FASS T F17 200G User Manual

Page 12

NOTE: Hose clamps are not recommended for push lock fittings.

They will hold up to 300psi! Use oil on fittings and inside fuel

line when installing Push-Lok fittings.

L.

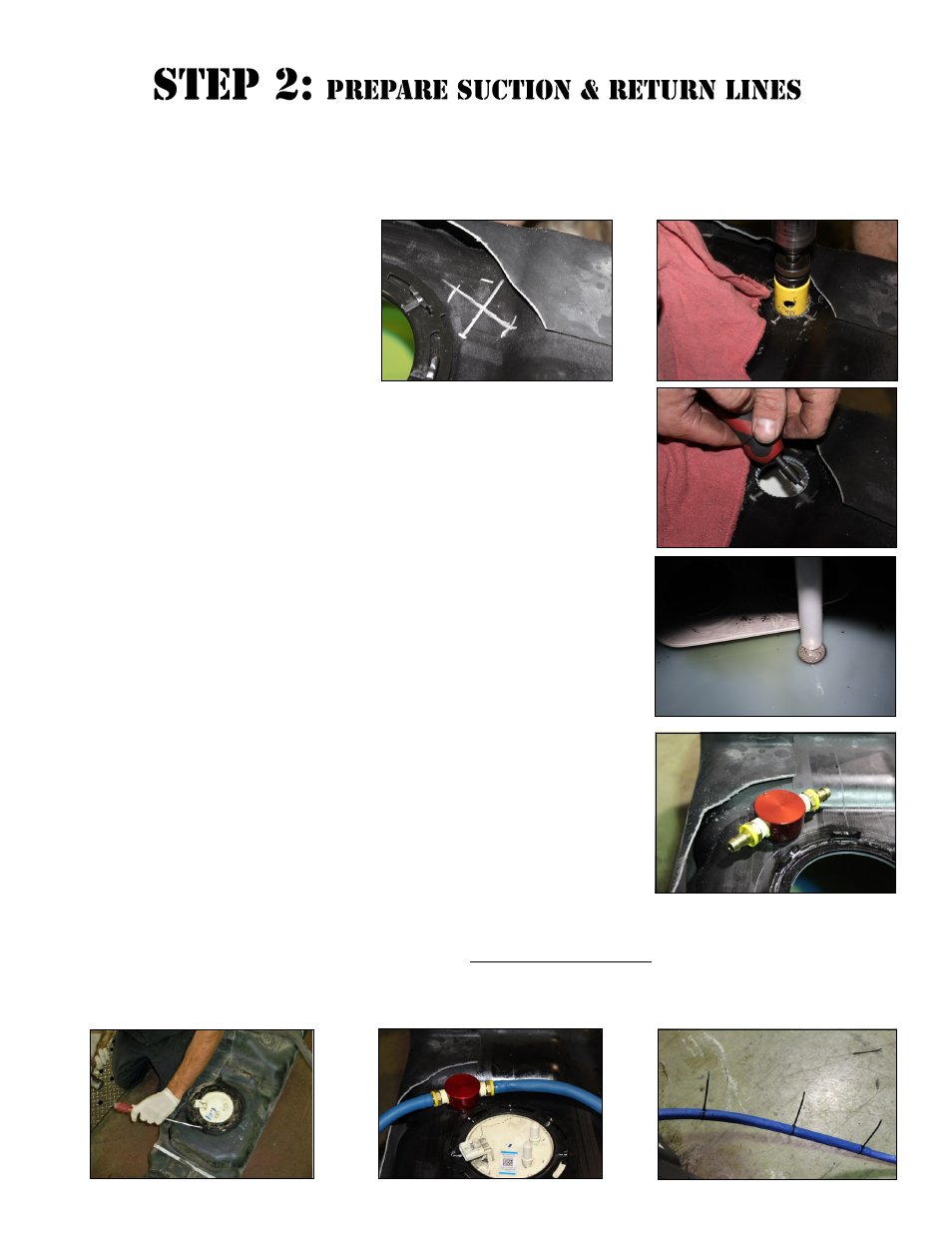

De-burr hole and check for fit.

M.

Place the bulk head assembly into the drilled hole, take measurements

so the bottom of the suction tube is only 1/8” (no more than 2 quarters

stacked) from the bottom of the fuel tank. Using a razor knife, make

multiple cuts to insure proper length, it is easy to shave the suction

tube with the razor. It is more efficient to cut the tube too long and

then correct to proper length than it would be to cut too short.

O.

Carefully reinstall install pick up module making sure the leveling arm is not obstructed by the suction

tube. Reinstall factory lock ring. Push one end of the 1/2” fuel line onto ‘R’ port of suction tube assy. &

one end of the 5/8” fuel line onto the ‘S’ port. Do not cut at this time. Cover the return line with spare

tubing or similar to protect fuel line from the trimmed fiberglass shell. Reinstall fuel tank making sure

to reconnect factory suction line, factory return line, and electrical connections. Route FASS fuel line to

prevent pinching. Torque hanger bolts to factory specifications.

N.

Install Bulkhead with lock washer and nut. Tighten nut securely with

a 1-7/8” socket or wrench. Make sure the fittings are unobstructed.

K.

Once location has been established, double check! Make sure the fuel line and fittings will clear the

trimmed protective shell. Mark location and drill 1 3/8” hole with hole saw. Hold a cup or catch can

inside the tank while drilling to catch any debris. Place a rag over the opening to prevent tank contami-

nation. Double check for debris around the ring and inside tank.