Press wheel centering, Press wheel assembly with cast wheels – Great Plains 2525F Operator Manual User Manual

Page 45

Adjustments 41

01/23/2012

118-232M

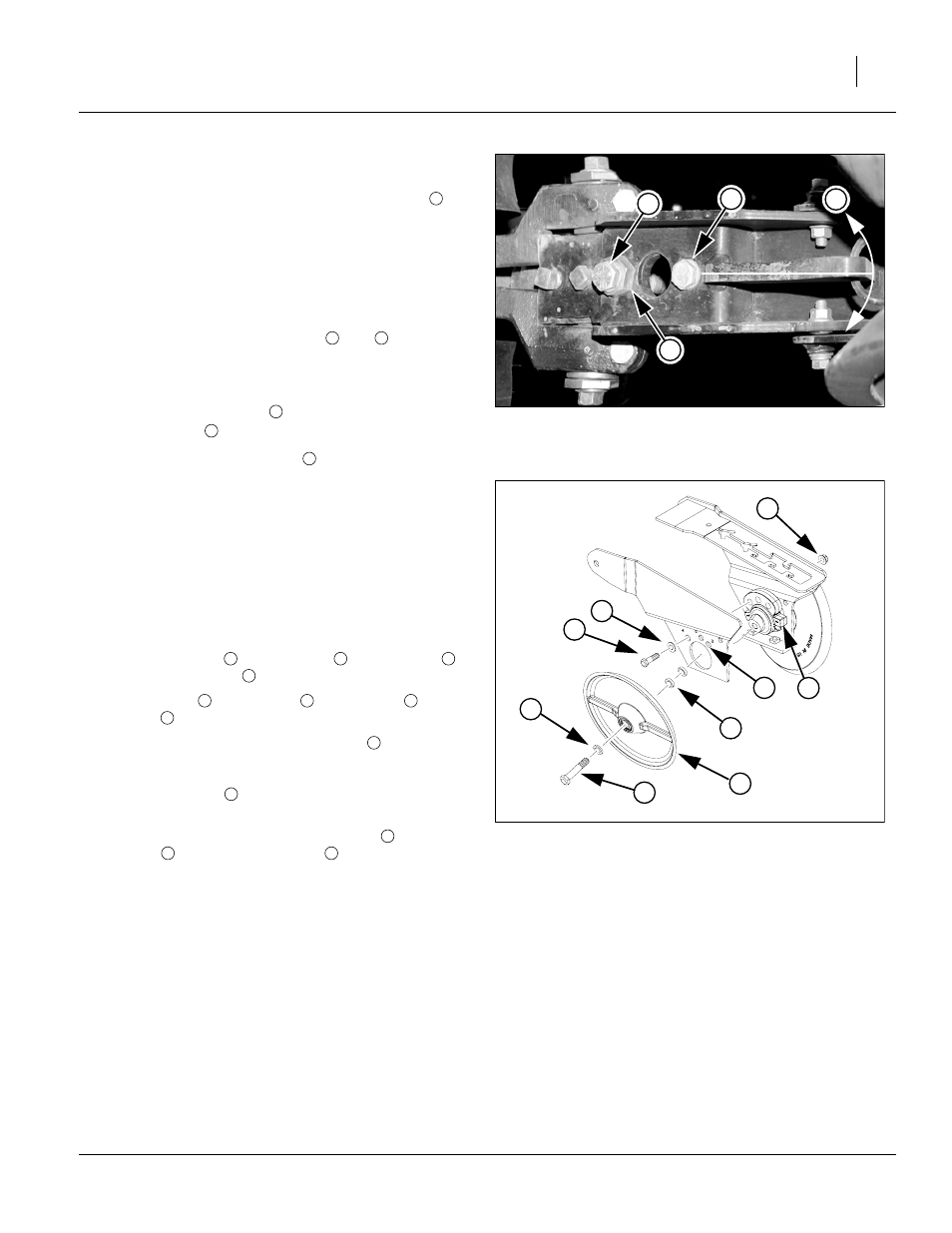

Press Wheel Centering

If one press wheel is running in the seed trench, or the

wheels are not centered over the trench, the angle

of

the press wheel assembly can be adjusted as follows:

Determine how far, and in which direction, the press

wheel assembly needs to move to center the wheels.

2.

Raise drill.

3.

Loosen the

1

⁄

2

in hex-head bolts

and

.

Note: Do not loosen the square-head bolts forward of the

hex-head bolts.

4.

Turn the hex head cam

under the forward hex

head jam bolt

, and move the required amount.

5.

Tighten both hex head bolts

.

Press Wheel Assembly with Cast Wheels

Tight soil may require the need to drag/plow the trench

closed. The factory setting on press wheel assemblies

with cast wheels is 4˚(maximum plow). If the conditions

in your region appear to require less plow, there are two

additional settings: 2˚ (less plow) and 0˚ (no plow). To

change the plow setting:

Raise drill.

2.

Remove the bolt

, lock-washer

and spacers

for the press wheel

.

3.

Remove bolt

, flat washer

and hex nut

for

casting

.

4.

Place a

3

⁄

4

in open end wrench on tab

of casting.

Rotate casting until the desired angle setting (4˚, 2˚

or 0˚) hole lines up with a hole on the press wheel

mount weldment

(only one set of holes will line up

for each setting).

5.

With holes lined up replace casting bolt

and flat

washer

. Secure with hex nut

.

6.

Reinstall press wheel.

If press wheel adjustments do not provide satisfactory

furrow closing, your conditions may require alternate

press wheels. A variety of wheel assemblies are avail-

able. Consult your Great Plains dealer.

FigureSpacer

Figure 57

Press Wheel Centering

25277

3

2

1

4

1

2

3

4

3

3

Null4:

Figure 58

Press Wheel Plow Angle Setting

34011

1

8

7

6

5

3

4

2

9

4