Field operation – Great Plains 2525F Operator Manual User Manual

Page 23

Operating Instructions 19

01/23/2012

118-232M

Field Operation

1.

Hitch drill to a suitable tractor or hitch and stow any

parking stands. See “Hitching Tractor to Drill” on

page 12 or your hitch operator’s manual.

Crushing Hazard:

You may be severely injured or killed by being crushed

between the tractor and drill. Do not stand or place any part of

your body between drill and moving tractor. Stop tractor

engine and set park brake before installing pins.

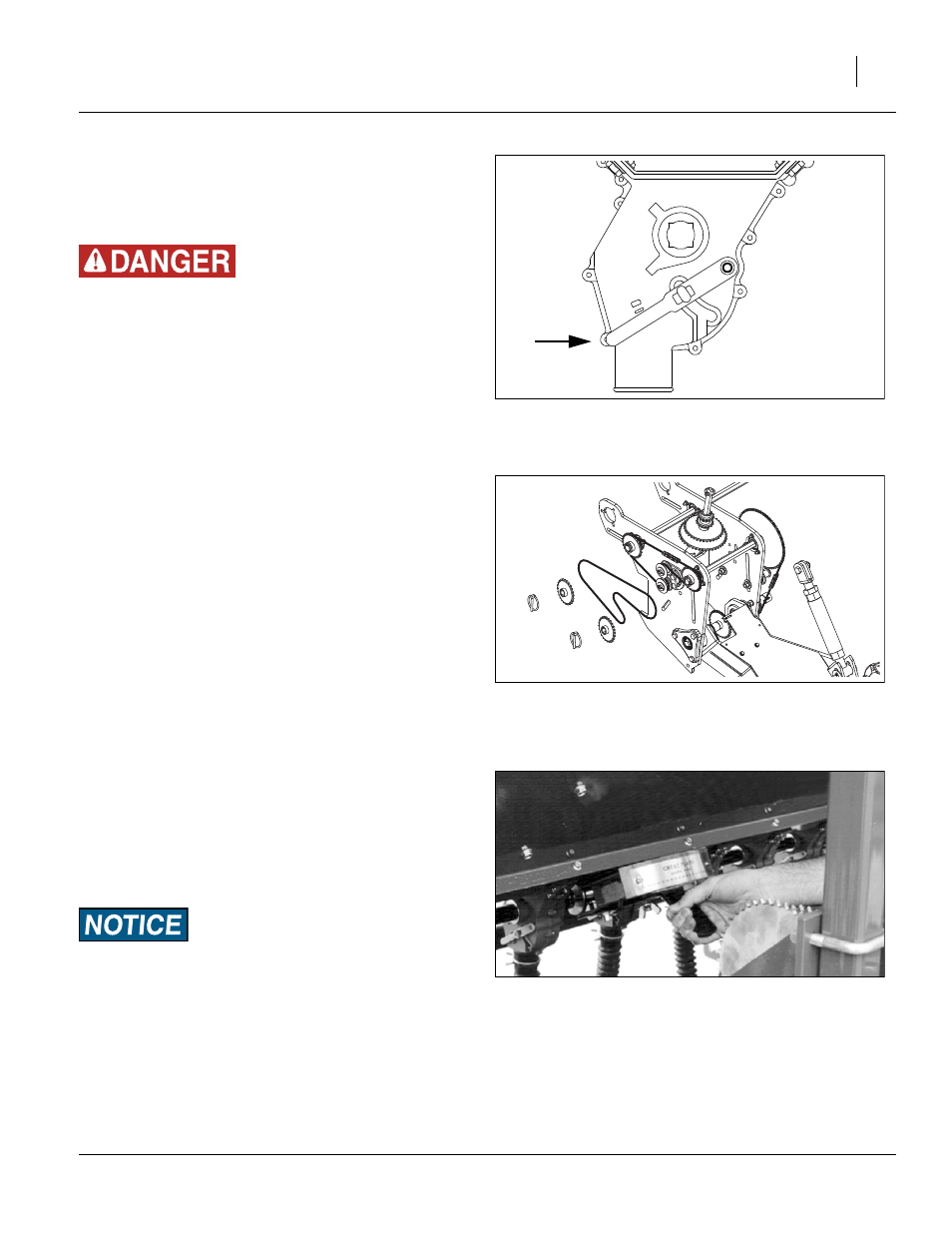

Set all seed Seed Cup Door handles to the same

seed size. See page 24.

Set sprockets identically on both gauge wheel

assemblies, per the Drive Type from the seed rate

charts. See page 23.

Set both Seed Rate Handles to the same rate, per

the Handle Setting from the seed rate charts. See

page 24.

5.

Load box with clean seed.

6.

Raise drill. Rotate gauge wheel. Check that seed

seed cups and seed tubes are working properly and

free from foreign material by looking for seed flow

under each opener.

7.

Record acremeter readout. Subtract initial reading

from later readings to determine acres drilled.

Note: Acremeter readings are imprecise. They also vary

with wheel slippage, field shape, turn-around loop

sizes and other factors.

8.

Pull forward, lower drill and begin seeding.

9.

Always raise drill out of the ground when turning at

row ends and for other short-radius turns. Seeding

will stop automatically as drill is raised.

Machine Damage Risk:

Never back up with row units in the ground. Seed tube and

opener disk plugging is almost certain, and row unit damage is

possible.

If your drill has been exposed to the elements for a

period of time with seed in the boxes, check to make sure

the seed in the seed tubes and seed cups has not

become wet.

FigureSpacer

Figure 15

Seed Cup Door

26211

FigureSpacer

Figure 16

Drive Type

26210

FigureSpacer

Figure 17

Seed Rate

17617