Great Plains 2420P Operator Manual User Manual

Page 49

2012-04-17

118-769M

47

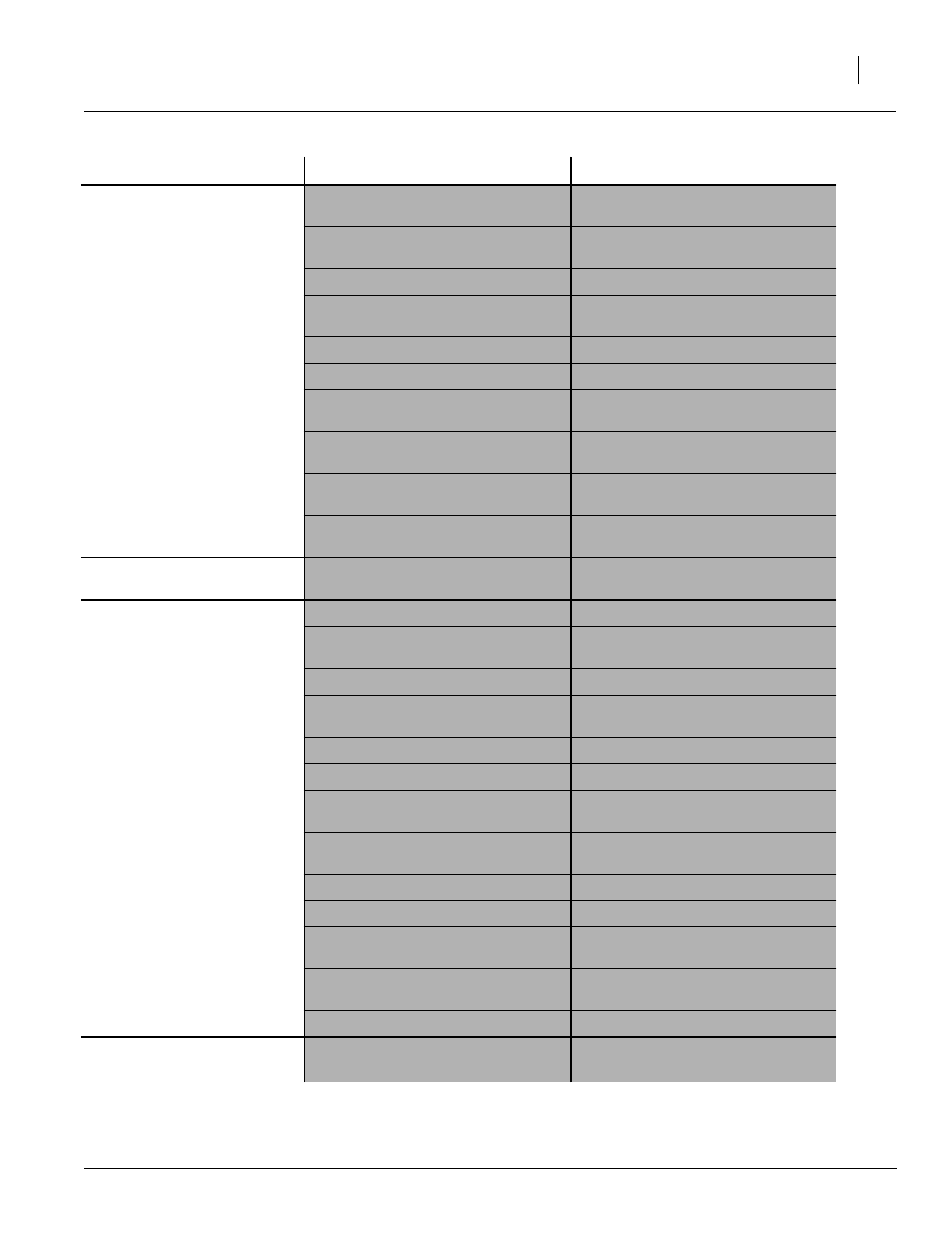

Troubleshooting

Drill boxes do not empty

evenly

Right and left hand seed rates are not

set the same.

Readjust rates, see Seeding Rate

Chart.

Tire sizes or tire inflation not equal on

right and left gauge wheels.

Correct tire size or tire inflation, page

90.

Meter(s) are shut off.

Open meter(s).

Opener seed tube plugged.

Lift up drill, expose bottom of seed

tube and clean out with wire.

Sliding seed tube plugged.

Clean out sliding seed tube.

Drive chains damaged or missing.

Replace drive chains.

Drive torque requirements different

on right and left gauge wheel drives.

Check gauge wheels and tires.

Unequal number of sliding seed tubes

in each box compartment.

Planting around fields vs. back-and-

forth.

Correct planting operation.

Rough field conditions may move

seed in the box.

Chain

Debris in retainer clip

Be sure retainer clip is facing oppo-

site way of chain travel

Press wheel or openers plug-

ging

Planting conditions too wet.

Wait until drier weather.

Drill not running level front-to-back in

the field.

Readjust top link to level drill.

Drill frame height incorrect.

Adjust drill frame height, page 30.

Coulters not set deep enough to cut

residue.

Check coulter adjustment in hitch

operator’s manual.

Opener set too deep.

Opener spring force too high.

20 Series Openers press wheel spring

force too high.

20 Series Openers 1 x 12 press wheel

stagger adjustment not correct.

Correct press wheel stagger.

Backed up with drill in the ground

Clean out and check for damage.

Failed disk bearings

Replace disk bearings.

Disk blades worn.

Adjust or replace disk blades, page

55.

20 Series Opener side depth wheels

not adjusted correctly.

Scraper worn or damaged.

Replace scraper.

Drill is not pulling level front-

to-back

Incorrect top link adjustment.

Readjust top hitch link to level drill.

Problem

Cause

Solution