Drive system adjustment – Great Plains ADC2250 Operator Manual User Manual

Page 39

37

Section 3 Adjustments

7/28/10

Model 2250 Air Drill Cart 167-033M

Great Plains Mfg., Inc.

Drive System Adjustment

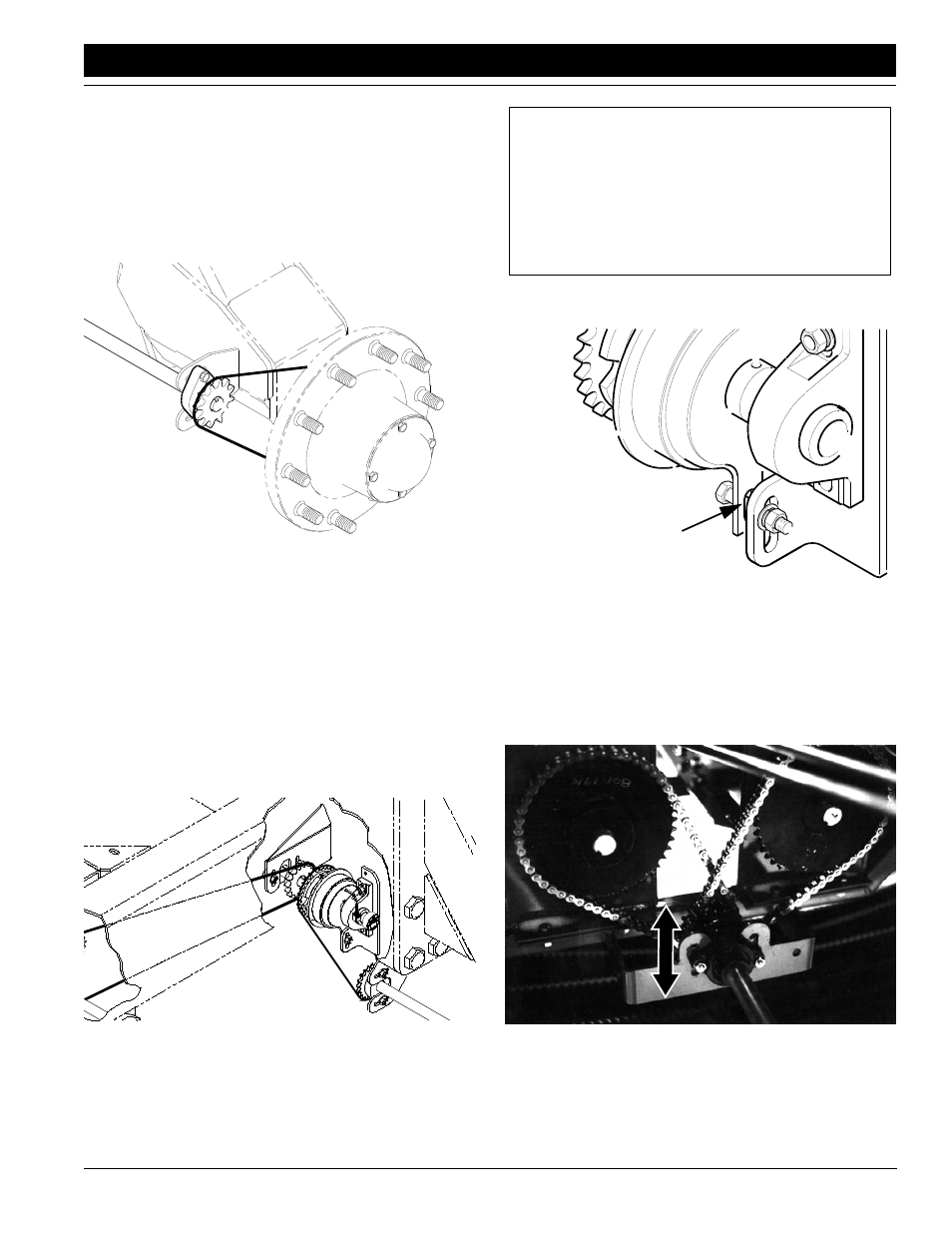

Chain from Hub to Main Jackshaft

Check the chain slack. Chain should have 1/4” - 3/8” slack

at the midpoint of the span. Adjust the tension as needed

by loosening the bearing support bolts and sliding shaft

forward or rearward, see Figure 3-10.

Check tension on the chain from the jackshaft to the clutch

if any adjustments are made.

Drive Chain from Main Jackshaft to Clutch

1.

Make sure both sprockets are aligned. If they are not,

loosen the set screws holding the drive sprocket in

place and move the sprocket over until they are

aligned. Re-tighten the set screws.

2.

Check the tension. Rear span of the chain should

have 1/4” slack at the midpoint - do not overtighten, re-

fer to Figure 3-11. Loosen bolts holding the clutch

shaft bearings and slide the shaft up or down to ad-

just. Tighten bolts. Be sure clutch shaft is kept parallel

with the main jackshaft.

Drive Chain from Gearbox Jackshaft to Gearbox

Check the tension. The rear span should have 3/8” slack

at the midpoint, refer to Figure 3-13. Loosen the bolts

holding the shaft bearings and move in slots to adjust. Re-

tighten the bolts.

Chain from Hub to Main Jackshaft

Figure 3-10

14916

Clutch Input Chain Adjustment

Figure 3-11

14885

NOTE: The electric clutch anti-rotation tang must be

a loose fit over the stop bolt. If the clutch shaft is

moved to adjust the chain tension be sure to check

the stop bolt. The stop bolt can be moved in its slot to

ensure a loose fit or to get greater chain adjustment

if needed. It is very important that the bolt is not tight

against either end of the slot in the clutch tang to en-

sure long clutch life, refer to Figure 3-12

14855

Clutch Anti-rotation Tang and Stop Bolt

Figure 3-12

Loose fit

Gearbox Input Chain Adjustment

Figure 3-13

14870