Wing turnbuckle 586-295s, Wing turnbuckle 586-446s, Gang angle adjustment – Great Plains 4000TM Operator Manual User Manual

Page 22: Refer to figure 14, Or wing tur, Refer to, Figure 15

18

3500-4000TM

Great Plains Manufacturing, Inc.

586-537M

12/03/2013

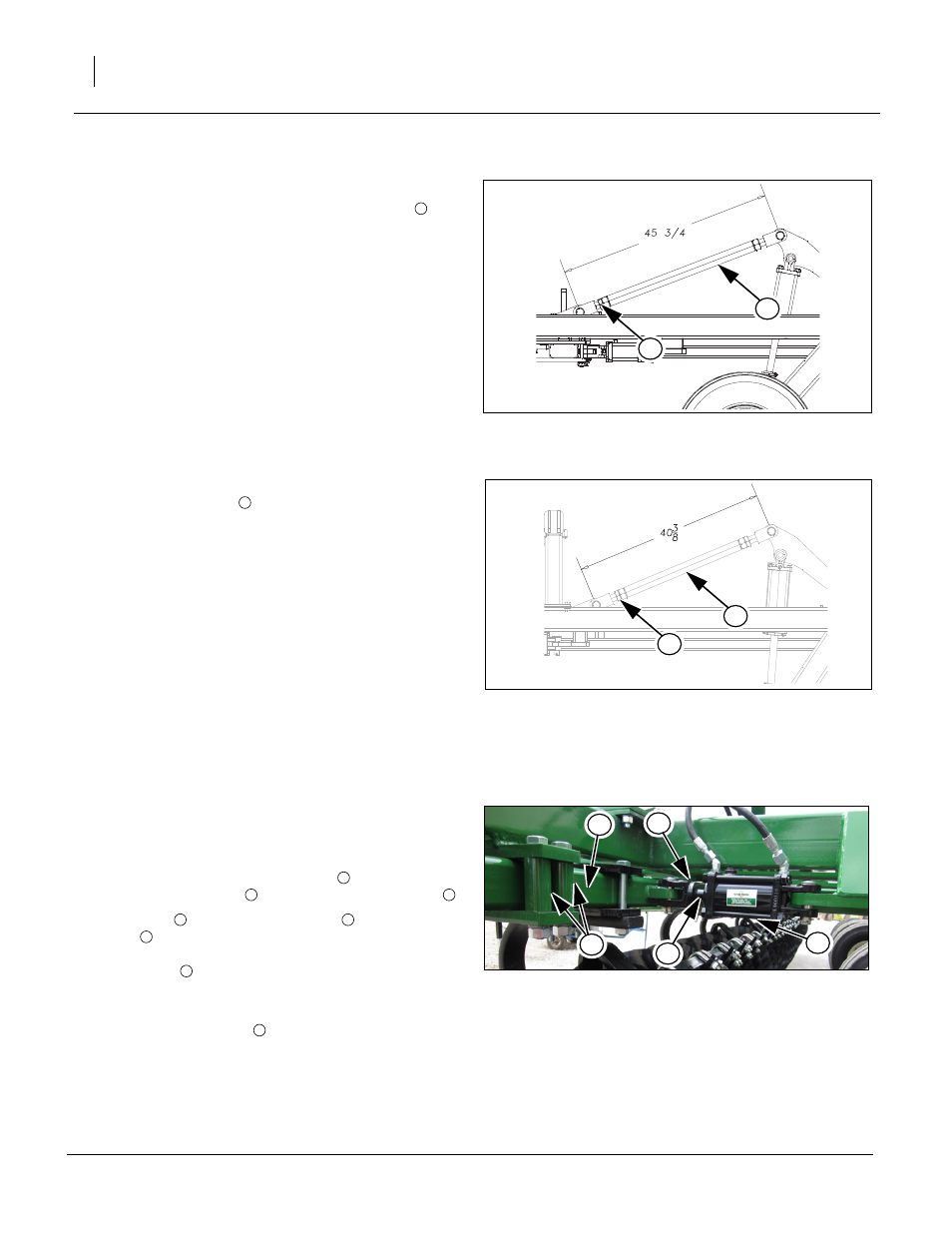

Wing Turnbuckle 586-295S

17. Models 4000 (outer wing), the wing turnbuckle

should

be pre-set at 45 3/4” as shown.

Wing Turnbuckle 586-446S

Refer to Figure 15

18. The wing turnbuckle

should be pre-set at 40 3/8” as

shown.

19. Once machine is leveled side to side, any further adjust-

ment in the field should be done with the hydraulic down

pressure.

20. If running gangs at an angle and the wings are going too

deep, then you should not run down pressure at all.

Switch hydraulic to the float position.

Note: If wings are running too high, increase hydraulic down

pressure setting, too low, decrease down pressure set-

ting. See “Hydraulic Down Pressure 3500” on

page 21 or “Hydraulic Down Pressure 4000” on

page 22 for initial setup and operation.

Gang Angle Adjustment

Note: Check gang angle adjustment when machine is new

and annually after, as wear may occur

21. With front gang adjusting cylinders

in the full retract

position the gang bar

should be 1/8” from tubes

.

22. If gang bar

is not 1/8” from tubes

loosen allen

screw

on clevis on rod end of cylinder (there are two

flat spots on rod to get wrench on to adjust) and shorten

cylinder rod

by turning cylinder rod to bring gang bar

closer and lengthen clevis to get cylinder to retract all

the way.

23. Re-tighten allen screw

when adjustment is made.

Figure 14

Wing Turnbuckle 586-295S

42395

2

1

2

2

Figure 15

Wing Turnbuckle 586-446S

42395

1

2

Figure 16

Front Gang Angle Adjustment

42251

4

2

3

1

5

1

2

3

2

3

4

5

4