Hydraulic pump hook-up – Great Plains 3P-FF900 Operator Manual User Manual

Page 17

12/8/2009

500-643M

15

Preparation and Setup

Be certain that tractor lift capacity is adequate and that

tractor is weighted to maintain steering control. Failure to

do so may cause loss of vehicle control. Refer to tractor

specifications for tractor lift capacity and “Specifications

and Capacities,” page 42, for required lift capacity. Con-

sult the tractor’s operator’s manual for tractor weighting

recommendations.

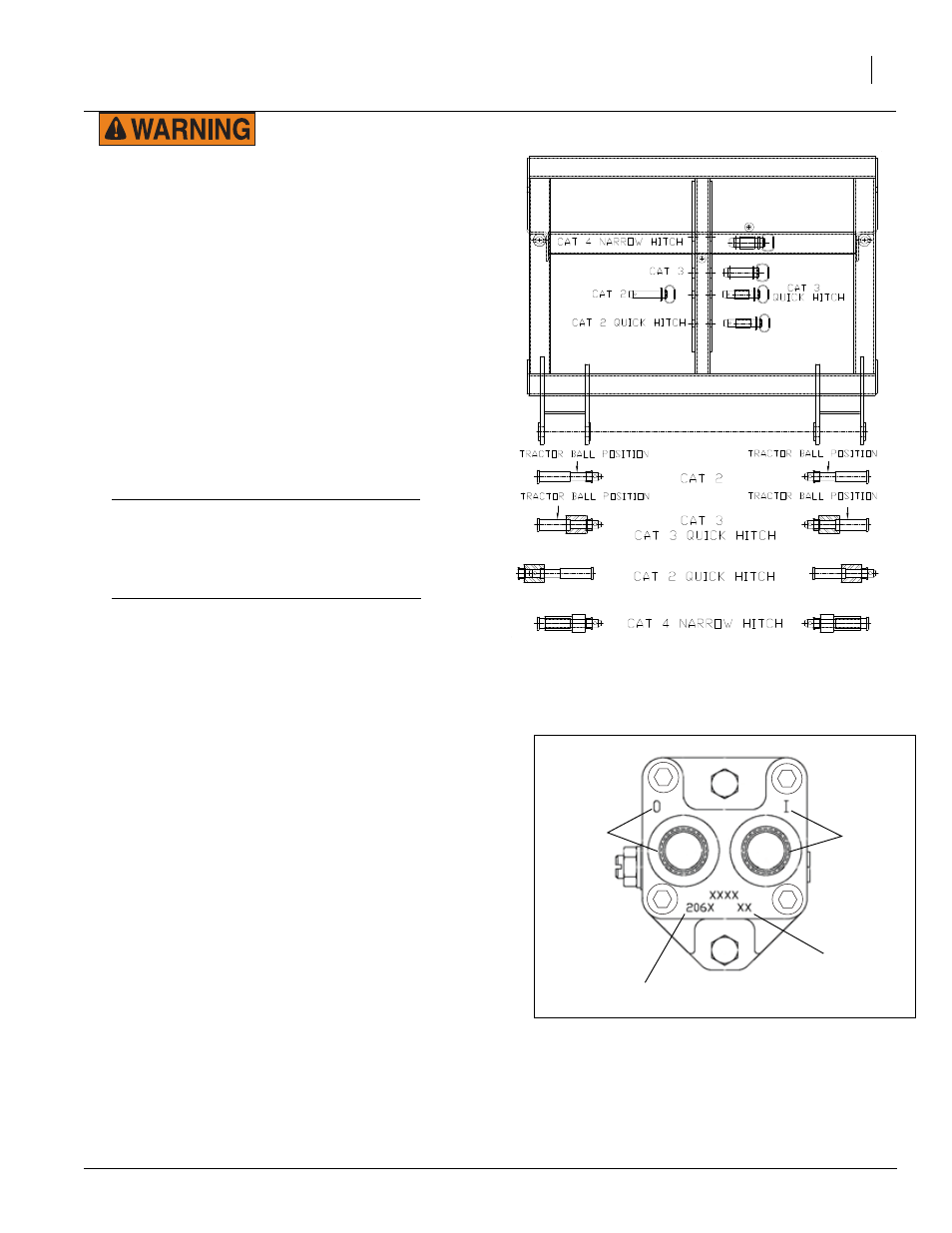

1.

Determine the pin and spacer orientation needed

for the tractor, and securely fasten the hitch pins.

2.

Mount the 3-Point Sprayer to a tractor with the cor-

rect pin mountings determined from instruction

Step 1. Make sure that the sprayer frame is level so

that after the boom is assembled, it won’t hit the

tractor cab when the boom is folded or raised.

IMPORTANT: The category 4 narrow hitch (CAT IV-

N) spacers are not standard parts supplied with the

3-Point Sprayer.

Order 501-011S from a Great Plains dealer for the

Cat IV-N spacers.

NOTE: Be sure that the top 3-Point link is adjusted cor-

rectly so that the frame is level in operating position but

will not hit the cab in transport. The tractor 3-Point arms

should be adjusted to keep the sprayer level from side

to side with lift arm rigid.

12654

Pin & Spacer Configuration

Hydraulic Pump Hook-Up

The hydraulic motor used on all liquid pumps is a 7 gpm

motor. If the tractor used on the sprayer does not have

the capabilities to adjust the remotes down to this flow,

then a hydraulic flow divider kit must be installed so that

flow can be controlled and to prevent operating the

pump at excessive speeds. See a Great Plains dealer.

To hook up the pump conduct the following instructions:

The pressure hose coming out of the tractor remotes

must be connected to the motor inlet port (“I” on current

pumps; “A” on older pumps, Base end on hose label),

and the return line connected to the motor outlet (“O”

on current pumps, “B” on older pumps, Rod end on

hose label). Before operating, place a stop in the neu-

tral position for the tractor hydraulics so that the hydrau-

lic lever can only be moved to the float and down

positions. Refer to the tractor’s operator manual or trac-

tor dealer on information for the neutral stop.

NOTE: Do not move the hydraulic lever into the neutral

position while the hydraulic pump is running. To do so

may cause damage to the hydraulic pump.

Figure 1

Ace Pump Connections

27141

Date Code

Motor Model (204N,206N,210N)

Inlet Port

Outlet Port