Dynalco SW-100 Speed Switch User Manual

Page 5

4

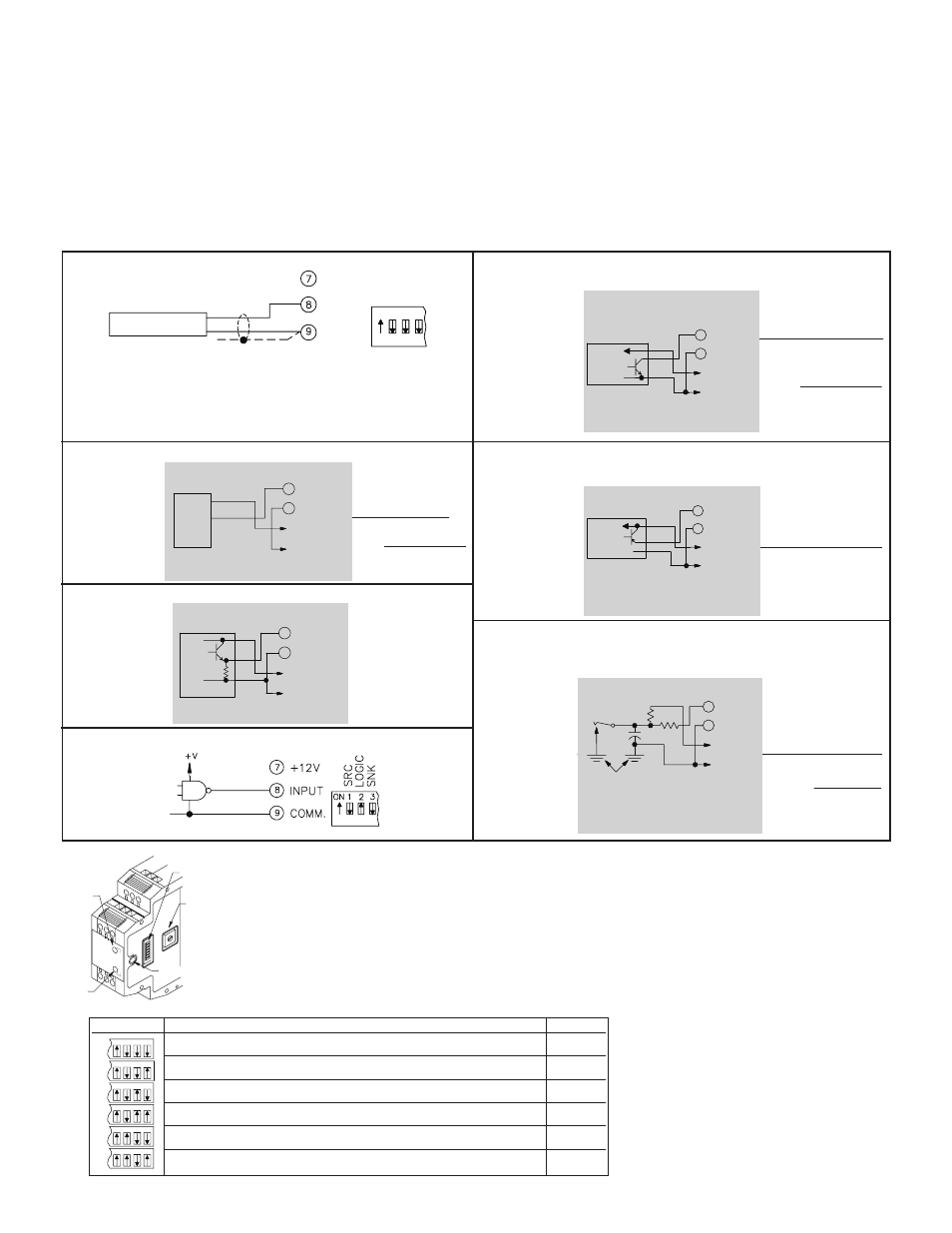

CONNECTIONS & CONFIGURATION SWITCH SET-UP FOR VARIOUS SENSOR OUTPUTS

Note: Separate power supplies must be used for sensor power and input power to maintain the isolation breakdown voltage specification. If isolation between power

and input is not needed, then a single supply can be used for both unit and sensor power.

