Uni-max, Lms-uni), Installation guide – LaserMax LMS-UNI-MAX RED User Manual

Page 2: Warning

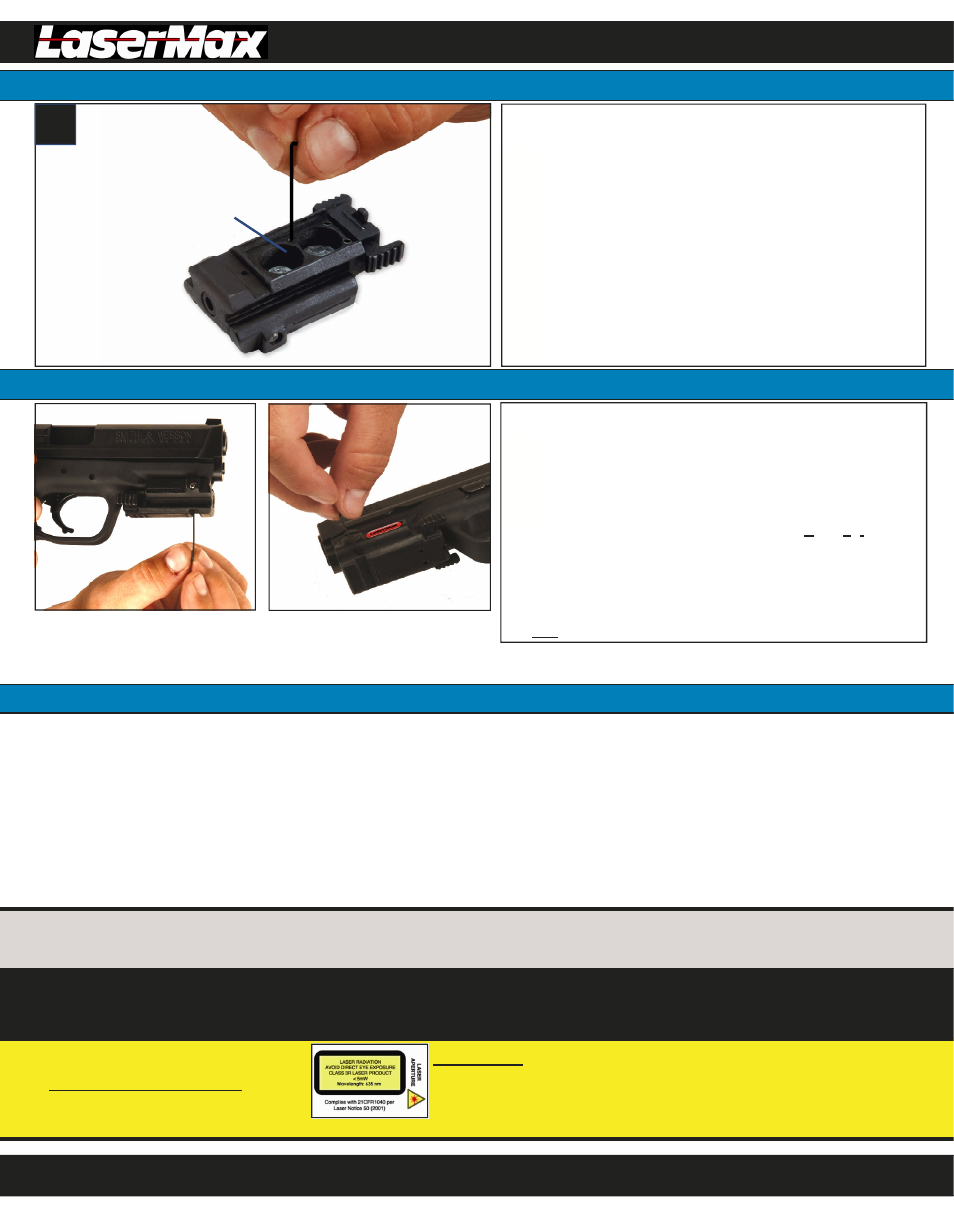

To sight in your laser, insert the Adjustment Tool into

one of the small alignment ports on the outside of the

Laser Housing.

Fine tune your laser alignment by slowly turning the

Adjustment Tool, then checking your laser position

against your fixed sights and your POI(Point of Impact).

The Uni-Max comes factory set for a modulated (pulsed) beam for

higher visibility. To change to a continuous wave (steady on) beam,

follow these simple steps:

g

installation guide

Uni-Max

®

(LMS-UNI)

Changing The Laser Mode

1.800.527.3703

installation guide

1.800.527.3703

01785-0-19

REV F 12/10

Remove the Battery Cover.

