Notice, Preparation, Setup (continued) – Campbell Hausfeld HVLP User Manual

Page 3

3

Operating Instructions and Parts Manual

6. Install the appropriate needle/nozzle

assembly se lect ed for the material to

be sprayed (Fig. 2, 3 & 4 ).

7. Reassemble the needle assembly,

spring, ma te ri al con trol knob,

nozzle, air cap, and retainer ring.

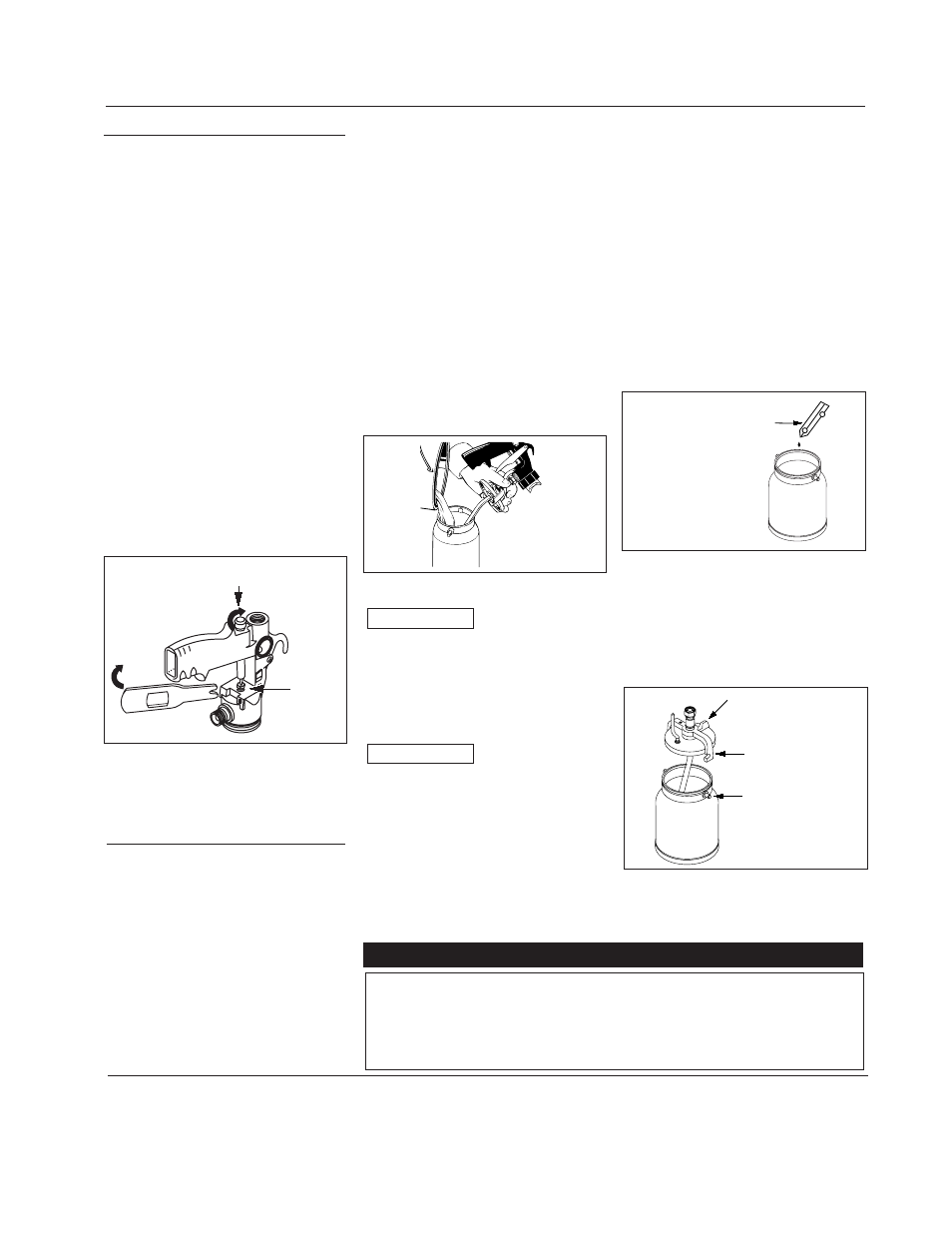

ADJUSTING PACKING

Occasionally the packing nut, located

forward of the trigger as sem bly, will

require adjustment. The pack ing nut

will also require adjustment when the

needle/nozzle assembly is changed

(Figure 6).

