Balanced loads – Drucker Diagnostics Model 614B Centrifuge User Manual

Page 4

Setup Location:

1. Unpack the centrifuge and verify that all of the supplied equipment is present.

2. Choose a setup location which meets the following criteria:

a) A bench top clearance height of 20” is required in order to open the lid.

b) The clearance envelope is the space around the centrifuge which is

required for safety. Choose a setup location which will allow for a

clearance envelope of at least 24” x 24”, (with the centrifuge at the center).

No person or hazardous material shall be permitted in the clearance

envelope during operation. The operator time within the envelope shall

be limited to the time necessary for loading, unloading and centrifuge

operation only.

c) Proper ventilation is necessary to prevent the overheating of samples as

well as premature failure of the centrifuge. Choose an area which will

allow unencumbered air flow.

d) The centrifuge is designed to secure to the operating surface by four

suction feet. No adjustment is necessary for leveling the centrifuge,

however, the surface should be flat and level.

e)

Be sure the outlet is always within reach as the line cord is the

means

of

emergency

disconnection!

Initial Setup Procedure:

If any problems are found during the initial setup procedure, refer

to the troubleshooting section on page 8. For further assistance,

contact The Drucker Company at

814-342-6205 or

814-692-7661

.

1. Plug the centrifuge in to an approved electrical outlet. For electrical safety,

the unit must always be properly grounded.

2. Turn the latch counter–clockwise and open the lid.

3. Spin the rotor by hand; check for free and level rotation.

4. Close the lid. Rotate the lid knob clockwise to its complete stop position.

5. Turn the centrifuge on by turning the timer to 10 minutes.

6. Listen to the centrifuge. A smooth whirring sound should be heard.

After the centrifuge has passed this procedure it is ready for operation.

Page 4

BALANCED LOADS

Your centrifuge must contain a balanced load in order to work properly.

Use the following rules when loading the rotor. Spinning balanced

loads will extend the life of the machine and produce better results.

1. Opposing tube holders must be identical and must contain the same

cushion, or none at all.

2. Opposing tube holders must be empty or loaded with equally

weighted

samples.

3. If an odd number of samples is to be spun, fill a tube with water to

match the weight of the unpaired sample and place it across from

this

sample.

Replacement Parts:

Part No.

Description

7724037

Foot, rubber

7751068

Switch, lid safety

7786047

Rotor, six–place fixed-angle

7735050

Motor, 1/30 H.P.

7722027

Timer, mechanical

7751043

Circuit Breaker

03-0-0003-0061 Front Panel Label

7760002

Power cord

7714101

Pawl, latch, lid

7714103

Knob, latch, lid

7712260

Lid

7724071

Hinge, friction

7732018

Seal, lid gasket

7732019

Seal, rotor chamber gasket

7713033

Tube holder, green, for 75mm tubes

7713031

Tube holder, red, for 100mm tubes

7713032

Tube holder, black, for 125mm tubes

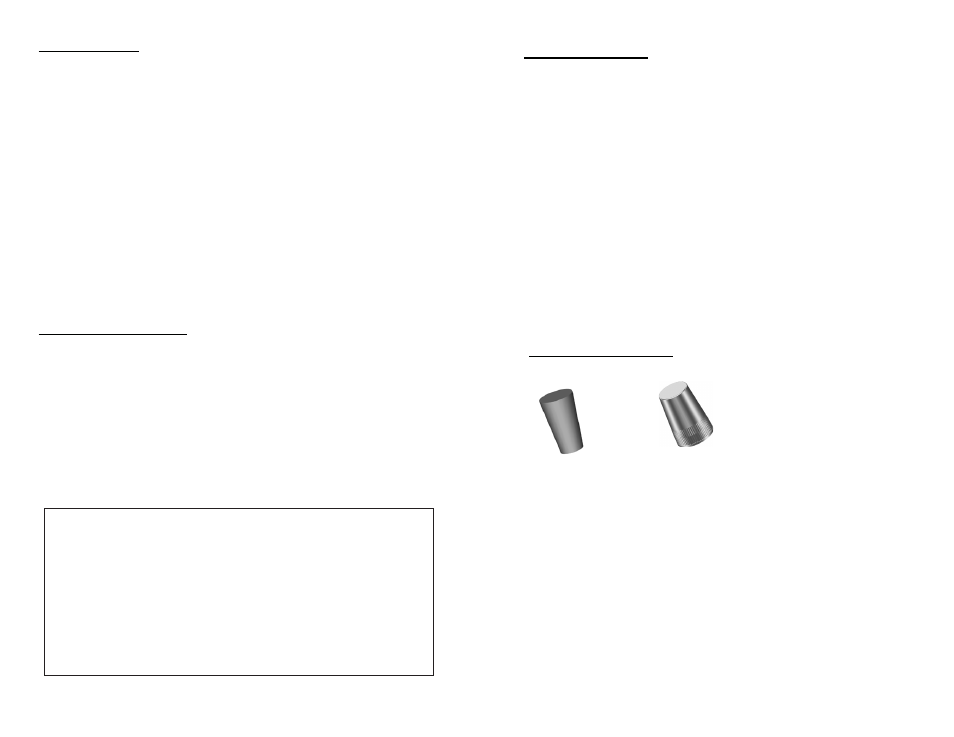

Available Accessories:

Shield

caps

p/n

7713011

1” Tube cushion

p/n 1525

Page 9