Insert Adjustment Tool into the beam selection port.

(See Figure g)

Slowly turn the Adjustment Tool clockwise until you feel

resistance. Do not over tighten.

Reassemble and confirm that your beam is now

continuous wave (steady on).

To return to the modulated (pulsed) laser mode, simply

insert Adjustment Tool into the beam selection port and

make three counterclockwise turns. Do not remove the

set screw from the beam selection port.

Beam Selection Port

(do not remove internal set screw)

You can easily fine tune your laser to accommodate any weapon

platform, type of ammunition or shooting distance.

Limited Warranty

LASERMAX, INC.

3495 WINTON PLACE

ROCHESTER, NY 14623 USA

Patent No. 7,421,818; other patents pending

LMS-UNI

RED/ORANGE LASER SIGHT

CLASS 3R VISIBLE LASER PRODUCT

Output: <5 mW

Wavelength: 635 nm

Complies with 21CFR1040 per laser notice 50 (2001)

Reminder:

Aiming laser beam at moving vehicles including boats, aircraft, trains, and construction equipment may be illegal. Check current applicable laws and follow them accordingly.

WARNING:

Avoid direct exposure

to beam.

Registration of your product is required in order to receive warranty service. Log on to www.lasermax.com to

fill out the registration form.

LaserMax, Inc. laser products, except expendable parts, are warranted to be free from defects in material and workmanship for a period of one year from the date of purchase submitted

through warranty registration at www.lasermax.com. Expendable parts shall be defined as batteries, springs, and replaceable plastic parts. Expendable parts of some models have definite

life expectancies. They should be replaced as recommended to protect the laser and preserve your warranty. This warranty shall benefit, and may be enforced only by the initial purchaser

of the laser system and is not transferable. Warranty is limited solely to repairing or replacing the part(s), at the discretion of LaserMax, Inc.; which proves to be defective during the war-

ranty period. Parts and equipment replaced under warranty will not be returned. Parts and equipment repaired under warranty will be covered for the remaining portion of the original war-

ranty period. This warranty does not apply to equipment or parts which upon inspection by LaserMax, Inc. are determined by LaserMax, Inc. to have become defective or unworkable due

to abuse, mishandling, misuse, alteration, negligence, improper installation or maintenance, damage resulting from use of springs not supplied with laser, damage resulting from repair or

attempted repair by anyone other than LaserMax, Inc. or a repair facility authorized by LaserMax, Inc., or other causes beyond the control of LaserMax, Inc. All returns must have factory

labeling present and legible. All returns require a return authorization number available from our Warranty Department at 1-800-LASER-03. The hours of operation are from 9 a.m. to 5 p.m.

EST, Monday through Friday.

LASERMAX, INC. DISCLAIMS LIABILITY FOR INCIDENTAL AND CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY. ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO THE LASERMAX, INC. LASER PRODUCT IS FOR A PERIOD OF ONE YEAR FROM DATE OF

PURCHASE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

Important:

This alignment should be done at a minimum distance

of 10 yards. A one-quarter (1/4) turn equals approximately 3 inches

at 10 yards

Warning:

Do not turn Adjustment Tool more than one complete

turn from factory position. This may cause damage to the Uni-Max

and may void your warranty.

The hole at the side adjusts windage

(horizontal alignment). A clockwise turn

(front, to top, to bottom) shifts laser to

the left.

The hole at the bottom adjusts elevation

(vertical alignment). A clockwise turn

(left side, to front, to right side of fire-

arm) shifts laser down.

SPARE PARTS LIST:

LMS-UNI-RG:

Removable Rail Grip

LMS-UNI-CS:

Clamping Screw (Part: B)

-includes spring

Battery Cover (Part: C),

Flat Head Screw (2)(Part: D),

Adjustment Tool (Part: F)

LMS-UNI-AS:

Activation Switch (Part: G)

LMS-2X357:

Batteries: 357(2) (Part: E)

LMS-UNI-SKN:

(Service Kit)

Aligning The Laser For POA/POI

NOTE:

When installing Uni-Max for the first time, a slight shift in alignment may be

noticed after firing, due to settling. Recheck alignment after firing a few magazines and

readjust if necessary.

ACCESSORIES:

LMS-UNI-MAS-10:

Momentary Activation Switch (10” Cord)

LMS-ADP-SHOTGUN:

Rail Adapter for 1” shotgun mag tube

LMS-HKADP-C:

Rail Adapter for H&K USP Compact

LMS-UNI-MAS-6:

Momentary Activation Switch (6” Cord)

LMS-ADP-SIGMA:

Rail Adapter for S&W Sigma Series

LMS-HKADP-F:

Rail Adapter for H&K USP Full Size