1. Turn the material flow control knob

clockwise at least 3/4 of the way in.

2. Tighten the packing nut with

the wrench by turning the nut

clockwise until the needle will

not return to the closed position

when the trigger is released. Do

not overtighten the packing nut.

To properly adjust the packing, the

nut should be tightened no further

than is required to stop the needle

from returning. (See Figure 6).

Figure 6 - Adjusting The Packing Nut

3. Loosen the packing nut (approx.

1/4 turn) until the needle returns

freely to the closed position.

Preparation

PREPARING TO SPRAY

Some manufacturers specify that their

ma te ri als should not be thinned. In

general, these in struc tions apply only

when a brush or roller is used. It may

be necessary to thin these materials if

they are to be sprayed. Check with the

paint supplier for specific details when

pur chas ing the material to be sprayed.

Be sure to stir the material thoroughly

after adding a thinning agent, and

before checking the vis cos i ty. Fail ure to

properly mix the material results in a

poor finish.

NOTICE: Some latex finishes are very

thick and require the greatest amount

of thinning and mixing. A latex paint

conditioner can be added to the

paint to improve spray performance

(available at most home centers).

1. Strain paint before spraying.

Unstrained paint may affect

material flow and spray pattern.

When spray ing thin materials such

as lacquer or stains, consult with

the material supplier for the proper

strainer mesh number.

2. Pour material into the paint cup.

Fill the material cup only 1/2 to 3/4

full if thinning of the material is

required. (See Figure 7). Refer to

the material chart below for proper

thinning instructions.

Figure 7 - Filling The Paint Cup

Follow the

NOTICE

material

manufacturer’s rec om men da tion for the

proper thinning solvent.

3. Using the following procedure,

check the vis cos i ty of the material

before locking the gun onto the

material cup (Figure 8).

The viscosity stick

NOTICE

is located in the

storage compartment.

a. Dip the viscosity stick into the

material. As the viscosity stick is

removed from the material, the

material will initially run off the stick

as a stream. The material stream will

break up and begin to drip after

running off the stick for a short time.

b. Estimate the time interval be tween

each of the first three drips of

material. The time between the

first three drips of material will vary

de pend ing on the thickness or the

“viscosity” of the material.

c. The material is adequately thinned if

the first three drips from the viscosity

stick are about one second apart.

d. As a general rule, if the time

between drips is more than one

second, the material is too thick.

Add thinning agent, stir thoroughly

and repeat the above pro ce dure

until the proper viscosity is attained.

Figure 8 - Viscosity Stick

4. To tighten and lock the cup, place

the retainer arms securely around

the retaining pins on the paint cup.

5. Move the locking lever clockwise to

the locked po si tion. (See Figure 9).

Figure 9 - Locking The Cup

Acrylics .............................................................. Follow Manufacturer’s Instructions

Stains ......................................................................................No Thinning Required

Clear Sealers ...........................................................................No Thinning Required

Lacquers ........................................................... Follow Manufacturer’s In struc tions

Oil-Base Paint ............................................................................................... 10 - 40%

Latex Paints .................................................................................................. 15 - 20%

MATERIAL

PERCENT

REDUCED

Viscosity Stick (Located

Inside The Storage

Compartment)

Material Flow

Control Knob

Packing

Nut

Tighten

Locking Lever

Retaining Pin

Retaining Arm

Setup (continued)

www.chpower.com