The SW-100 Speed Switch uses a comparator amplifier connected as a

Schmidt trigger circuit to convert the input wave form into the pulse form

required for proper circuit operation. Three set-up switches are used to configure

the input circuit to accept signals from a wide variety of sources, as follows:

S1 - ON: Connects a 1 K

Ω pull-down resistor for sensors with sourcing outputs.

(Maximum sensor output current is 24 mA @ 24 VDC output.)

S2 - ON: For logic level signals, sets the input bias levels to V

IL

= 2.5 V,

V

IH

= 3.0 V.

OFF: For increased sensitivity when used with magnetic pickups, sets the

input bias levels to V

IL

= 0.25 V, V

IH

= 0.75 V.

S3 - ON: Connects a 3.9 K

Ω pull-up resistor for sensors with current sinking

output. (Max. sensor current = 3 mA.)

INPUT CIRCUITS, SENSOR CONNECTIONS AND CONFIGURATION SWITCH SET-UP

CONFIGURING THE SW-100

Upon entry to a set-up parameter, the Input LED blinks the current numerical value of a setting at a 1 Hz rate. A setting

of “1” is indicated by one blink (½ sec on, ½ sec off), through a setting of “9”, which is indicated by nine blinks. A setting

of “0” is indicated by a single short flash (40 msec on, 1 sec off). After the entire value is indicated, the SW-100 pauses two

seconds and repeats the value.

During entry of a new value, if the Mode switch (S4) or any of the CFG DIP switch positions are changed before the push

button is pressed, the SW-100 aborts the entry process and retains the previous setting.

To begin set-up, place DIP switch 4 to the on (up) position. DIP switches 5, 6, and 7 access unit configuration settings.

Note: To return to normal operation,

place DIP switch 4 in the down

(RUN) position.

( ) Indicates Configuration Section

DIP SWITCH DESCRIPTION

SECTION

Operating Mode

(1.0)

Set Trip Frequency Using an Input Signal or Frequency Generator

(2.0)

Set Trip Frequency Using the Rotary Switch

(3.0)

Set Minimum Response Time

(4.0)

Set Relay Trip Point

(5.0)

Set Relay Release Point

(6.0)

NPN O.C.

OUTPUT

SENSOR

WHT

BLK

RED

COMM.

INPUT

EXT. VDC+

EXT. VDC-

8

9

*

PNP O.C.

OUTPUT

SENSOR

OUTPUT

COMM.

+12V

COMM.

INPUT

EXT. VDC+

EXT. VDC-

8

9

*

+12V

INPUT

COMM.

SRC LOGIC SNK

MAGNETIC PICKUP

ON1 2 3

COMM.

INPUT

EXT. VDC+

EXT. VDC-

8

9

1.8K

CONTACT

MACHINE GROUND

10µF

1.8K

COMM.

INPUT

EXT. VDC+

EXT. VDC-

8

9

*

C

B

A

OUTPUT

-EF

SENSOR

COMM.

INPUT

EXT. VDC+

EXT. VDC-

8

9

*

MODELS

PSA-1

SENSOR

PSA-2

R

BLU

BLK OR BRN

*

Check sensor power requirements before

wiring.

*

Check sensor power requirements before

wiring.

*

Check sensor power requirements before

wiring.

*

Check sensor power requirements before

wiring.

*

Check sensor power requirements before

wiring.

MAGNETIC PICKUPS

RECOMMENDED RULES FOR MAGNETIC PICKUP CONNECTIONS

1. Connect the shield to the common Terminal “9” at the input of the SW-. DO NOT

connect the shield at the pickup end. Leave the shield “open” at the pickup and insulate

the exposed shield to prevent electrical contact with the frame or case. (Shielded cable,

supplied on some magnetic pickups, has open shield on pickup end.)

2-WIRE PROXIMITY SENSORS - DC

OLDER STYLE SENSORS WITH -EF OUTPUT - DC

INPUT FROM CMOS OR TTL

SENSORS WITH CURRENT SINK OUTPUT (NPN O.C.) - DC

SENSORS WITH CURRENT SOURCE OUTPUT (PNP O.C.) - DC

SWITCH CONTACT INPUT - DC

GREEN

LED

SWITCHES

ROTARY

PUSHBUTTON

SWITCH

INPUT

LED

OUTPUT

RED

DIP

OUT

IN STA

TUS

4 5 6 7

5

4

7

6

5

4

7

6

5

4

7

6

5

4

7

6

5

4

7

6