Installation, Application 1, Application 2 – Dynalco SW-100 Speed Switch User Manual

Page 9: Troubleshooting

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to

standard DIN style mounting rails, including G profile rail according to

EN50035 - G32 , and top hat (T) profile rail according to EN50022 - 35 x

7.5 and 35 x 15. The unit should be installed in a location that does not

exceed the maximum operating temperature and provides good air

circulation. Placing the unit near devices that generate excessive heat

should be avoided.

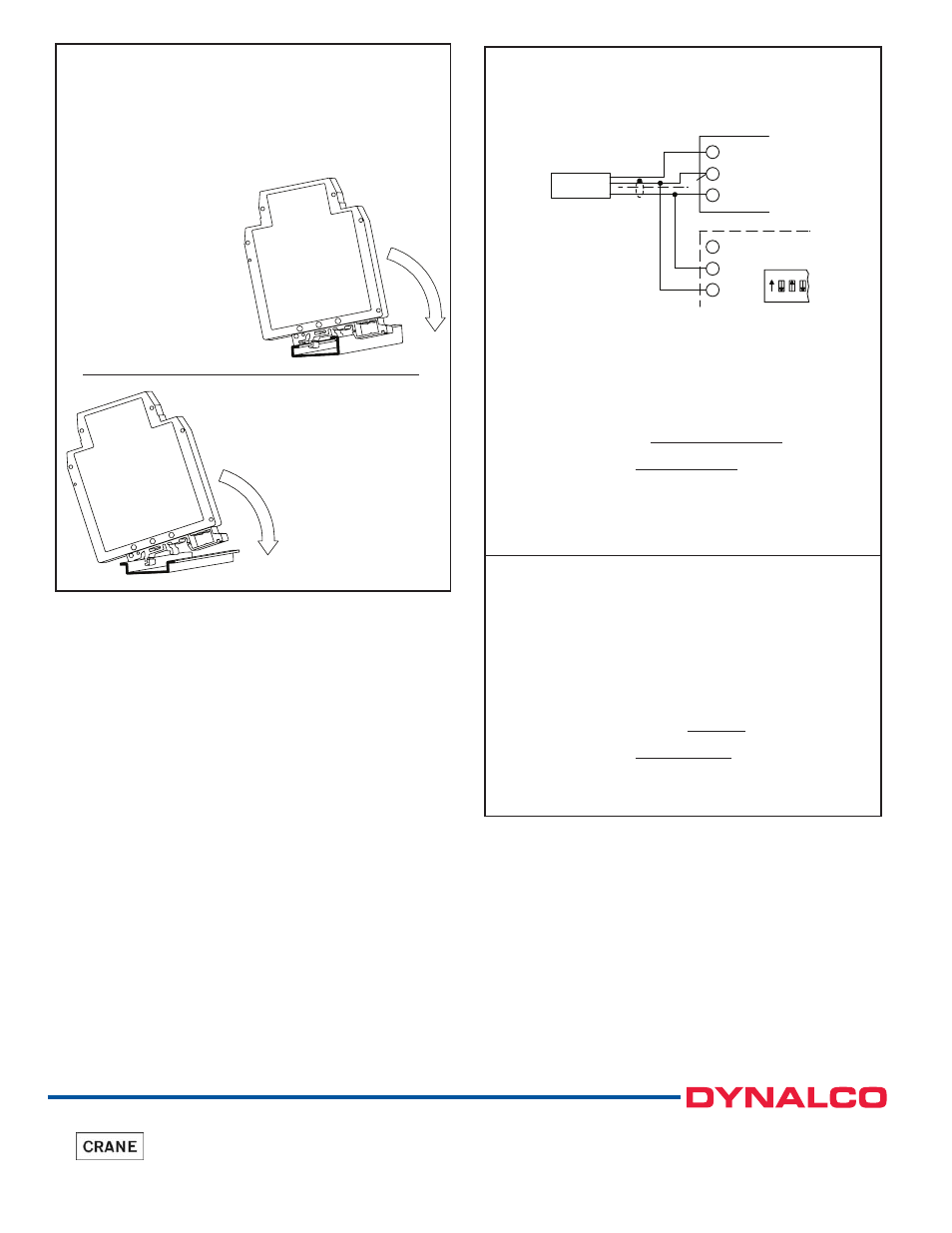

G Rail Installation

To install the SW-100 on a “G”

style DIN rail, angle the module

so that the upper groove of the

“foot” catches under the lip of the

top rail. Push the module toward

the rail until it snaps into place. To

remove a module from the rail,

push up on the bottom of the

module while pulling out away

from the rail.

T Rail Installation

To install the SW-100 on a

“T” style rail, angle the

module so that the top groove

of the “foot” is located over

the lip of the top rail. Push the

module toward the rail until it

snaps into place. To remove a

module from the rail, insert a

screwdriver into the slot on the

bottom of the “foot”, and pry

upwards on the module until it

releases from the rail.

APPLICATION 1

An APLR is connected to an LMPC (logic magnetic pickup) that is

sensing the speed of a 60 tooth gear attached to a shaft. The shaft speed

should not exceed 2000 RPM.

The SW-100 is placed in parallel with the APLR to activate an alarm

when an overspeed condition is detected, and to turn off the alarm when the

speed returns to normal. The Mode of Operation is set for Mode #1

(overspeed trip, automatic release upon return to normal).

To set the value of the alarm, either apply the maximum input signal as

described in Section 2.0 or determine the Trip Frequency using the

following formula:

Trip Freq. = units/measure x pulses/unit

seconds/measure

Trip Freq. = 2000 RPM x 60 PPR = 2000 Hz

60 sec

Set the Trip Frequency with the rotary switch for 2000 Hz.

With Trip point Offset set at 0.00% (No Offset) and Trip Point Hysteresis

set at 0.25%; activation of the relay occurs at 2000 Hz, and release occurs

at 1995 Hz.

APPLICATION 2

The SW-100 can be used in a speed monitoring system to detect when the

system drops below setpoint.

The SW-100 is wired to a PSAC (inductive proximity sensor) that is

sensing a key way on the shaft of a motor. The motor is turning at 1750 RPM.

When the speed of the motor drops below 1250 RPM, the SW-100 latches

the output until the user resets the output with an external push button.

The mode of operation of the SW-100 is set for 5 (UNDERSPEED

Latched trip, release only after Alarm Reset pulled to common). Determine

the Trip Frequency using the following formula:

Trip Freq. = RPM x PPR

60

Trip Freq. = 1250 RPM x 1 PPR = 20.83 Hz.

60 sec.

Set the Trip Frequency with the rotary switch for 20.83 Hz.

TROUBLESHOOTING

For further technical assistance, contact Dynalco at thenumber below.

Toll Free 800.368.6666 (US & Canada)

Main 954.739.4300 • Fax 954.484.3376 • www.dynalco.com

3690 NW 53rd Street, Ft. Lauderdale, FL 33309 USA

A division of Crane Co.

SNK

LOGIC

SRC

ON 1 2 3

7

8

9

+12V

INPUT

COMM.

COMM.

INPUT

+12V

8

9

7

APLR

LMPC

SW-100