Tsf/tsfh operation, Optional equipment, Specifications – Cooper Instruments & Systems TSFM 500 Motorized Force Test Stand User Manual

Page 5

CF 141

5

32-1032 REV 1 0405

TSF/TSFH

OPERATION

1. Mount the test stand to a firm, flat, and level working surface for maximum safety and accuracy using

four 5/16 screws (not included). Use the included mounting hole drill template (vertical model only) to

accurately drill the holes. Testing can take place without securing the test stand in such a manner,

however, it is strongly recommended that the stand be secured, especially for large forces.

2. Install a force gauge onto the gauge plate with four thumbscrews. All Cooper force gauges mount

directly to the stand without adapters.

3. Install any required attachments, including grips, adapters, and other materials necessary for your

test sample. Make sure these items are set up in a secure and safe manner.

4. Begin the test by turning the hand wheel clockwise for compression or counter-clockwise for tension.

The gauge bracket’s height can be adjusted along the column. Loosen the four screws that secure the

bracket to the column, adjust to the desired height, and retighten the screws.

Note: To maintain smooth operation of the test stand, avoid overloads and repetitive shock loads.

OPTIONAL EQUIPMENT

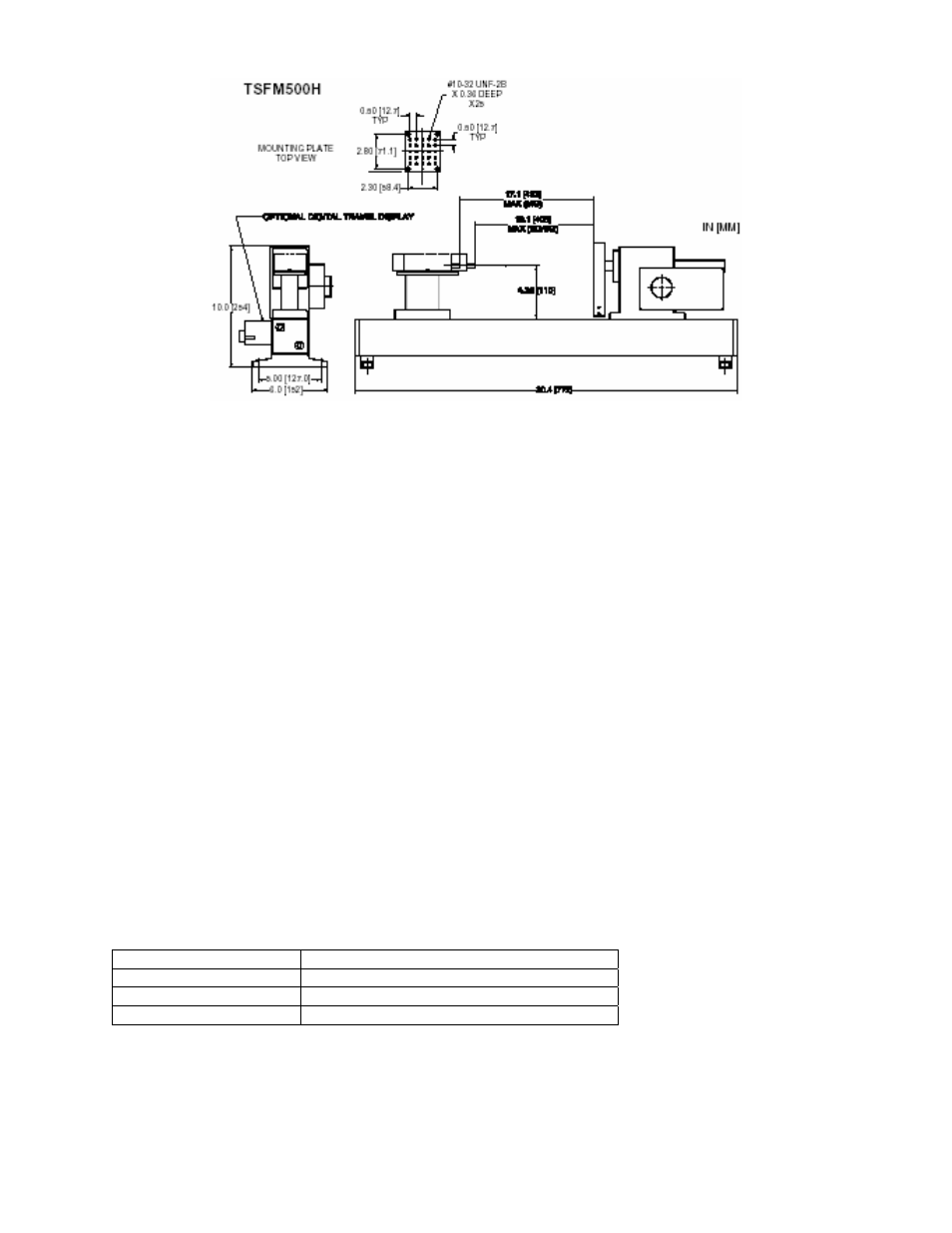

Digital Travel Display Kit

This travel indicator has a 5-digit display (0.0005” [0.01 mm] resolution) and a computer interface for

automated data collection. If purchased at the same time as the test stand, no setup is needed.

Otherwise, it may be easily installed by the user.

SPECIFICATIONS

Load capacity

1000 lb [4500 N]

Maximum travel

4” [102 mm]

Travel rate

0.013” [0.34 mm]/rev

Weight (test stand only)

TSF: 33 lb [14.5 kg], TSFH: 27 lb [12.3 kg]