Hydraulic pressure relief, Assembly, Assemble selector valve – Great Plains Hydraulic Kit User Manual

Page 3

Great Plains Mfg., Inc.

Installation Instructions

3

2014-04-15

194-033M

Hydraulic Pressure Relief

High Pressure Fluid Hazard:

Only trained personnel should work on system hydraulics!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin, causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs,

see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene will

result.

Installation of this kit may require, at a later step, breaking

sealed hydraulic connections at quick-disconnect

couplers. It is crucial to safety that these lines be

depressurized.

3.

If the available tractor has hydraulic circuits with

“float” capability, connect the Transport and Opener

Lift circuits, and relieve any residual system pressure

by floating the circuits.

If no suitable tractor is available, “crack” (carefully

loosen) the connections for both Lift circuits the at

the bleeding points specified in the drill Operator

manual. Leave them cracked for later bleeding.

Assembly

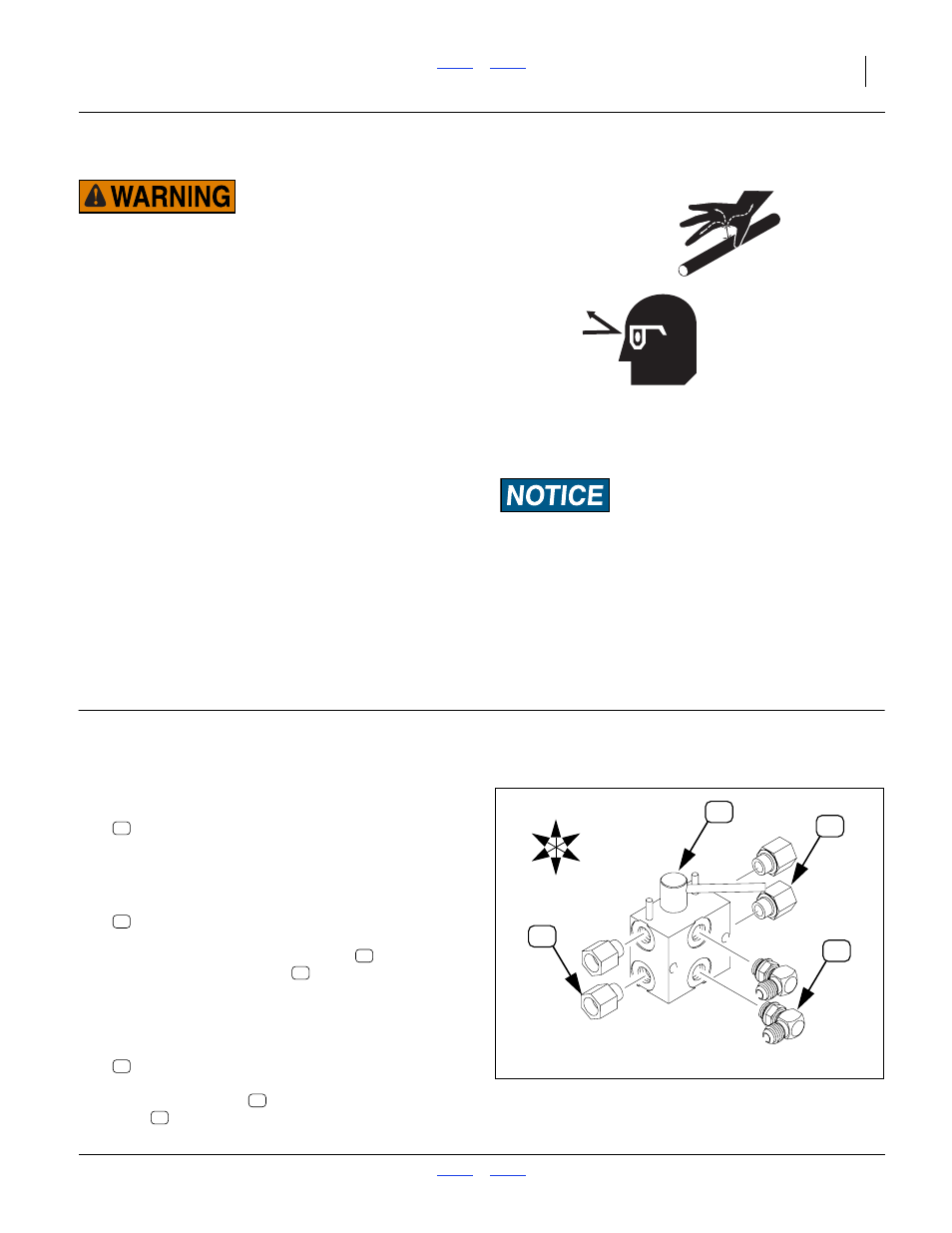

Assemble Selector Valve

Note: Do not use thread sealant on ORB fittings.

Select: one new

810-274C DOUBLE SELECTOR VALVE 3/4FORB

The face openings of the valve are to machine left

after installation.

5.

Select: two new

811-063C EL 3/4MJIC 3/4MORB

Install the ORB ends of the elbows

in the face

(center) of the valve body

(“1” and “2” are

stamped into the valve body at those ports). Before

tightening the jam nuts, orient the JIC ends so that

they face forward when the valve is mounted.

6.

Select: four new

811-021C AD 1/2FNPTS 3/4MORB

Install the adaptors

in the end ports of the valve

body

(ports stamped “1A”, “1B”, “2A” and “2B”).

Bleed only at:

JIC (Joint Industry Conference, 37

°

flare) or

NPT (National Pipe Thread, tapered) fittings.

Never bleed at:

ORB (O-Ring Boss) or

QD (Quick Disconnect) fittings.

Figure 3

Valve and Fittings

27024

U

D

F

B

L

R

19

22

20

20

19

22

22

19

20

20

19