FASS T F17 200G User Manual

Page 18

H.

Disconnect both factory return lines from the factory lift pump (refer to

diagram at the beginning of step 2). Insert DB-4646 into each return

line fitting until you hear a click and tabs lock.

G.

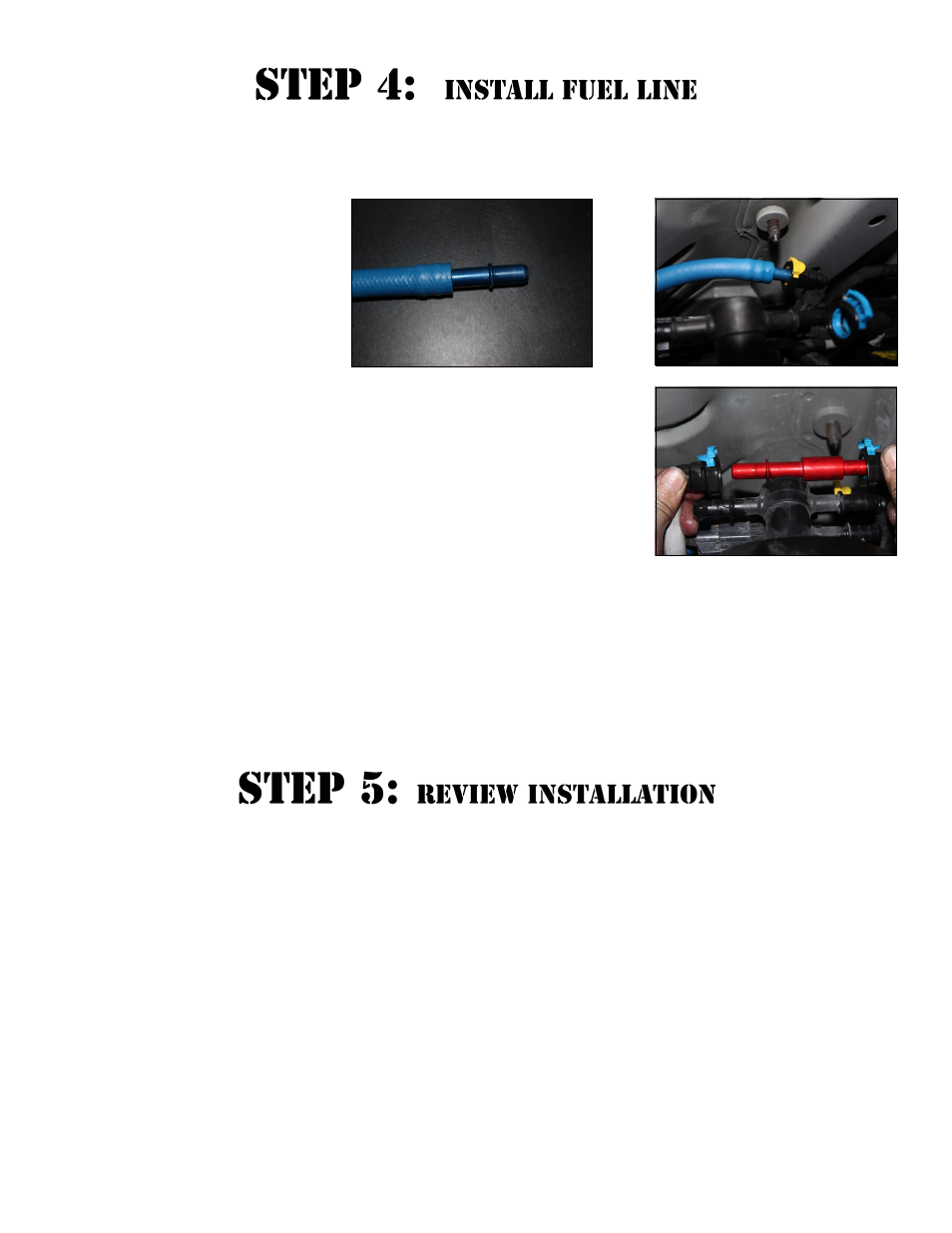

Measure fuel line from the FASS to the factory feed fitting. Cut and insert a PLB-1212 using oil. Oil

the PLB and slide into the yellow-clipped factory feed fitting until you hear a click. Push down the

locking tab.

I.

Clean and cap off the factory return ports with the two RVC-38 caps. Clean and cap off the factory

feed port with the RVC-12 cap. Seal factory electrical connection with di-electric grease or similar to

prevent corrosion.

Blow out any open lines/cover any open ports

Bolts and fasteners properly tightened?

Electrical harness and fuel lines secured and properly tightened? Reconnect the battery.

Has the system been primed?

1. Turn key to the ignition position, turning on the FASS pump for 15 sec..

2. Crank engine and allow to run for at least 1 minute.

Check for leaks.

Start the engine

Recheck all fluid and filter connections for leaks

This pump comes with a 1 Year Manufacturer’s Warranty based on the date it has been manufactured.

To receive your extended Lifetime Warranty, you have 30 days from date of purchase to send the com-

pleted warranty information along with a copy of the purchase receipt in to Diesel Performance Prod-

ucts, Inc. Att: Warranty 16240 Hwy O Suite B Marthasville, MO 63357

Note: Secure all fuel lines with cable ties. Cable ties are an economical way to prevent the possibility

of problems occurring!The factory suction line can be capped off or removed from the truck. The

openings on the filter and tank will need to be capped off to keep debris from getting into lines or

canister.