Planting rate, Hydraulic drive meter rate, Planting rate hydraulic drive meter rate – Great Plains YP2425A Material Rate User Manual

Page 14

401-626B

Table of Contents Metric Charts

2012-02-29

12

YP2425A

Table of Contents Metric Charts

Great Plains Manufacturing, Inc.

Planting Rate

Singulated planting employs the seed monitor in

“PLANTER CONTROL” mode.

Hydraulic Drive Meter Rate

Hydraulic drive meter rate is set directly on the seed

monitor in the tractor. Consult the monitor manual for

detailed instructions, which may vary slightly over time

with firmware updates to the monitor system.

Enter/update your planter configuration (width/row-count,

single-row/twin, disk cell count, etc.). Once entered,

specify the population directly in seeds/acre or seeds/ha.

Enter meter RPM limits for your disk (pages 13-20).

Note: For consistent results, and least meter wear, do not

exceed the recommended ground speed.

For step 1 through step 4, any needed data not provided

in this manual can be found in one or more of:

DICKEY-john

®

Quick Start Guide

Planter Operator Manual

Refer to the DICKEY-john

®

IntelliAg

®

Planter/Drill

Control Operator’s Manual for details on setup item.

Note: The monitor must be in User Level 2 to change

some of these parameters.

1.

For a crop not previously planted with this planter,

create a “Material Name” for the crop. Selecting a

named material is a required step in later screens.

2.

Verify, and as needed setup or update the “Material”

record for the singulated seed to be planted.

The table at right lists the parameters that need to be

reviewed or set.

choice/preference when not from meter rpm chart.

3.

Verify, and as necessary setup or update the

“Channel” assigned to the planter’s hydraulic drive.

If the monitor resets to defaults, Gear Ratio may be

incorrect.

Count rows individually for “# Seed Rows”. A twin

pair (if both openers are in use) counts as 2 rows.

“Channel Width” is swath.

4.

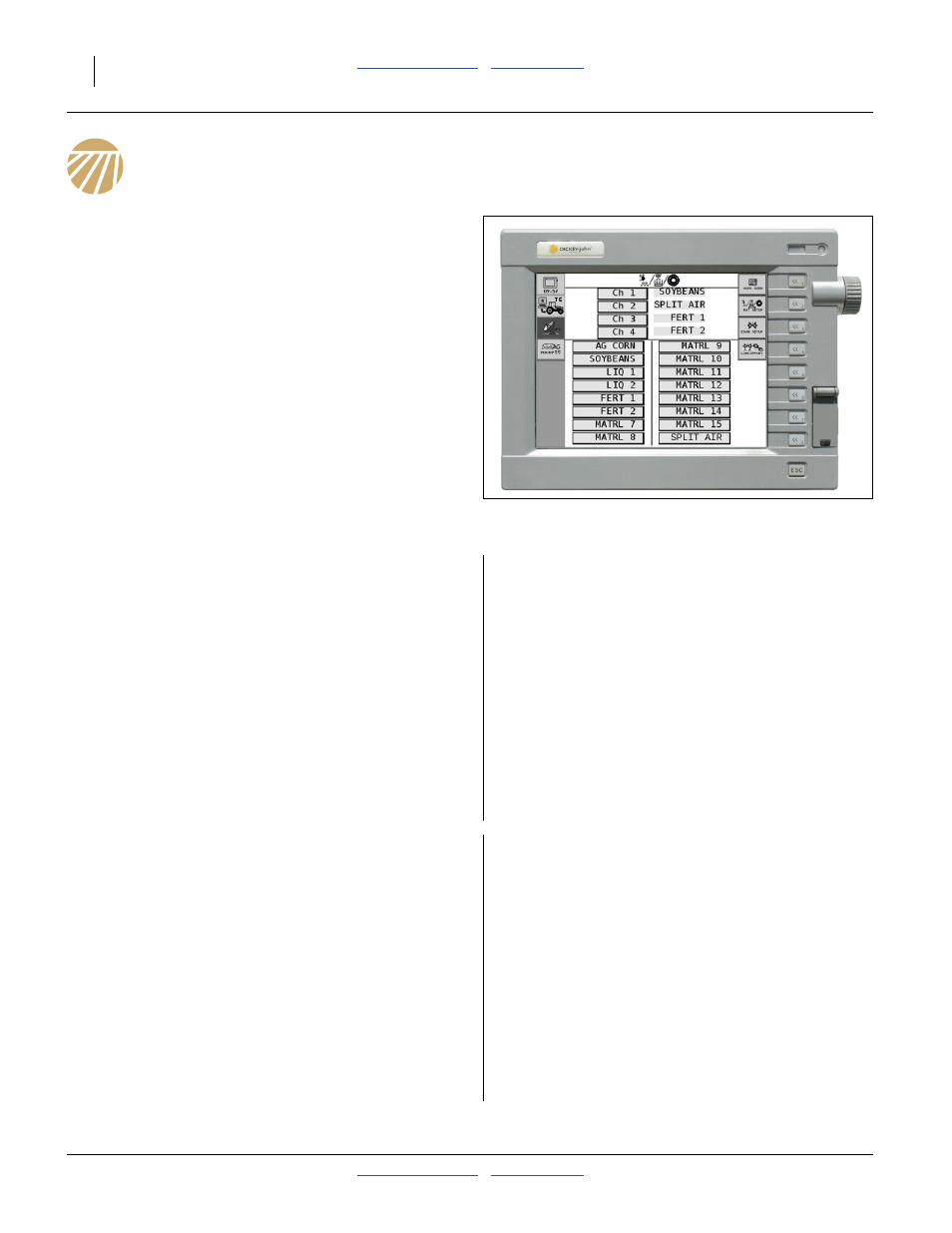

In the Material Library screen, makes sure that the

Material (SOYBEANS in our example) is assigned to

the Channel (CH 1 in our example) which controls

the planter’s hydraulic drive.

5.

Perform a Valve Calibration for the control channel.

6.

Switch the seed monitor from Setup/Configuration

mode to Operate mode. Load seed. Move the planter

to the field.

Figure 4

Typical Control Setup Screen

29750

Material

Data Required

Material Name

Channel

“CH 1”

Type

“PLANTER CONTROL”

Preset Method

“Disabled” unless populations vary

Target Rate

Max Rate

<110% of Target> is suggested

Min Rate

<90% of Target> is suggested

Inc/Dec

“1.0%” is suggested

Seeds Per Rev

Disc Low Limit

Disc High Limit

High Pop Alarm

<“20%”> is suggested

Low Pop Alarm

<“20%”> is suggested

Prod Level Alarm

0

Channel

Data Required

CHANNEL 1

(must be channel specified above)

Type

“PLANTER CONTROL”

Material Name

(must be material name specified above)

Control Mode

Auto

Drive Type

PWM 1

Drive Freq.

100 Hz

Input Filter

50%

Gear Ratio

1.900

Sensor Constant

360

# Seed Rows

Channel Width

Precharge Time

0

Delay Time

0

Flush Enable

Disabled