Plumbing operations – Great Plains 3P-FF900 Operator Manual User Manual

Page 24

3P-FF600, 3P-FF800 and 3P-FF900

500-643M

12/8/2009

22

Plumbing Operations

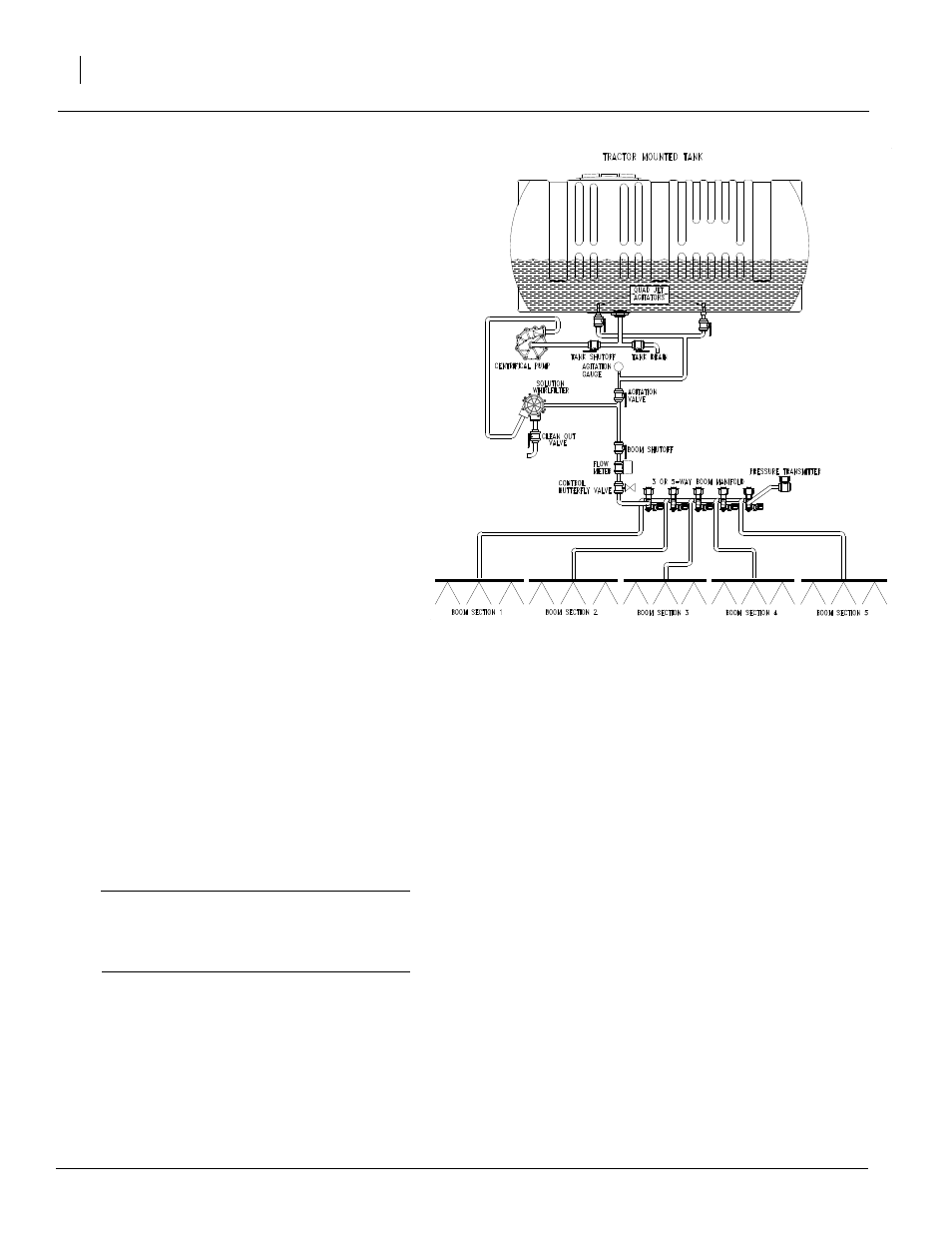

Refer to Figure 3

The basic plumbing diagram is shown for the

sprayer. A basic knowledge of how the sprayer is

plumbed will help you to understand how to oper-

ate your Great Plains Sprayer. Throughout this

manual, the components on this diagram will be

described with the terminology labeling these

components.

Fluid is drawn out of the sump in the tank and

passes through the pump. From the pump it pass-

es through the solution whirlfilter

®

and filters out

or grinds up all undissolved chemical and solid

particles. The fluid then passes through either the

Control Butterfly Valve or the Flow Meter.

The Control Butterfly Valve controls how much flu-

id goes to the boom. This is regulated by the

Raven SCS 450 or 440 controller. The fluid pass-

es through the Flow Meter and proceeds to the 3

or 5-Way Boom Manifold valves. If a Boom Valve

is on the fluid passes to its perspective Boom Sec-

tion and is sprayed out the individual nozzles.

The agitation can be set by adjusting the agitation

pressure valve while the pump is at operating

speed. Refer to Application Guide to adjust the

agitation.

To operate the hydraulic pump, first make sure

that the hydraulic hoses are routed correctly so

that the pump turns in the correct direction. See

the “Hydraulic Pump Hook-up on page 15, for

more details. To run the pump, push the hydraulic

lever in the “down” position. When you want to

stop the pump, push the hydraulic lever in the

“float” position.

IMPORTANT: Do not move the hydraulic lever

to the neutral position while the hydraulic

pump is running. To do so may cause damage

to the hydraulic pump.

Figure 3

Plumbing Diagrams Polyethylene Tank

22903