Drucker Diagnostics Model 642E Centrifuge User Manual

Page 2

Page 2

Model Description:

The Model 642E is a continuous-duty, electronically-controlled horizontal

centrifuge with a lid safety interlock system. The unit is controlled by an

electronic push–button timer that has been preset for ten (10) minutes, for

precise spin times and ease of use. Samples can be safely viewed through

the transparent lid. Entry into the machine is restricted during operation by the

safety interlock system. The Model 642E features a lighted control panel that

displays the status of the machine, easily viewable from a distance.

For warranty information, turn to page 12.

Intended Use:

General purpose laboratory centrifuge for sample separation.

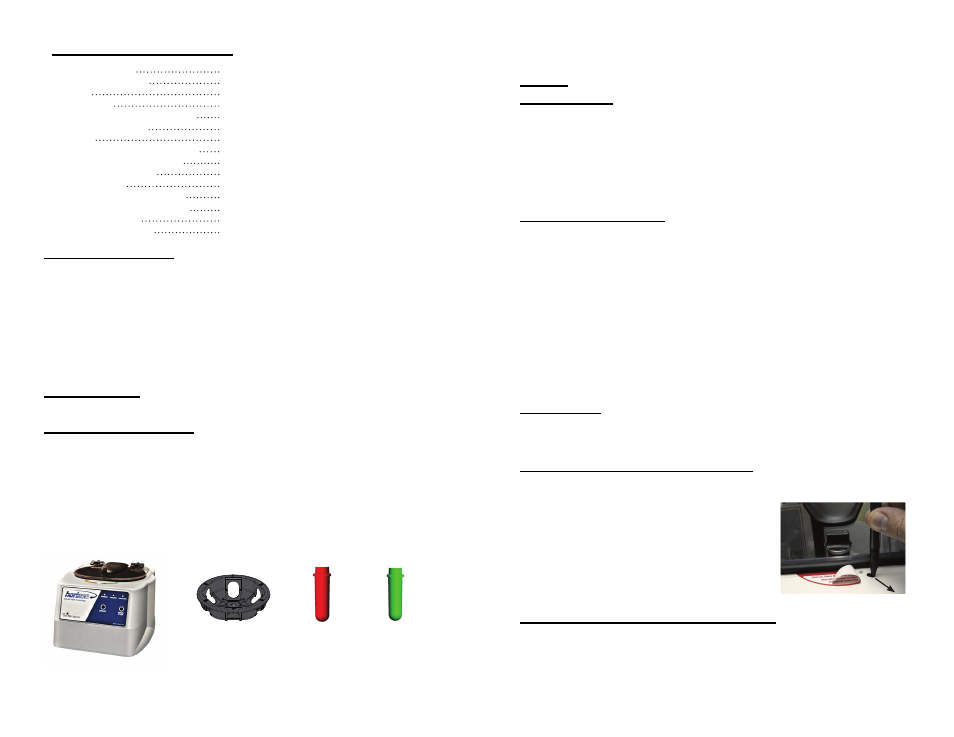

Supplied Equipment*:

The following items come standard with each Model 642E centrifuge:

1. One (1) six–place horizontal rotor

2. Six (6) 100 mm tube holders

3. Six (6) 75 mm tube holders

4. Two (2) 13 x 75 mm inserts

p/n 7713064 (Not shown below)

5. Two (2) 13 x 100 mm inserts

p/n 7713066 (Not shown below)

6. Two (2) 0.5 to 1 mL tube adapters p/n 7713068 (Not shown below)

7. Two (2) 1.5 to 2 mL tube adapters p/n 7713065 (Not shown below)

WARNING: For the safety of both the opera-

tor and service personnel, care should be

taken when using this centrifuge if handling

substances that are known to be toxic,

radioactive or contaminated with pathogenic

microorganisms. When Risk Group II ma-

terials are used, (as identified in the World

Health Organization “Laboratory Bio-Safety

Manual”), a Bio-Seal should be employed.

The Bio-Seal accessory for the model 642

tube holders is the non-aerosol shield cap,

p/n 7713011. In the event that materials of a

higher risk group are being used, more than

one level of protection must be provided.

The use of flammable or explosive materials

as well as those materials which have a

vigorous chemical reaction is prohibited.

For your safety and the durability of your

machine, never transport or store centrifuge

with tube holders inside machine.

Table of Contents

Model Description

pg. 2

Supplied Equipment

pg. 2

Features

pg. 3

Specifications

pg. 3

Setup Location and Procedure

pg. 4

Front Panel Controls

pg. 5

Operation

pg. 6

Rotor Removal and Installation

pg. 7

Tube Holder Configurations

pg. 8

Care and Maintenance

pg. 9

Troubleshooting

pg. 10

Safety, Emergency Lid Unlock

pg. 11

Calibration and Ground Testing

pg. 11

Replacement Parts

pg. 12

Available Accessories

pg. 12

p/n

7786061

p/n

7713031

p/n 7713033

Page 11

1.

2.

x6

* The rotor and rotor accessories are rated for a rotation frequency of 4,000 RPM.

3.

x6

Safety:

Lid Safety Switch: The Model 642E lid is secured to the top of the cabinet by

a latching knob and pawl system. When the knob is rotated clockwise, the pawl

grips the underside of the cabinet opening and prevents the lid from opening.

A mechanical stop positions the pawl and prevents it from rotating completely.

When rotated to the stop position, the pawl makes contact with a micro–switch

mounted underneath the cabinet top. The lid safety switch prevents the centri-

fuge from operating while the lid is open. An indicator light on the front of the

machine will light up when the lid has been latched properly.

Lid Safety Interlock System: In addition to the Lid Safety Switch, the Model

642E has a true “0 RPM” lid locking system. The lid safety interlock system

keeps the lid locked at all times, (even during power failure), and requires that

the rotor be at rest in order to unlock the lid. The centrifuge will not allow entry

into the rotor chamber unless the centrifuge has power and the rotor is stopped.

To open the lid, make sure that the centrifuge is plugged in and, with the rotor

stopped, press the ‘OPEN / STOP’ button.

Note: After the centrifuge has started spinning, it may be possible to rotate

the lid knob enough to cause the pawl to lose contact with the lid safety

switch. If this happens, the centrifuge motor may lose power, but the lid

will still remain locked. If the knob is accidentally moved and this situation

should occur, rotate the knob fully clockwise to its stop position and the

centrifuge will resume operation.

Circuit Breaker: The Model 642E is protected with a 4 Amp circuit breaker lo-

cated at the rear of the machine mounted to the base. Any electrical short circuit

will cause the breaker to cut power to the machine.

Emergency Rotor Chamber Entry:

In the event of power failure, it may be impossible to unlock the lid by

conventional means. In this case, entry into the rotor

chamber may be made by removing the latch label

and using a pen to manually disengage the locking

mechanism (see photo). Pull the mechanism towards

the control panel and then unlatch and open the lid.

If the unit is damaged, contact your authorized dealer

or The Drucker Company.

Calibration and Earth Ground Testing:

It is recommended that the top speed, ground continuity and line leakage be

tested every two years for continued safe operation. Contact The Drucker Com-

pany for further information or testing availability.

The Horizon Model 642E complies with all requirements of

UL standard 61010A-1, 61010A-2-20; Can/CSA C22.2 No’s

1010.1; 1010.2.20.

For Optional Accessories see the last page of this manual

B

B

C

C

D

D