direction

Figure 15 - Preparation For Cleaning

Retaining ring

Wrench

Air

Flow

Ring

Nozzle

Air Cap

Needle

Spring

Material Flow

Control Knob

Preparation (continued)

www.chpower.com